Ronix 2732 1250 W Rotary Hammer

Safety Instructions

Read all instructions for the Ronix 2732 1250 W Rotary Hammer. Failure to follow all instructions listed below may result in electric shock, fire, and/or serious injury. The term “power tool” in all of the warnings listed below refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

Keep the work area clean and well-lit. Cluttered and dark areas invite accidents. Do not operate the Ronix 2732 1250 W Rotary Hammer in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks, which may ignite the dust or fumes. Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce the risk of electric shock. Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges, and refrigerators.

Do not expose power tools to rain or wet conditions. Water entering the power tool will increase the risk of electric shock. Do not abuse the cord. Never use the cord for carrying, pulling, or unplugging the power tool. Keep the cord away from heat, oil, sharp edges, or moving parts. Damaged or entangled cords increase the risk of electric shock. When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

Specifications

The following are the key specifications for the Ronix 2732 1250 W Rotary Hammer, providing detailed information on its performance, capacity, and included accessories:

| Model | 2732 |

| Chuck Type | SDS Plus |

| Chuck Size | 32mm |

| Power | 1250W |

| Impact Energy | 4.5J |

| Frequency | 50-60Hz |

| Voltage | 220-240V |

| Max Capacity in Wood | 40mm |

| Max Capacity in Steel | 13mm |

| Max Capacity in Concrete | 32mm |

| No-load Speed | 800RPM |

| Max Impact Rate | 2600BPM |

| Weight | 5.2Kg |

| Supplied in | BMC |

| Includes | SDS Plus 8x150mm Drill Bit SDS Plus 10x150mm Drill Bit SDS Plus 12x150mm Drill Bit Grease Pot, Auxiliary Ronix Design Handle 14x250mm Point Chisel 14x250mm Flat Chisel Depth Stop Dust Cap |

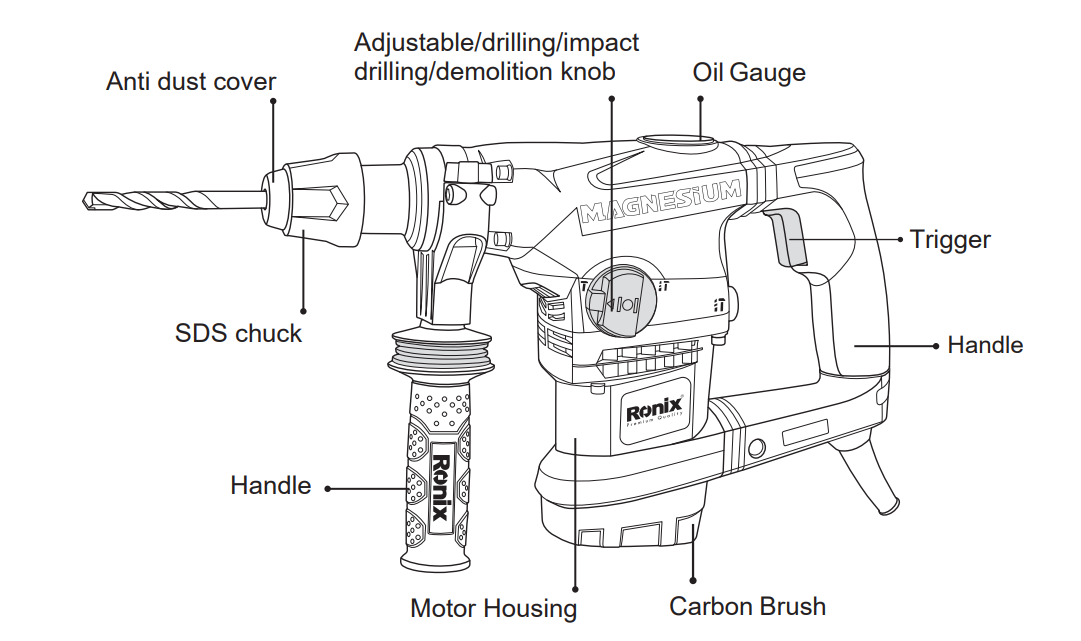

Part List

Service

Tool service for the Ronix 2732 1250 W Rotary Hammer must be performed only by qualified personnel. Service or maintenance performed by unqualified personnel could result in the risk of injury. When servicing the Ronix 2732 1250 W Rotary Hammer, use only identical replacement parts. Follow instructions in the Maintenance section of this manual. Use of unauthorized parts or failure to follow Maintenance instructions may create a risk of electric shock or injury.

Symbols

| V | Volts | |||

| A | Amperes | |||

| Hz | Hertz | |||

| W | Watt | |||

| Kw | Kilowatts | |||

| F | Farads | |||

| Microfarads | ||||

| l | Litres | |||

| Kg | Kilograms | |||

| bar | Bars | |||

| Pa | Pascals | |||

| h | Hours | |||

| min | Minutes | |||

| s | Seconds | |||

| No Load Speed | ||||

| ./min or minˉ¹ | Revolutions Or Reciprocations Per Minute | |||

| Direct Current | ||||

| Alternating Current | ||||

| ² | Two-Phase Alternating Current | |||

| 2N | Two-Phase Alternating Current With Neutral | |||

| 3 | Three-Phase Alternating Current | |||

| Three-Phase Alternating Current With Neutral Rated Current Of The Appropriate Fuse Link In Amperes Time-Lag Miniature Fuselink Where X Is The Symbol For The Time/Current Characteristic, As Given In EN 60127 Protective Earthing At Earthing Terminal, Class I Tools Diameter | ||||

| 0 | Off Position | |||

| IPXX | Ip Symbol | |||

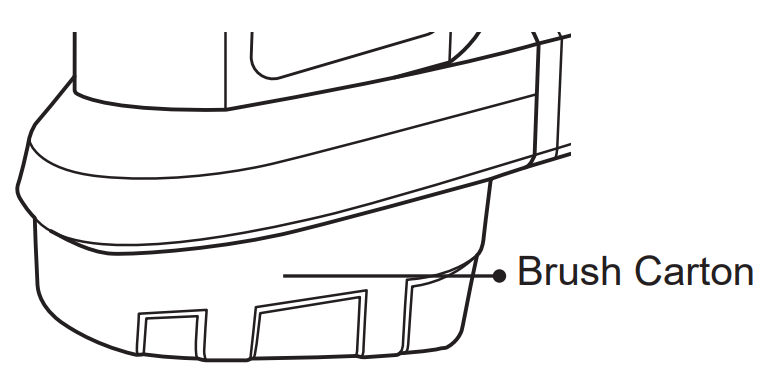

Cartoon Content

| ROTARY HAMMER | ||

| KEY | Description | QTY |

| A | Rotary hammer | 1 |

| B | Chisels | 2 |

| C | Drill bits | 3 |

| D | Oil key | 1 |

| E | Carry case | 1 |

Assembly & Operation

Always make sure the power tool is isolated from the power supply before fitting any attachment Handle. Always make sure the fixed handle is secure before any job takes place, as a loose handle could cause injury.

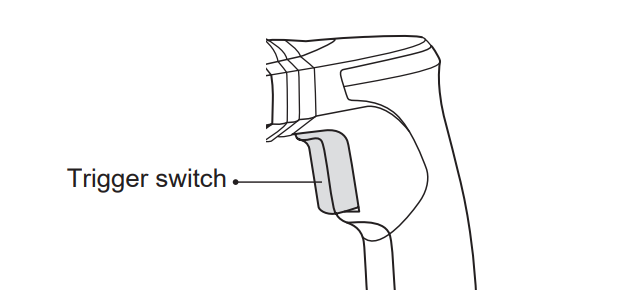

Switching the chisel on/off. The chisel has an On/Off switch built in to tintondle. Holding the chisel with both hands, simply squeeze the trigger and the motor will start. To switch off the release, the trigger.

The electric hammer chisel continues for a few seconds after the trigger has been released, useful when putting it down. Fitting a chisel bit into the Hex housing.

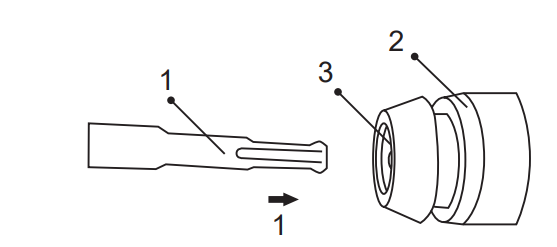

Put the bit into the hex housing and clamp the bit by turning the stop lever half a turn counterclockwise. This will lock the bit in place. Do not use the chisel until you are satisfied the bit is secured.

This electric hammer chisel does not have a reverse direction, so always take care not to force the chisel in case the chisel bit gets stuck. Always make sure you keep the chisel going in and out to remove debris. This chisel does not have a torque facility. It is not recommended to use any tool other than masonry or chisels; do not use metal cutting drills, as this could cause serious injury.

For lighter fastening jobs, you might also find the Ronix 2510 10mm Electric Screw Driver Instruction Manual helpful for guidance on using a compact electric screwdriver alongside your Ronix 2732 Rotary Hammer.

Maintainance

Before oil feeding, always disconnect the plug from the power supply receptacle when maintaining the Ronix 2732 1250 W Rotary Hammer. Since an oil chamber is built into this electric hammer chisel, the Ronix 2732 1250 W Rotary Hammer can be used for approximately 20 days without supplying lubrication oil, assuming it is used continuously 3–4 hours daily. Feed oil into the oil tank as described below before using the hammer chisel.

- When the chisel is held upright, look through the oil gauge window to see if oil is visible. If no oil shows, oil must be installed before operating. If a chisel is used without oil this co, this could seriously damage the chisel and forfeit any warranty given.

- Before feeding oil, use the provided wrench to remove the oil gauge

- Be careful not to lose the rubber packing attached below the oil gauge. 3) Check the oil level once daily, confirming that oil is filled.

- After feeding oil, securely clamp the oil gauge.

Inspection

- Inspecting dull bits can cause motor malfunction and degraded efficiency. Always replace dull bits with new ones without delay when abrasion is noted.

- Inspecting the mounting screws. Regularly inspect all mounting screws and ensure that they are properly tightened. Should any of the screws be loose, retighten them immediately. Failure to do so could result in serious injury.

- Maintenance of the motor. The motor unit winding is the very “heart” of the power tool. Exercise due care to ensure the winding does not become damaged and/or wet with oil or water.

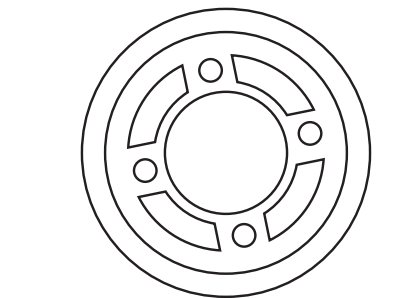

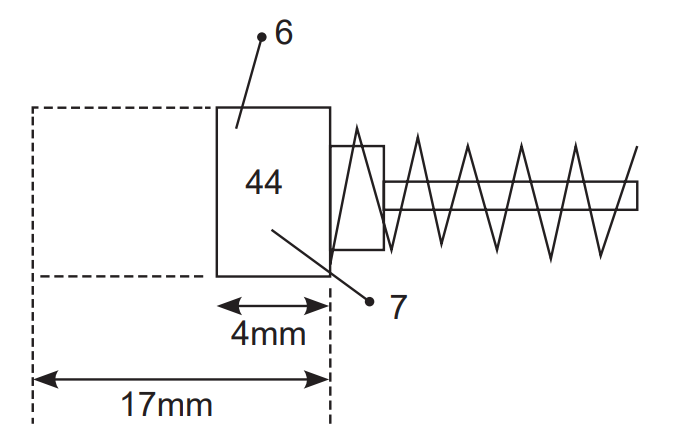

- Inspecting the carbon brushes. The motor employs carbon brushes that are consumable parts; since an

excessively worn carbon brush could result in motor trouble, replace the carbon brushes. Wear limiter (6), No of c, carbon brushes (7).

Always keep carbon brushes clean and ensure that they slide freely within the brush holders.

Replacement Step

The carbon brush can be removed by removing the cap cover (9), cap rubber and bru,, sh shroud in that order at the interior. To replace the carbonush, reverse the order of removal.

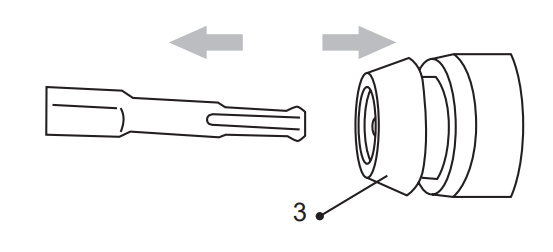

Installing Bits

Never hold the chuck body with one hand and use the chisel power to the chisel body to loosen or tighten bits. You may severely injure your hand.

- The hex bit is secure.

- Oil level is full.

- Select to action you want to do before you engage in the proposed operation

- All safety apparel. Safety Glasses Safety Shoes. Safety Gloves.

- Failure to adhere to these safety rules can greatly increase the chances of injury.

Environmental Instructions

- Dispose of cardboard packaging and polyethylene (PE) bags in the appropriate containers for separate collection of municipal waste according to their description.

- If there are batteries in the device, remove them and separately return them to the collection and storage facility. Return the used device to a suitable collection and storage facility, as the hazardous substances in it may pose a threat to health and the environment.

- Waste electrical equipment is waste that contains substances harmful to humans, animals, and the environment.

- These substances can lead to contamination of the soil, water, or air, and through this they can get into the human body and lead to numerous health ailments, such a vision, hearing, and speech disorders; they can also lead to kidney, liver, and heart damage, and cause skin diseases.

- Harmful substances can also have adverse effects on the respiratory and reproductive systems and lead to cancerous changes. Consumption of plants growing on the contaminated soils, and products made from them, may risk the above-mentioned health effects.

- Do not dispose of the device in the municipal waste container!!! Service: If you wish to purchase spare parts or report any complaints, please contact directly with the seller who issued the receipt directly.

Customer Support

- Address: Lyoner Str. 36 60528 Frankfurt am Main

- Tel:+49 69 310 900 66

- Website: www.ronixtools.com

FAQs

Q: Can I adjust the drilling speed?

Indeed. Because of its variable speed trigger, the rotary hammer lets you adjust the RPM based on the drilling size and material. Metals respond better at lower speeds, while masonry responds better to higher speeds.

Q: What is the purpose of the auxiliary handle?

Particularly when drilling harder materials or larger diameters, the auxiliary handle improves accuracy and reduces operator fatigue by offering additional stability and control.

Q: Can I use this rotary hammer for chiseling or demolition?

Indeed. Use the proper flat or pointed chisel and switch to hammer-only mode. To avoid mishaps, keep control and support the workpiece at all times when chiselling.

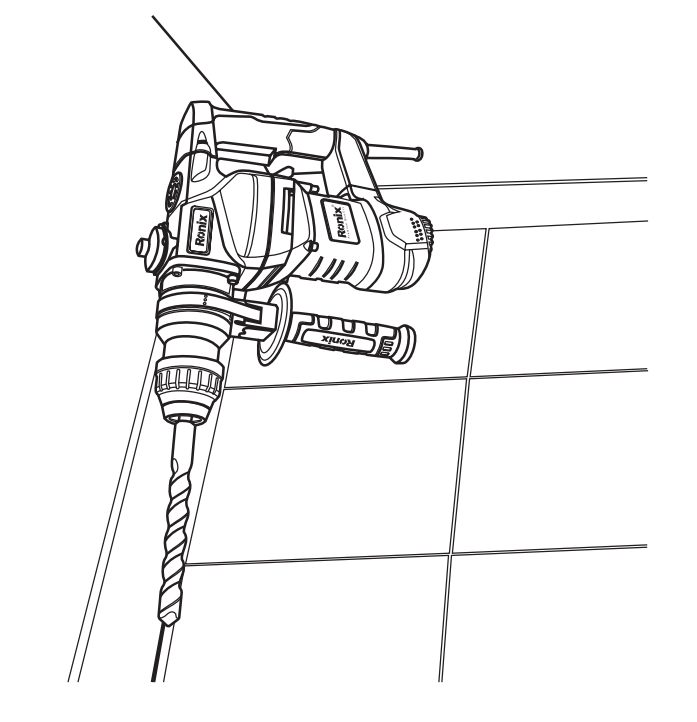

Q: Can I drill into tiles with the Ronix 2732?

Yes, in rotation-only mode with a carbide-tipped bit. To prevent tile cracking, start slowly and apply light pressure.

Q: Does the Ronix 2732 come with a carrying case?

Indeed. For easy storage and transportation, the majority of kits come with an auxiliary handle, depth gauge, sturdy carrying container, and SDS-Plus bits.

Q: Where can I get replacement parts or service?

Authorised Ronix dealers and service centres offer genuine Ronix replacement parts, accessories, and technical support. For assistance, check out the official Ronix website or refer to your warranty card.

Q: Can I operate the Ronix 2732 with one hand?

No. Always utilise both handles for precision and safety because of its great power and torque. Bit breakage or injuries may result with onefromfromded operation.

2 Comments

Pingback: Ronix 2510 10mm Electric Screw Driver | Safety & User Guide

Pingback: Ronix RA-1701 45 BPM Air Hammer Kit Manual | Full Setup Guide