Ronix RA-1701 45 BPM Air Hammer Kit

Safety Instructions

- Always wear safety goggles, a face mask, or respiratory equipment.

- Always ensure the machine is switched off before connecting to the air supply.

- Always keep your air tool clean and lubricated.

- Daily lubrication is essential to avoid internal corrosion and possible failure.

- Do not wear watches, rings, bracelets, or loose clothing when using air tools.

- Using onllightweightht coil hoses from a tool to the wall or compressor coupling.

- Also, this creates excessive wear on moving parts and possible failure.

- Always ensure that the workpiece is firmly secured, leaving both hands free to control the machine.

- Also, correctly and securely fastened before connecting the machine to the air supply.

- Always ensure that the accessories, such as blades, discs, sockets, etc., are rated/designed for use with the machine.

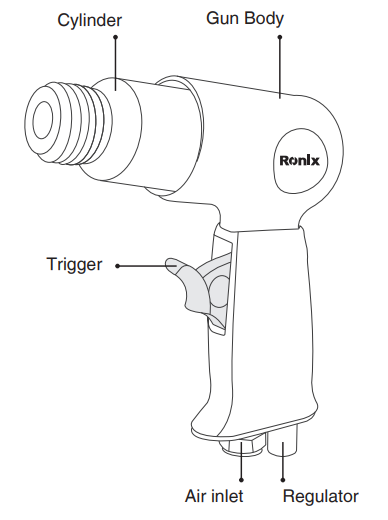

Part List

Description

Hardened steel barrel and piston for less wear and longer life, lightweight aluminum pistol grip housing, front exhaust, 43mm air hammer set includes the chisels (round & hex), a retainer spring, and a quick coupler, ideal for general cutting, chipping,g, and scraping. For heavier demolition or rotary hammer tasks, you can also check the Ronix 2732 1250 W Rotary Hammer Instructions Manual for setup, operation, and safety guidelines.

Air Supply

- Ensure the air valve (or trigger) is in the “off” position before connecting to the air supply.

- You will require an air pressure of 90psi, and an air flow according to the specification.

- Drain the air tank daily. Water in the airline will damage the tool.

- Clean the IR inlet filter weekly.

- Line pressure should be increased to compensate for unusually long air hoses (over 8 meters).

- The hose diameter should be 3/8”.

- Keep hoses away from heat, oil, and sharp edges.

- Check the hoses for wear, and make certain that all connections are secure.

Lubrication

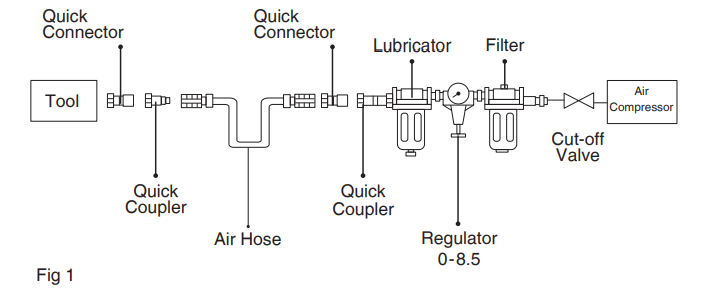

An automatic in-line filter/regulator/lubricator is recommended (Fig.) as it increases tool life and keeps the tool in sustained operation. The in-line lubricator should be regularly checked and filled with air tool oil. Proper adjustment of the in-line lubricator is performed by placing a sheet of paper next to the exhaust ports and holding the throttle open for approximately 30 seconds. The lubricator is properly set when a light stain of oil collects on the paper. Excessive amounts of oil should be avoided.

If it becomes necessary to store the tool for an extended period of time (overnight, weekend, etc.), it should receive a generous amount of lubrication at that time. The tool should be run for approximately 30 seconds to ensure oil has been evenly distributed throughout the tool.

The tool should be stored in a clean and dry environment. It is most important that the tool be properly lubricated by keeping the airline lubricator filled and correctly adjusted. Without proper lubrication, the tool will not work properly, and parts will wear prematurely. Use the proper lubricant in the air line lubricator.

The lubricator should be of low air flow or changing air flow type, and should be kept filled to the correct level. Use only recommended lubricants, specially made for pneumatic applications. Substitutes may harm the rubber compounds in the tools, O-rings, and other rubber parts.

If a filter/regulator/lubricator is not installed on the air system, air-operated tools should be lubricated at least once a day or after 2 hours of work with 2 to 6 drops of oil, depending on the work environment, directly through the male fitting in the tool housing.

Operation

- Connect the tool to the air hose.

- Press the trigger to operate the tool.

- The flow of air may be regulated by adjusting the flow valve at the base of the handle.

- Ensure the air supply is clean and does not exceed 90psi while operating the tool.

- Too high an air pressure and unclean air will shorten the product life due to excessive wear, and may be dangerous, causing damage or personal injury.

- DO NOT use any additional force upon the tool. Allow the tool to free-run for an extended period of time, as this will shorten its life.

Maintainance

Disconnect the tool from the air supply before changing accessories, servicing, or performing maintenance. Replace or repair damaged parts. Use genuine parts only. Non-authorized parts may be dangerous.

- Lubricate the air tool daily with a few drops of air tool oil dripped into the air inlet.

- DO NOT use a worn or damaged tool.

- Loss of power or erratic action may be due to the following:

- Excessive drain on the air line. Moisture or restriction in the air pipe. Incorrect size or type of hose connectors. To check the air supply.

- Grit or gum deposits in the tool may also reduce performance. If your model has an air strainer (located in the area of the air inlet), remove the strainer and clean it.

- When not in use, disconnect from the air supply, clean the tool, and store it in a safe, dry, childproof location.

Specifications

| Model | RA-1701 |

| Power Source | Air |

| Frequency | 4500BPM |

| Piston Stroke | 43mm |

| Air Pressure | 90Psi |

| Air Inlet Size | 1/4″ |

| Noise Level | 96.9db |

| Maximum Bit Holder | 10mm |

| Speed | 4500BPM |

| Material | Aluminum |

| Net Weight | 1Kg |

| Total Weight | 2Kg |

| Supplied in | BMC |

| Include | 1pc oil pot, 4pcs chisels, 1pc spring, 1pc quick coupler 1pc mini oiler |

Troubleshooting

| PROBLEMS | POSSIBLE CAUSES | REMEDIESThe tool |

| l runs at normal speed but loses under load | – Cam clutch worn or sticking due to lack of lubricant. | Lubricating clutch housing. Check for excess clutch oil. Clutch cases need only be half full. Overfilling can cause drag on high-speed clutch parts. A typical oiled/lubricated wrench requires ½ ounce of oil. GREASE LUBRICATED: NOTE: Heat usually indicates insufficient grease in the chamber. Severe operating conditions may require more frequent lubrication. |

| The tool runs slowly. Air flows slightly from the exhaust | – Power regulator in closed position – Air flow blocked by dirt. | Check the air inlet filter for blockage. Pour air tool lubricating oil into the air inlet as per instructions. Operate the tool in short bursts, quickly reversing rotation back and forth where applicable. Repeat above as needed. |

Environmental Instructions

- Dispose of cardboard packaging and polyethylene (PE) bags in the appropriate containers for separate collection of municipal waste according to their description.

- If there are batteries in the device, remove them and separately return them to the collection and storage facility. Return the used device to a suitable collection and storage facility, as the hazardous substances in it may pose a threat to health and the environment.

- Waste electrical equipment is waste that contains substances harmful to humans, animals, and the environment.

- These substances can lead to contamination of the soil, water, or air, and through this they can get into the human body and lead to numerous health ailments, such a vision, hearing, and speech disorders; they can also lead to kidney, liver, and heart damage, and cause skin diseases.

- Harmful substances can also have adverse effects on the respiratory and reproductive systems and lead to cancerous changes. Consumption of plants growing on the contaminated soils, and products made from them, may risk the above-mentioned health effects.

- Do not dispose of the device in the municipal waste container!!! Service: If you wish to purchase spare parts or report any complaints, please contact directly with the seller who issued the receipt directly.

Customer Support

- Address: Lyoner Str. 36 60528 Frankfurt am Main

- Tel:+49 69 310 900 66

- Website: www.ronixtools.com

FAQs

Q: What air pressure does the RA-1701 require?

Use the air hammer at a working pressure of 6.2 bar (90 PSI) for best results. Operating outside of this range could result in decreased efficiency or internal component damage.

Q: What size air compressor should I use with this tool?

A smaller compressor could result in irregular operation or frequent reductions in air pressure.

Q: What air inlet size does the air hammer use?

Most air hoses and fast couplers used in workshop installations are compatible with the RA-1701’s standard 1/4-inch NPT air inlet.

Q: Can I use the RA-1701 for concrete or masonry work?

Use an electric or pneumatic demolition hammer designed specifically for concrete or stone surfaces.

Q: Can I use this tool with other brands of chisels?

Yes, provided that the chisels are of the normal 10 mm (0.401-inch) shank size, which is what the Ronix RA-1701 is compatible with.

Q: Where can I get replacement parts or service?

Authorised Ronix dealers and service centres offer authentic Ronix replacement parts and assistance. To find the closest support contact, visit the official Ronix website or consult your warranty card.

1 Comment

Pingback: Ronix 4110 600 W Electric Jig Saw | User Manual & Safety Guide