Labkotec SET-OSK2 Oil On Water Detector

General Information

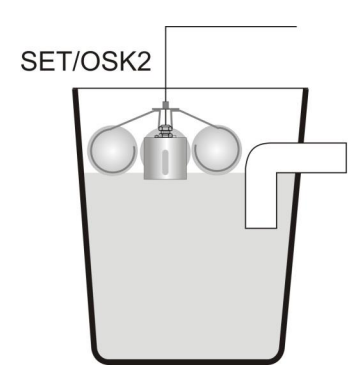

SET/OSK2 is a floating sensor, which provides an alarm of at least a 15 mm thick oil or hydrocarbon layer on water. The most common applications are, for example, inspection shafts and different kinds of basins with an altered liquid level. The sensor must be in the liquid all the time; otherwise, it gives an alarm if it is left in the air. SET/OSK2 is an apparatus of equipment group II, category 1 G. The sensor can be installed in a zone 0/1/2 hazardous area.

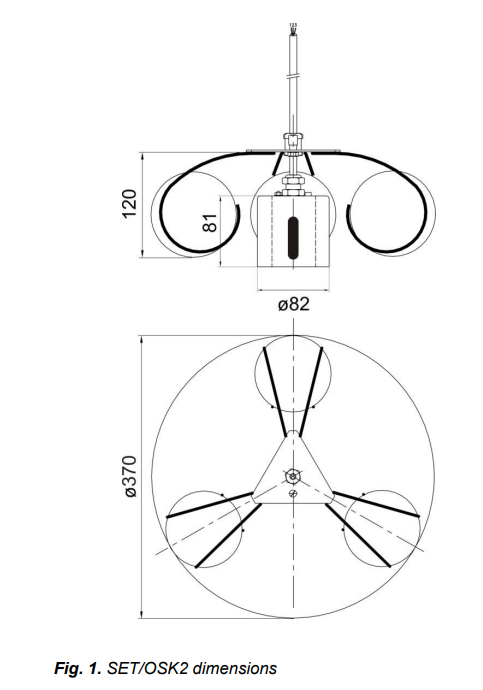

Dimensions

Symbols

- Warning / Attention

- Pay special attention to installations in explosive atmospheres

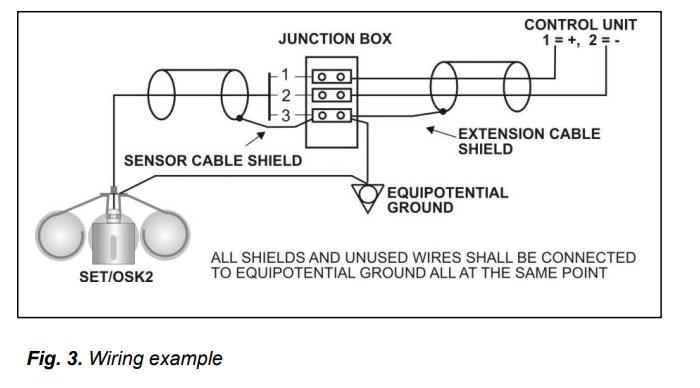

Connections & Installations

The ground connector of the float frame shall be connected to the equipotential ground. Please also refer to the installation instructions of the control unit.

The sensor floats freely on the liquid. Therefore, please use a cable long enough to avoid hanging in the air in critical situations (e.g., when the liquid level decreases).

The sensor floats freely on the liquid. Therefore, please use a cable long enough to avoid hanging in the air in critical situations (e.g., when the liquid level decreases).

EN IEC 60079- 25 Electrical apparatus for potentially explosive atmospheres – Intrinsically safe electrical system “i, EN IEC 60079-14 Electrical apparatus for explosive gas atmospheres.

Switching Point

Adjusting the switching point is done as follows.

- Let the sensor float freely on the water

Too sensitive settings cause unnecessary alarms if there are waves in the liquid. To test the function of the sensor, lift up the sensor totally in the air. This should cause an alarm.

Sensor Not Working

If the sensor is located in a hazardous area, an Ex-classified multimeter must be used, and the Ex-standards mentioned in the chapter

Repair & Service

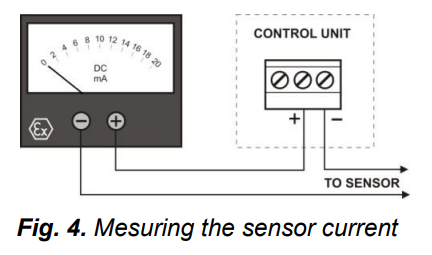

The voltage between connectors 1 and 2 in the control unit should be 10,5…12V. If the voltage is correct, measure the sensor current as follows.

- Connect the ammeter according to the figure Labkotec SET-OSK2 Oil On Water Detector below by disconnecting the conducting wire 1 from the central unit.

- Measure the current.

Sensor current in different conditions.

- clean and dry sensor in air 5… 6 mA

- sensor entirely in water 12…16 mA

Technical Data

| SET/OSK2 sensor | |

| Control units | Labkotec SET control units |

| Cable | Shielded, oil-proof instrumentation cable 3 x 0,5mm2 Ø 5,7mm. Standard length is 5m. The maximum pair resistance of the cable should not exceed 75 Ω. |

| Temperature Operational Safety | -25 C…+60 C -25 C…+60 C |

| Materials | AISI 316, PVC |

| EMC Emission Immunity | EN IEC 61000-6-3 EN IEC 61000-6-2 |

| IP-classification Sensor Junction box | IP68 IP67 |

| Ex-luokitus ATEX Special conditions (X) | II 1 G Ex ia IIA T5 Ga VTT 03 ATEX 009X Ta = -25 °C…+60 C The sensor cable can be extended with the junction box type LJB3-78-83 or LJB2-78-83. |

| Ex-connection values | Ui = 18 V I = 66 mA Pi = 297 mW Ci = 3 nF Li = 30 µH UN 9…18 V |

| Operating principle | Capacitive |

| Manufacturing year: Please see the serial number on the type plate | xxx x xxxxx xx YY x where YY = manufacturing year (e.g. 19 = 2019) |

EU Declaration of Conformity

We hereby declare that the product named below has been designed to comply with the relevant requirements of the referenced directives and standards.

Product

- Level sensor SET/OS2, SET/OSK2

Manufacturer

- Labkotec Oy

- Myllyhaantie 6

- FI-33960 Pirkkala

- Finland

Directives

The product is in accordance with the following EU Directives:

- 2014/30/EU Electromagnetic Compatibility Directive (EMC)

- 2014/34/EU Equipment for Potentially Explosive Atmospheres Directive (ATEX)

- 2011/65/EU Restriction of Hazardous Substances Directive (RoHS)

Standards

EMC

- EN IEC 61000-6-2:2019

- EN IEC 61000-6-3:2021

ATEX

- EN IEC 60079-0:2018

- EN 60079-11:2012

- EC-type examination certificate: VTT 03 ATEX 009X.

Notified Body

- VTT Expert Services Ltd, Notified Body number 0537.

RoHS

- EN IEC 63000:2018

Signature

- This declaration of conformity is issued under the sole responsibility of the manufacturer. Signed for and on behalf of Labkotec Oy.

Customer Service

- E-mail: labkonet@labkotec.fi

- Tel: +358 29 006 6066.

- Address: Myllyhaantie 6, FI-33960 Pirkkala, Finland

© 2025 Labkotec.fi.

FAQs

How does the SET-OSK2 detect oil on water?

The apparatus detects the difference in the dielectric characteristics of water and oil using a capacitive sensing approach. The sensor recognises when a coating of oil appears on top of water and triggers an output signal or alert.

Does the SET-OSK2 require a specific control unit to operate?

Indeed. Incompatible control units can cause damage or improper operation.

How is the SET-OSK2 powered?

Low-voltage models may be available; however the control unit (SET/OSK2) normally runs on 230 VAC. Before installing, always check the voltage listed in the user manual and on the device label.

Is the SET-OSK2 suitable for use in hazardous or ATEX environments?

For usage in flammable or explosive environments, certain SET-OSK2 sensor models are certified by ATEX. Before installing in certain areas, be sure your particular model is certified.

How often should the SET-OSK2 sensor be cleaned?

The application determines how often to clean. Check the sensor once a month in situations that are greasy or unclean. Avoid using solvents, abrasives, or high-pressure jets when cleaning; instead, use a gentle cloth and a mild detergent.