Ronix RC-5012 50L Air Compressor

Safety Instructions

- Save all warnings and instructions for future reference.

- Keep the work area clean and well-lit. Cluttered or dark areas invite accidents.

- Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control. - Power tool plugs must match the outlet. Never modify the plug in any way.

- Don’t use any adaptor plugs with earthed (grounded) power tools.

- Unmodified plugs and matching outlets will reduce the risk of electric shock.

- There is an increased risk of electric shock if your body is earthed or grounded.

- Don’t expose power tools to rain or wet conditions.

- Water entering a power tool will increase the risk of electric shock.

- When operating a power tool outdoors, use an extension cord suitable for outdoor use.

- Using a cord suitable for outdoor use will reduce the risk of electric shock.

- Stay alert, watch what you are doing, and use common sense when operating a power tool.

- Don’t use a power tool while you are tired or under the influence of drugs, alcohol, or medication.

- A moment of inattention while operating power tools may result in serious personal injury.

- Use personal protective equipment. Always wear eye protection.

- Remove any adjusting key or wrench before turning the power tool on.

- A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

- Don’t overreach. Keep proper footing and balance at all times.

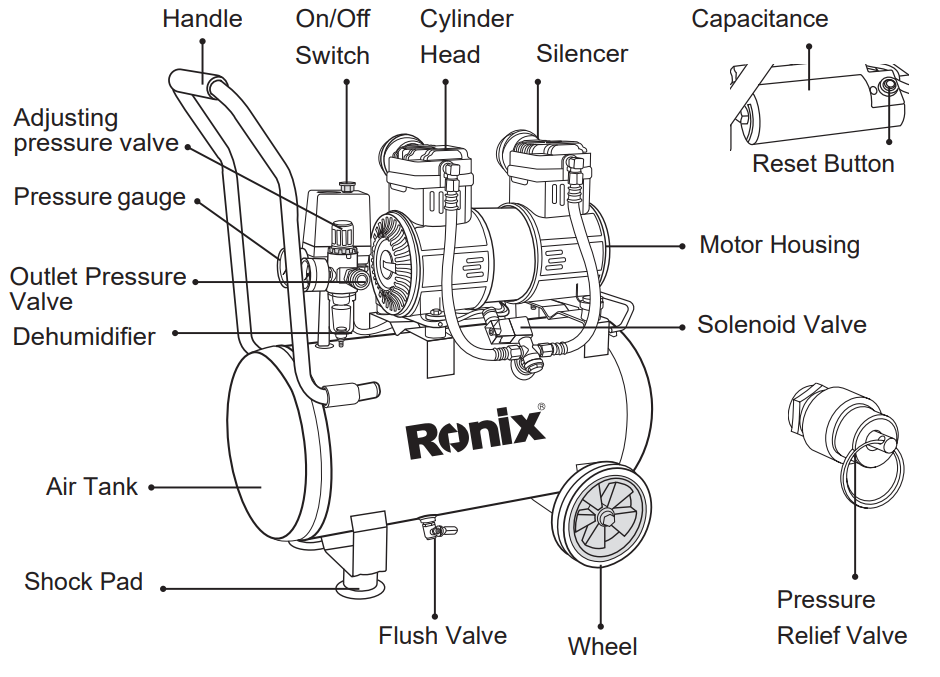

Part List

Use & Care

- Do not exceed the pressure rating of any component in the system.

- Protect material lines and air lines from damage or puncture.

- Keep hoses and power cords away from sharp objects, chemical spills, oil, solvents, and wet floors.

- Check the tank before each use, making certain all connections are secure.

- Do not use if a defect is found.

- Release all pressures within the system slowly. Dust and debris may be harmful.

- Store idle air compressors out of the reach of children and other untrained persons.

- Air compressors are dangerous in the hands of untrained users.

- Maintain air compressors with a car. Follow maintenance instructions.

- Properly maintained products are easier to control.

- If damaged, have the air compressor serviced before using.

- Many accidents are caused by poorly maintained products.

- Keep the exterior of the air compressor dry, clean and free from oil and free from oil and grease.

- Always use a clean cloth when cleaning.

- Never use brake fluids, gasoline, petroleum-based products, or any strong solvents to clean the unit.

- Following this rule will reduce the risk of deterioration of the enclosure plastic.

Service

- Have your power tool serviced by a qualified repair person using only identical replacement parts.

- This will ensure that the safety of the power tool is maintained.

- Follow the instructions for lubricating and changing accessories.

- Keep handles dry, clean, and free from oil and grease.

Assembly

Unpacking

- This product requires assembly. Carefully remove the product and any accessories from the box.

- Use of a product that may have been improperly assembled could result in serious personal injury.

- If any parts are damaged or missed, do not operate this product until the parts are replaced.

- Use of this product with damaged or missing parts could result in serious personal injury.

- Do not connect to the power supply until assembly is complete.

- Failure to comply could result in accidental starting and possible serious personal injury.

Applications

Air compressors are utilized in a variety of air system applications. Match hoses, connectors, air tools, and accessories to the capabilities of the air compressor. For smaller tasks or compact setups, you can also check the Ronix RC-1010 10 Liter Air Compressor for guidance. You may use this product for the purposes listed below:

- Operating some air-powered tools

- Operating air accessories such as air nozzles and tire inflators.

Moving Compressor

\nsure the air compressor is unplugged, and make sure the power cord is secured in the cord wrap.

- Facing the back of the air compressor, grasp the handle firmly with two hands.

- Lift the air compressor toward you until it balances on the wheels.

- Push the unit along to the desired location.

Lower their air compressor unit so that it sits securely on a flat surface.

Break-In Periods

Before first use, run the air compressor at zero tank pressure with the drain valves fully open for 30minutes.

On/Off

- With the air compressor plugged in, pull the power switch to the ON position.

- To turn the air compressor off, push the power switch to the OFF position.

Using Compressor

- Ensure the power switch is in the OFF (O) position and the air compressor is unplugged.

- If not already installed, attach the hose to the compressor

- Attach 6.35 mm (1/4 in.) NPT quick-connect air fitting to the accessory or tool you intend to use.

- Insert the other end of the quick-connect air fitting into the quick coupler on the open end of the hose.

- Connect the power cord to the power supply. Turn the switch ON (1).

- Follow all safety precautions in the air tool manual. You may now proceed to use your air-powered tool.

- Control the amount of air flow with the pressure regulator knob.

- Turning the knob fully counterclockwise will completely stop the flow of air.

Draining Tanks

To help prevent tank corrosion and keep moisture out of the air, used, the air tanks of the compressor should be drained daily.

To Drain

- Turn the air compressor off.

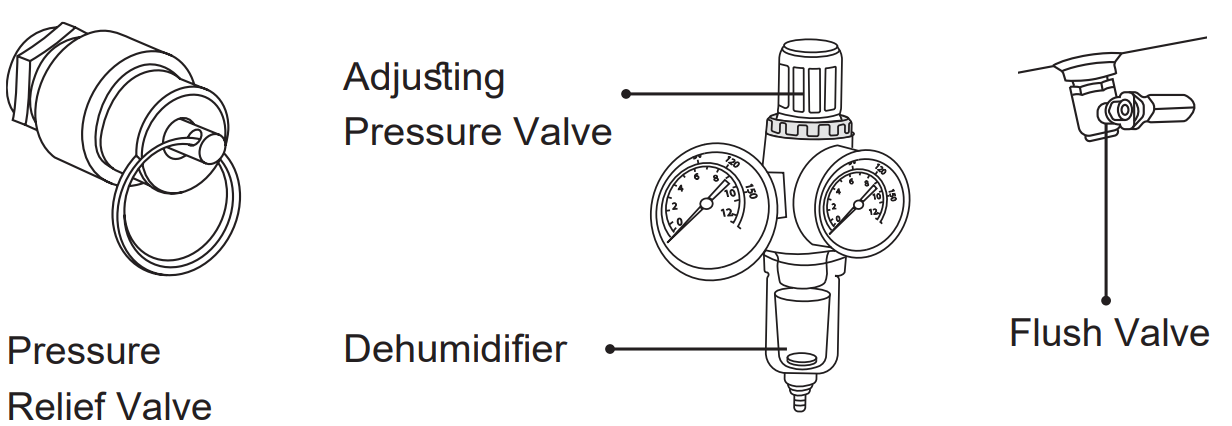

- Pull the ring on the pressure relief valve to release until the pressure gauge reads less than 1.4 bar.

- Release the ring.

- Rotate the flush valve 90 degrees to pour the tank water out.

Dehumidifier Role

The dehumidifier tank absorbs and gathers droplets of water mixed in the compressed air to longers the life of the component working by compressed air.

Check the Valve

- Do not attempt to tamper with the safety valve.

- Anything loosened from this device could fly up and hit you.

- Failure to heed this warning could result in death or serious personal injury.

- The safety valve will automatically release air if the air tank pressure exceeds the preset maximum.

- The valve should be checked before each day of use by pulling the ring by hand.

- Turn the air compressor on and allow the tanks to fill.

- The compressor will shut off when the pressure reaches the preset maximum.

- Turn the air compressor off.

- Pull the ring on the safety valve to release air for three to five seconds.

- The ring pin must be pushed back into position to stop the flow so air at high pressure.

Maintainance

- When servicing, use only identical replacement parts. Use of any other parts may create a hazard or cause product damage.

- Always wear eye protection with side shields. Failure to do so could result in objects being thrown into your eyes, resulting in possible serious injury.

- Always release all pressure, all pressure, disconnect from the power supply, and allow the unit to cool to the touch before cleaning or making repairs on the air compressor.

- Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types of commercial solvents and can be damaged by their use.

- Use clean cloths to remove dirt, dust, oil, grease, etc.

Specifications

| Model | RC-5012 |

| Power | 1680W |

| Voltage | 220-240V |

| Frequency | 50Hz |

| No Load Speed | 2800RPM |

| Air Tank Capacity | 50L |

| Max Pressure | 0.8MPa |

| Air Delivery | 140L/Min |

| Net. Weight | 26.5Kg |

Troubleshooting

| PROBLEMS | CAUSES | SOLUTIONS |

| The current limiting protector cuts out repeatedly | Lack of proper ventilation/ room temperature too high | Move the compressor to a well-ventilated area |

| Wrong gauge wire or length of extension cord | Check for proper gauge wire and cord length | |

| Loose connections (fitting, tubing, etc.) | Check all connections with the soap and water solution and tighten | |

| Air tank pressure drops | Loose drain valve | Tighten the drain valve |

| When the compressor shuts off | Check valve leaking | Take the compressor to the service center. |

| Excessive moisture in | Excessive water in the air tanks | Drain tanks |

| Discharge air | High humidity | Move to an area of less humidity; use an air filter |

| Defective pressure switch | Take the compressor to the service center. | |

| Excessive air usage | Take the compressor to the service center | |

| Compressor runs continuously | Piston rings are worn | Decrease air usage; compressor not Large enough to meet tools’ requirements |

| Replace piston rings; the Air intake filter is blocked. Call customer service for assistance | ||

| Air output is lower than | Broken inlet valves | Tack the compressor to the service center |

| normal | Connections leaking | Tighten connections |

Environmental Instructions

- Dispose of cardboard packaging and polyethylene (PE) bags in the appropriate containers for separate collection of municipal waste according to their description.

- If there are batteries in the device, remove them and separately return them to the collection and storage facility. Return the used device to a suitable collection and storage facility, as the hazardous substances in it may pose a threat to health and the environment.

- Waste electrical equipment is waste that contains substances harmful to humans, animals, and the environment.

- These substances can lead to contamination of the soil, water, or air, and through this they can get into the human body and lead to numerous health ailments, such a vision, hearing, and speech disorders; they can also lead to kidney, liver, and heart damage, and cause skin diseases.

- Harmful substances can also have adverse effects on the respiratory and reproductive systems and lead to cancerous changes. Consumption of plants growing on the contaminated soils, and products made from them, may risk the above-mentioned health effects.

- Do not dispose of the device in the municipal waste container!!! Service: If you wish to purchase spare parts or report any complaints, please contact directly with the seller who issued the receipt directly.

Customer Support

- Address: Lyoner Str. 36 60528 Frankfurt am Main

- Tel:+49 69 310 900 66

- Website: www.ronixtools.com

FAQs

Q: What is the maximum pressure of this compressor?

With a maximum pressure of 8 bar (116 PSI), the RC-5012 is appropriate for the majority of light to medium-duty pneumatic applications.

Q: How long does it take to fill the 50L tank from empty?

The compressor fills the tank from 0 to full pressure in around 3 to 4 minutes under normal circumstances.

Q: Can I run the compressor continuously?

Let the unit rest so the motor may cool down after extended use. Running continuously might shorten motor life and lead to overheating.

Q: What type of oil should I use in the compressor?

Make use of premium compressor oil (SAE 30 non-detergent or ISO VG 100). Before operating, always check the oil level.

Q: Why does my compressor stop automatically?

There is an automated pressure switch on the compressor. When the tank pressure reaches the maximum predetermined level, it cuts off, and when the pressure falls below the restart level, it restarts. This is a standard feature for efficiency and safety.

Q: How do I adjust the output air pressure?

To raise or lower the pressure, turn the pressure regulator knob in a clockwise or anticlockwise direction. To establish the proper level for your tool, always keep an eye on the regulated pressure gauge.