Makita TD004G Cordless Impact Driver

Safety Instructions

- When using the Makita TD004G Cordless Impact Driver, always be sure you have firm footing before starting work.2. Ensure no one is below you when operating the Makita TD004G Cordless Impact Driver in high locations.

3. Hold the tool firmly at all times and wear proper ear protectors when using the Makita TD004G Cordless Impact Driver.

4. Do not touch the bit or the workpiece immediately after operation — they may be extremely hot and could burn your skin.

5. Keep your hands away from all rotating parts of the Makita TD004G Cordless Impact Driver.

6. Use auxiliary handles if supplied with the tool; loss of control can cause personal injury.

7. Do not disassemble or tamper with the battery cartridge of the Makita TD004G Cordless Impact Driver, as it may result in fire, excessive heat, or explosion.

8. If operating time of the Makita TD004G Cordless Impact Driver becomes excessively shorter, stop operation immediately to prevent overheating, possible burns, or explosion.

9. Do not short the battery cartridge or touch the terminals with any conductive material.

10. Avoid storing the battery cartridge of the Makita TD004G Cordless Impact Driver with metal objects such as nails, coins, or keys.

11. Do not expose the battery cartridge to water or rain — a short circuit can cause overheating, burns, or damage to the Makita TD004G Cordless Impact Driver.

Specifications

| Model: | TD004G | |

| Fastening capacities | Machine screw | M4 – M8 |

| Standard bolt | M5 – M20 | |

| High tensile bolt | M5 – M14 | |

| No load speed (RPM) | 4 (Max impact mode) | 0 – 3,900 min-1 |

| 3 (Hard impact mode) | 0 – 3,000 min-1 | |

| 2 (Medium impact mode) | 0 – 2,100 min-1 | |

| 1 (Soft impact mode) | 0 – 1,200 min-1 | |

| T mode | 0 – 2,400 min-1 | |

| Impacts per minute | 4 (Max impact mode) | 0 – 3,900 min-1 |

| 3 (Hard impact mode) | 0 – 3,600 min-1 | |

| 2 (Medium impact mode) | 0 – 3,100 min-1 | |

| 1 (Soft impact mode) | 0 – 1,900 min-1 | |

| T mode | – | |

| Rated voltage | D.C. 36 V – 40 V max | |

| Overall length | 136 mm | |

| Net weight | 1.8 – 3.1 kg |

Applicable Battery Cartridge and Charger

| Battery cartridge | BL4020* / BL4025* / BL4040* / BL4040F* / BL4050F / BL4080F Recommended battery |

| Charger | DC40RA / DC40RB / DC40RC / DC40WA / BCC01 / BCC02 |

Intended use

The tool is intended for screw driving in wood, metal, and plastic.

Noise

The typical A-weighted noise level determined according to EN62841-2-2:

- Sound pressure level (LpA): 100 dB (A)

- Sound power level (LWA) 108 dB (A)

- Uncertainty (K) : 3 dB (A)

Vibration

The vibration total value (tri-axial vector sum) is determined according to EN62841-2-2:

- Work mode: impact tightening of fasteners to the maximum capacity of the tool

- Vibration emission (ah) 23.5 m/s2

- Uncertainty (K):1.5 m/s2

Functional Description

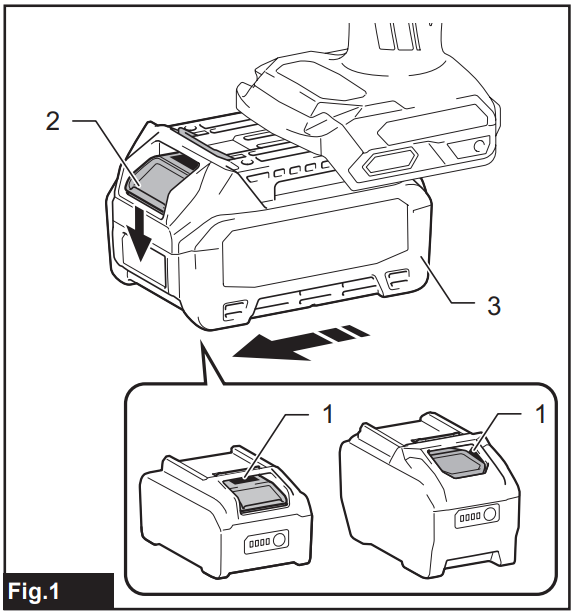

To install the battery cartridge, align the tongue on the battery cartridge with the groove in the housing and slip it into place. Insert it all the way until it locks in place with a little click. If you can see the red indicator as shown in the figure, it is not locked completely. To remove the battery cartridge, slide it from the tool while pressing the button on the front of the cartridge. ► Fig.1: 1. Red indicator 2. Button 3. Battery cartridge

Indicating the remaining battery capacity

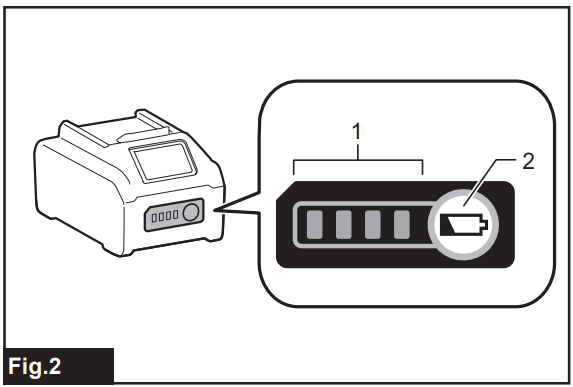

Press the check button on the battery cartridge to indicate the remaining battery capacity. The indicator lamps light up for a few seconds. ► Fig.2: 1. Indicator lamps 2. Check button

Tool/battery Protection System

The tool is equipped with a tool/battery protection system. This system automatically cuts off power to the

motor to extend tool and battery life. The tool will automatically stop during operation if the tool or battery is placed under one of the following conditions:

Overload Protection

When the battery is operated in a manner that causes it to draw an abnormally high current, the tool automatically stops without any indication. In this situation, turn the tool off and stop the application that caused the tool to become overloaded. Then turn the tool on to restart.

Overdischarge Protection

When the battery capacity is not enough, the tool stops automatically. In this case, remove the battery from the tool and charge the battery.

Protections against other The protection system is also designed for other causes that could damage the tool and allows the tool to stop automatically. Take all the following steps to clear the causes when the tool has been brought to a temporary halt or stops in operation.

- Make sure that all switch(es) is/are in the off position, and then turn the tool on again to restart.

- Charge the battery(ies) or replace it/them with h recharged battery(ies).

- Let the tool and battery(ies) cool down.

If no improvement can be found by restoring the protection system, then contact your local Makita Service Center.

Switch Action

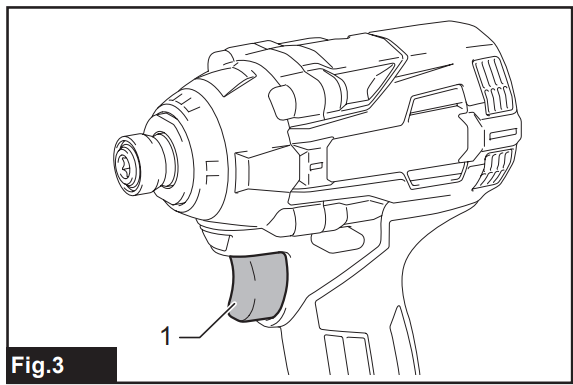

To start the tool, simply pull the switch trigger. The speed is increased by increasing pressure on the switch trigger. Release the switch trigger to stop. ► Fig.3: 1. Switch trigger

Reversing Switch Action

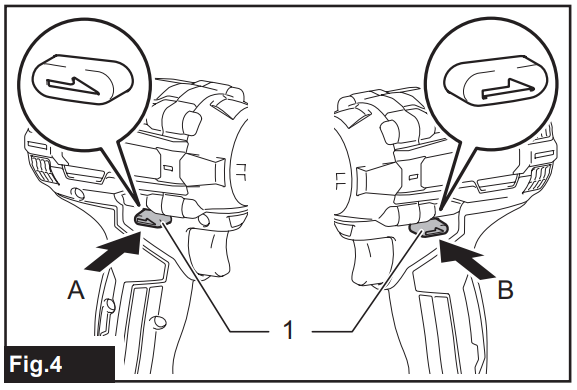

This tool has a reversing switch to change the direction of rotation. Depress the reversing switch lever from the A side for clockwise rotation or from the B side for counterclockwise rotation. When the reversing switch lever is in the neutral position, the switch trigger cannot be pulled. ► Fig.4: 1. Reversing switch lever

Electric Brake

This tool is equipped with an electric brake. If the tool consistently fails to quickly stop after the switch trigger is released, have the tool serviced at a Makita service center.

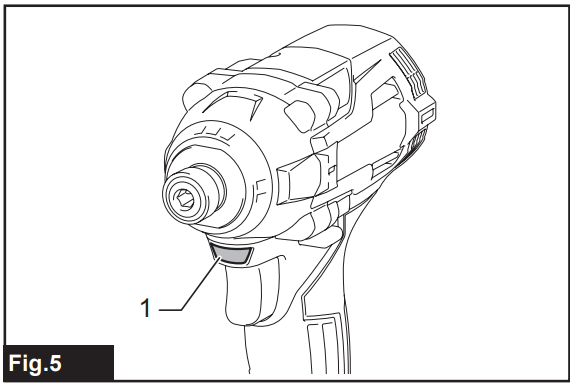

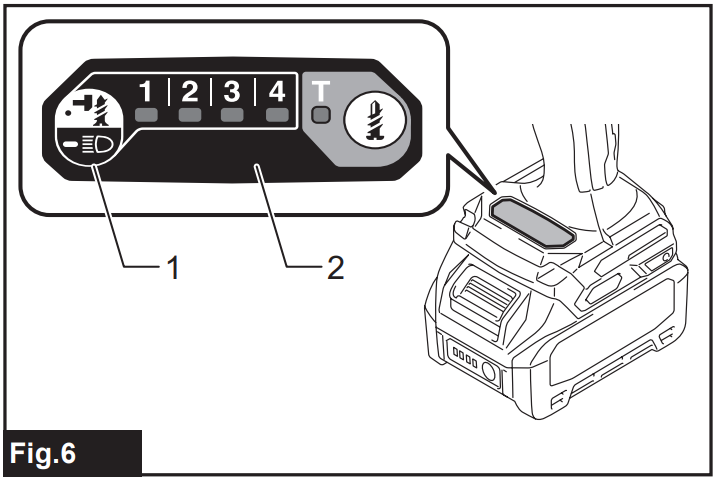

Lighting up the Front Lamp

Fig.5: 1. Front lamp

Pull the switch trigger to turn on the front lamp. To turn off, release the switch trigger. The front lamp goes out approximately 10 seconds after releasing the switch trigger. To disable the front lamp, turn off the lamp status. To turn off the lamp status, first pull and release the switch trigger. Within 10 seconds after releasing the switch trigger, press and hold the button for a few seconds. When the lamp status is off, the front lamp will not turn on even if the trigger is pulled. To turn on the lamp status again, press and hold the button for a few seconds. ► Fig.6: 1. Button 2. Switch panel

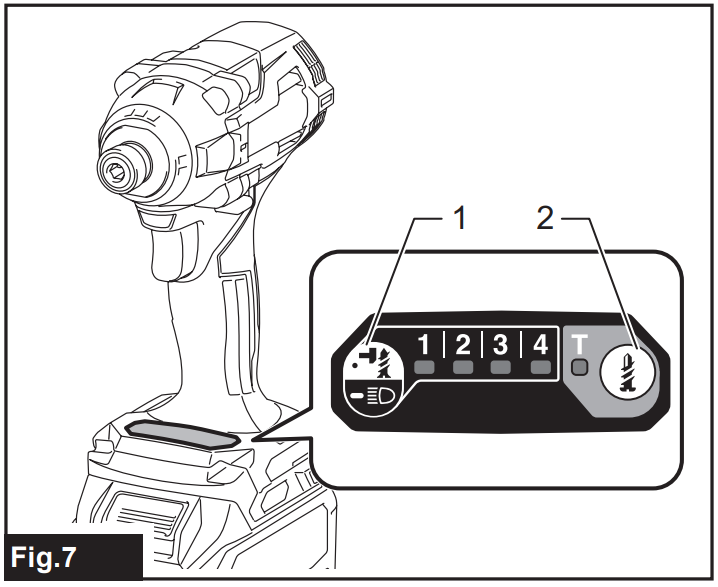

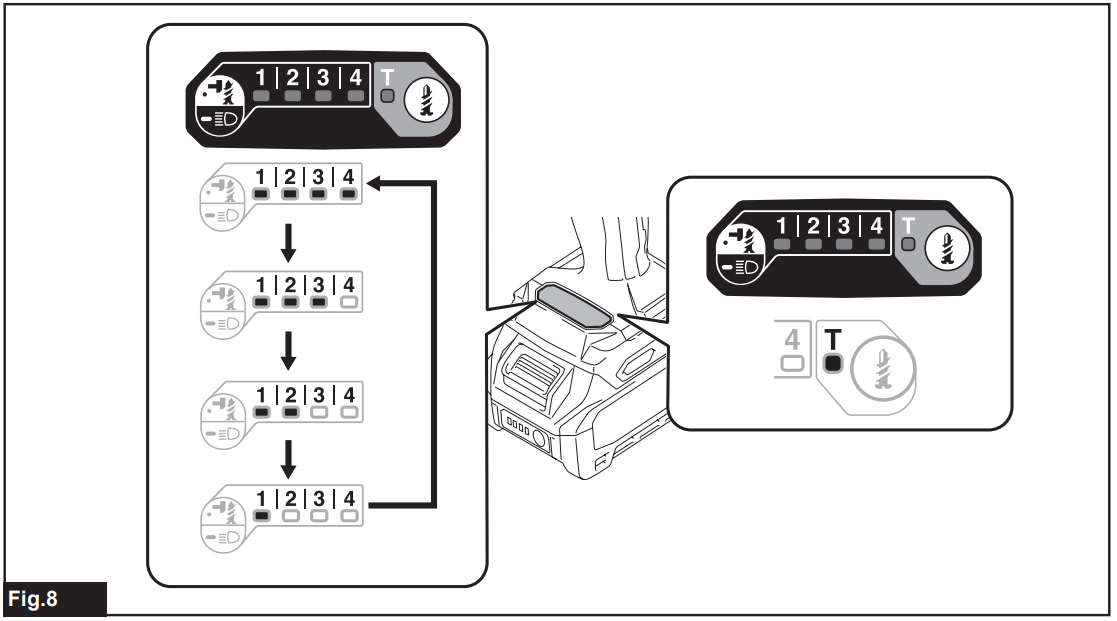

Changing the Impact Force

You can change the impact force in five steps: 4 (max), 3 (hard), 2 (medium), 1 (soft), and T mode.

This allows a tightening suitable for the work. “T” is a special mode for fastening self-drilling screws. This mode helps to prevent the screws from over-tightening. It also accomplishes quick operation and a good finish at the same time. The tool drives a screw with high-speed rotation and stops soon after the tool starts to impact. The level of impact force changes every time you press the button or button. You can change the impact force within approximately one minute after releasing the switch trigger.

Changing the Application Mode

What’s the application mode?

The application mode is the variation of the driving rotation and impact, which are already preset in the tool. By choosing a suitable application mode depending on the work, you can accomplish quicker work and/or a more beautiful finish.

This tool features the following application modes:

Impact force

- 4 (Max)

- 3 (Hard)

- 2 (Medium)

- 1 (Soft)

- T mode

The application mode can be changed by the button or button. ► Fig.7: 1. Button 2. Button

| Application mode (Impact force grade displayed on panel) | Maximum blows | Purpose | Example of application |

| 4 (Max) | 3,900 min-1 (/min) | Tightening with the maximum force and speed. | Driving screwsintoo the underwork materials, tightening long screws or bolts. |

| 3 (Hard) | 3,600 min-1 (/min) | Tightening with less force and speed than Max mode (easier to control than Max mode). | Driving screws into underworked materials, tightening bolts. |

| 2 (Medium) | 3,100 min-1 (/min) | Tightening when a good finish is needed. | Driving screws into finishing boards o oards. |

| 1 (Soft) | 1,900 min-1 (/min) | Tightening with less force to avoid screw thread breakage. | Tightening sash screws or small screws such as M6. |

| T mode * | (The tool stops rotating soon after impact starts.) | Driving self-drilling screws into a thin metal plate with a good finish. | Tightening self-drilling screws. |

The lamp is on. When the tool rotates counterclockwise, the impact per minute is the same as in 4 (max) mode, 3,900 min-1 (/ min).

Assembly

Installing or removing a driver bit/socket bit

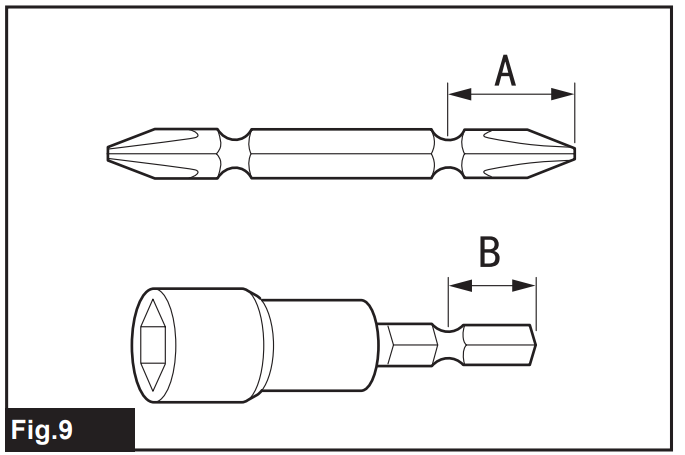

Use only the driver bit/socket bit that has the inserting portions shown in the figure. Do not use any other driver bit/ socket bit.

For a tool with a shallow driver bit hole

| A=12mm B=9mm | Use only these types of driver bits. Follow procedure 1. (Note) Bit-piece is not necessary. |

For a tool with a deep driver bit hole

| A=17mm B=14mm | To install these types of driver bits, follow procedure 1. |

| A=12mm B=9mm | To install these types of driver bits, follow procedure 2. (Note) Bit-piece is necessary for installing the bit. |

Procedure 1

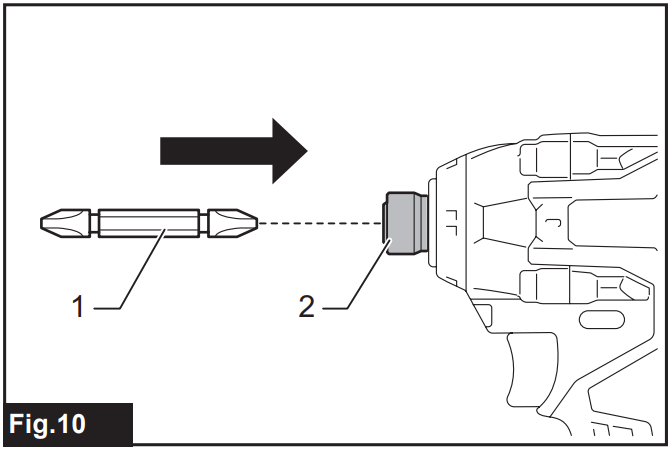

For a tool with a one-touch type sleeve, to install the driver bit, insert the driver bit into the sleeve as far as it will go.

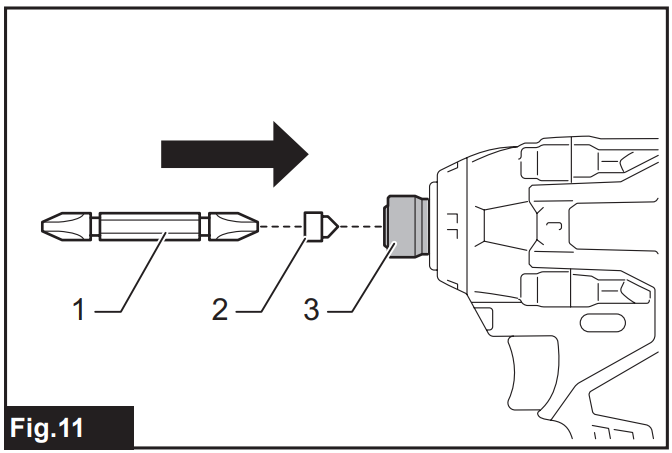

Procedure 2

In addition to Procedure 1, insert the bit-piece into the sleeve with its pointed end facing in.

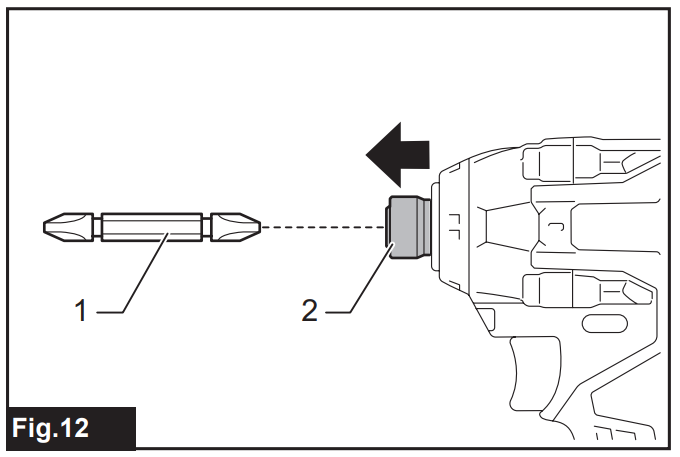

To remove the driver bit, pull the sleeve in the direction of the arrow and pull the driver bit out.

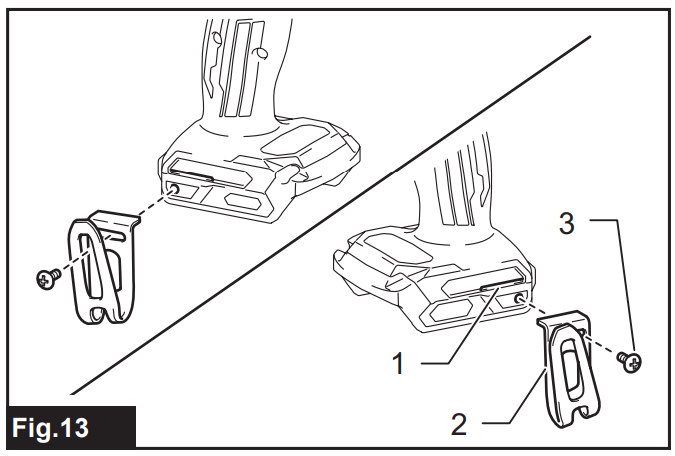

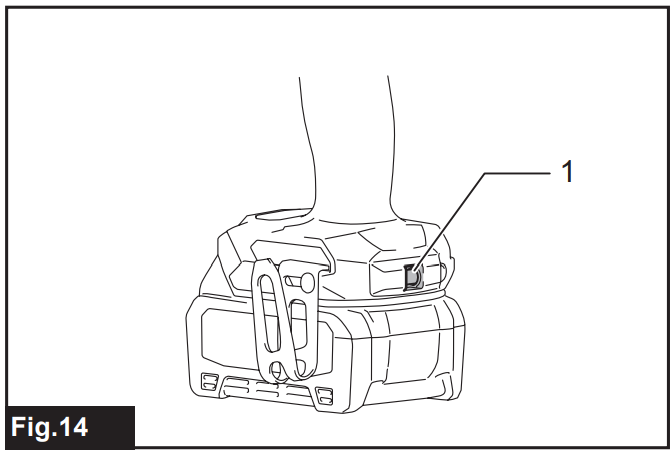

Installing hook

The hook is convenient for temporarily hanging the tool. This can be installed on either side of the tool. To install the hook, insert it into a groove in the tool housing on either side and then secure it with a screw. To remove, loosen the screw and then take it out.

Using hole

Use the hanging hole at the bottom rear of the tool to hang the tool on a wall using a hanging cord or similar strings.

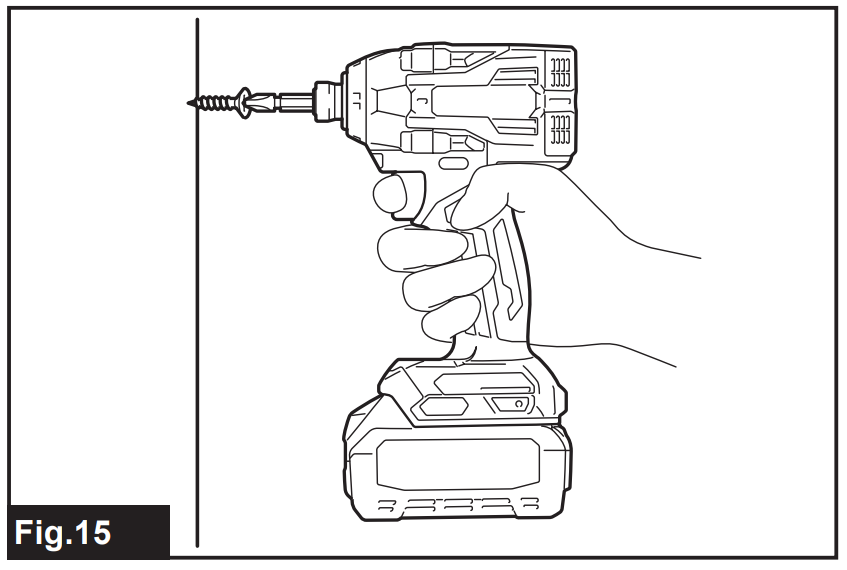

Operation

The proper fastening torque may differ depending upon the kind or size of the screw/bolt, the material of the workpiece to be fastened, etc.

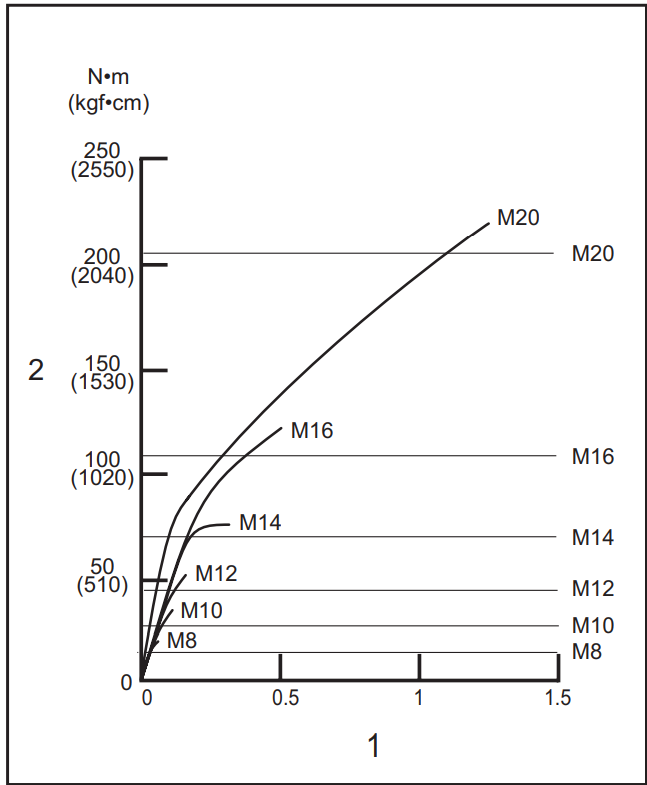

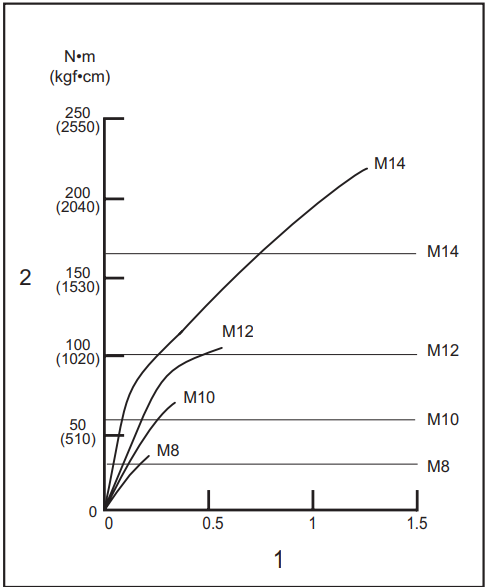

The relation between fastening torque and fastening time for a standard bolt (when the impact force is 4)

1. Fastening time (seconds) 2. Fastening torque The relation between fastening torque and fastening time for a high tensile bolt (when the impact force is 4)

The fastening torque is affected by a wide variety of factors, including the following. After fastening, always check the torque with a torque wrench.

- When the battery cartridge is discharged almost completely, the voltage will drop, and the fastening torque will be reduced.

- Driver bit or socket bit. Failure to use the correct size driver bit or socket bit will cause a reduction in the fastening torque.

- Bolt

- Even though the torque coefficient and the class of bolt are the same, the proper fastening torque will differ according to the diameter of the bolt.

- Even though the diameters of bolts are the same, the proper fastening torque will differ according to the torque coefficient, the class of bolt, and the bolt length.

- The manner of holding the tool or the material of the driving position to be fastened will affect the torque.

- Operating the tool at low speed will cause a reduction in the fastening torque.

Optional Accessories

If you need any assistance for more details regarding these accessories, ask your local Makita Service.

Center.

- Driver bits

- Socket bits

- Bit-piece

- Hook

- Tool hanger

- Plastic carrying case

- Makita genuine battery and charger

Customer Service

- Website: https://www.makitauk.com/

- Ph: 1-800-462-5482

FAQs

Q: What is the Makita TD004G?

With its small size, brushless motor, and high torque output for both professional and do-it-yourself applications, the TD004G is a cordless impact driver made to drive screws and bolts fast and effectively.

Q: What battery type does it use?

It is compatible with other Makita 12V tools and runs on Makita 12V max Lithium-Ion batteries.

Q: Is the impact driver brushless?

Indeed. With its brushless motor, the TD004G offers increased efficiency, reduced maintenance, and a longer runtime.

Q: What is the maximum torque of this impact driver?

With a torque of up to 125 Nm, the TD004G is appropriate for medium-to heavy-duty fastening applications.

Q: What is the chuck size?

It is compatible with regular 1/4″ hex shank driver bits and features a 1/4″ hex chuck.

Q: Can it be used for drilling?

It is mostly used as an impact driver to drive bolts and screws. It is not designed for heavy-duty drilling, although it can drill soft materials with hex-shank bits.

Q: Does it have a reverse function?

Indeed. A forward/reverse switch on the TD004G makes it simple to remove bits or adjust mismatched screws. Indeed. A forward/reverse switch on the TD004G makes it simple to remove bits or adjust mismatched screws.

Q: Is it lightweight and compact?

Indeed. With the battery included, the tool weighs just 1.1 kg (2.4 lbs), which makes it convenient to use in confined areas or overhead applications.