![]()

Clarke CPS160 160 MM Plunge Saw

Introduction

Thank you for purchasing this CLARKE 160 mm Plunge Saw. Read this manual fully before you use this product and follow the instructions carefully. In doing so, you will ensure the safety of yourself and that of others around you, and you can look forward to your purchase giving you long and satisfactory service.

Safety Instructions

- Keep the work area clean and well-lit. Cluttered and dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks, which may ignite the dust or fumes.

- Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

- Power tool plugs must match the outlet. Never modify the plug in any way. Do not use adaptor plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce the risk of electric shock.

- Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

- Do not abuse the cable. Never use it for carrying, pulling, or unplugging the power tool. Keep the cable away from heat, oil, sharp edges, or moving parts. Damaged or entangled cables increase the risk of electric shock.

- When operating a power tool outdoors, use an extension cable suitable for outdoor use. Use of a cable suitable for outdoor use reduces the risk of electric shock.

- If operating the power tool in a damp location is unavoidable, use a residual current device (RCD) protected supply.

- Remove any wrench before turning the power tool on. A wrench left attached to a rotating part may result in personal injury.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

- Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing, and gloves away from moving parts. Loose clothes, jewellery, or long hair can be caught in moving parts.

Cartoon Content

If any parts are missing or damaged, please contact the Clarke dealer where you purchased the tool.

- 1 x Plunge Saw

- 1 x Guide Rail Assembly (2 halves and a joining bar)

- 1 x TCT Blade – 160 mm Ø x 20 mm (bore) x 2.4 mm (thickness).

- 1 x Tilt protection clamp (polymer)

- 1 x Tilt protection clamp nut

Specifications

- Model Number CPS160

- Rated Voltage 230V~50Hz

- No Load Speed 5500 RPM

- Maximum Depth of Cut 55 mm @ 90o – 41 mm @ 45o

- Blade Dimensions Diameter – 160 mm Bore – 20 mm Blade Thickness – 2.4 mm

- Length of Track 2 pieces 700 mm each

- Sound Pressure Level LpA 95 dB(A)

- Sound Power Level LWA 106 dB(A)

- Uncertainty Factor (K) 3 dB(A)

- Weight 7.4 kg

- Vibration (main handle) 5.72 m/s2 Uncertainty Factor 1.5

- Dimensions (L x W x H) 340 x 235 x 260 mm

Use & Care

- Do not force the power tool. Use the correct accessories for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

- Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

- Disconnect the plug from the power source before changing accessories or storing power tools. Such preventive safety measures reduce the risk of accidentally starting the power tool.

- Store idle tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate it. Power tools are dangerous in the hands of untrained users.

- Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

- Use the power tool and accessories these instructions and in the manner intended, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from the intended ones could result in a hazardous situation.

- The performance of this tool may vary, depending upon variations in line voltage. Extension cable usage may also affect performance.

- Have your power tool serviced by qualified service personnel using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

CIRCULAR SAW SAFETY WARNINGS

CIRCULAR SAW – CUTTING PROCEDURES

- a. Keep your hands away from the cutting area and the blade. Keep your second hand on the auxiliary handle or motor housing. If both hands are holding the saw, they cannot be cut by the blade.

- b. Do not reach underneath the workpiece. The guard cannot protect you from the blade below the workpiece.

- c. Adjust the cutting depth to the thickness of the workpiece. Less than a full tooth of the blade teeth should be visible below the workpiece.

- d. Never hold the piece being cut in your hands or across your leg. Secure the workpiece to a stable platform. It is important to support the work properly to minimise body exposure, blade binding, or loss of control.

- e. Hold the power tool by the insulated gripping surfac when performing an operation where the cutting tool may contact hidden wiring or its own. Contact with a “live” wire will also make exposed metal parts of the power tool “live” and could give the operator an electric shock.

- f. When ripping, always use a rip fence or straight edge guide. This improves the accuracy of the cut and reduces the chance of blade binding

- g. Always use blades with the correct size and shape of arbor holes. Blades that do not match the mounting hardware of the saw will run eccentrically, causing loss of control.

- h. Never use damaged or incorrect blade washers or bolts. The blade washers and bolt were specially designed for your saw, for optimum performance and safety of operation.

Riving Knive Function

- Use the appropriate saw blade for the riving knife. For the riving knife to function, the body of the blade must be thinner than the riving knife, and the cutting width of the blade must be wider than the thickness of the riving knife.

- Adjust the riving knife as described in this instruction manual. Incorrect spacing, positioning, and alignment can make the riving knife ineffective in preventing kickback.

- For the riving knife to work, it must be engaged in the workpiece. The riving knife is ineffective in preventing kickback during short cuts.

- Do not operate the saw if the riving knife is bent. Even a light interference can slow the closing rate of a guard.

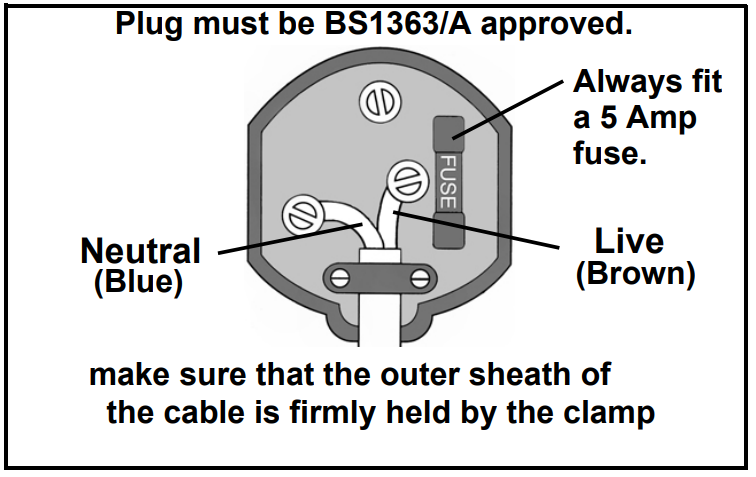

Electrical Connection

If the colours of the wires in the power cable do not correspond with the markings on the terminals of your plug, proceed as follows.

- Connect the blue wire to the terminal that is marked N.

- Connect the brown wire to the terminal that is marked L.

We recommend that this plunge saw is connected to the mains supply via a Residual Current Device (RCD). If in doubt, consult a qualified electrician.

Adjusments

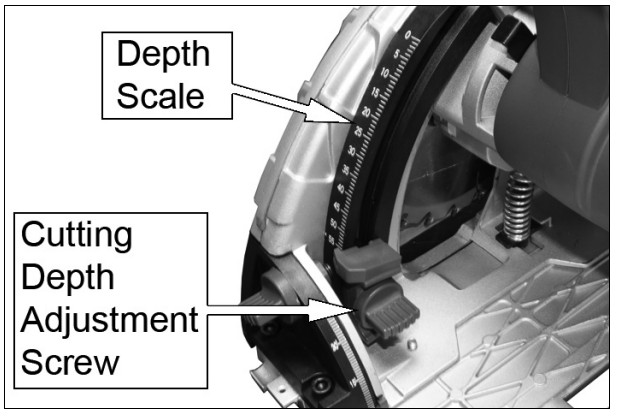

The cutting depth can be adjusted from 0 to 55 mm.

- Loosen the cutting depth adjustment screw.

- Set the required depth using the scale.

- Retighten the screw.

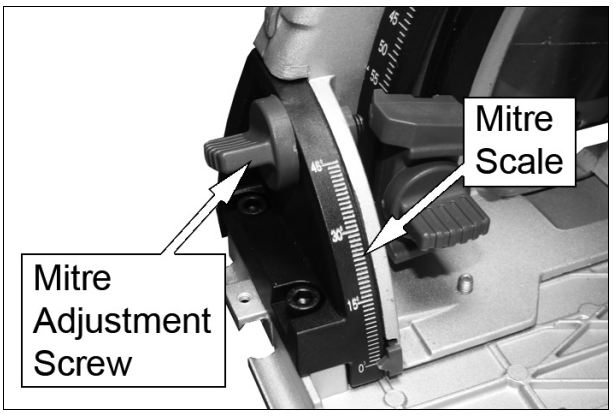

Metre Adjusment

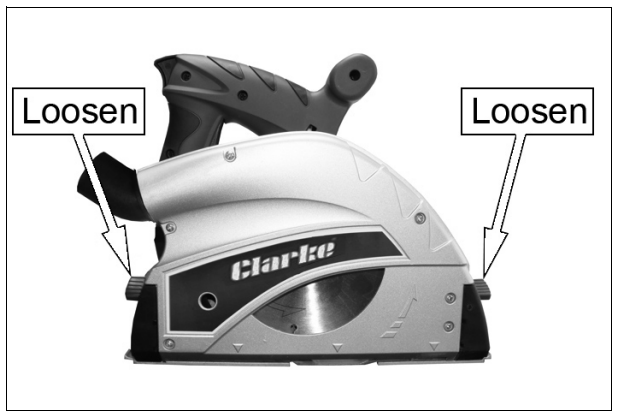

- Loosen the mitre adjustment screws on both sides.

- Set the desired mitre angle.

- Retighten both mitre adjustment screws to lock the base at the required angle.

Operation

- Secure the workpiece so that it cannot be moved while sawing.

- Only move the saw in the forward direction.

- When using a guide rail, it must be fastened with suitable clamps.

- Make sure the power cable is kept well clear of the blade.

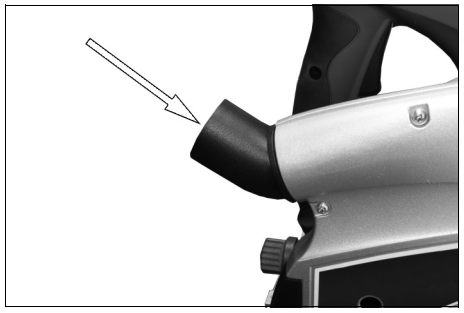

- Internal diameter is 34 mm

- External diameter is 38 mm

Hand Position

For your safety, grip the saw as shown in this picture, with one hand on the main handle and the other on the front handle.

Switching ON/OFF

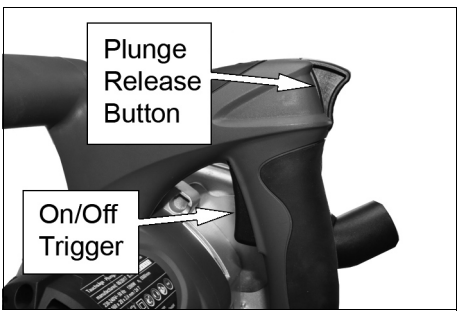

The on/off trigger is fitted with a safety button, which prevents the saw from being started accidentally. To start the saw:

- Slide the plunge release button upward and squeeze Clarke CPS160 160 MM Plunge Saw the on/off trigger to start the saw.

- Release the on/off trigger. And allow the saw to spring up when the saw cutting is complete.

- The blade will continue to rotate for several seconds after the trigger has been released

Sawing

- Place the front part of the plunge saw onto the workpiece.

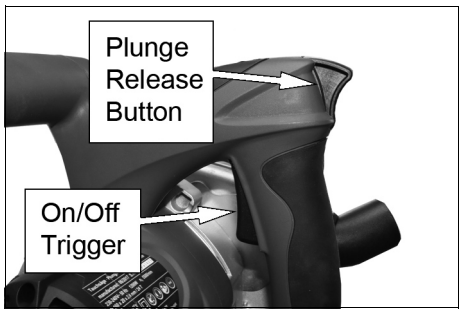

- Slide the plunge release button forward and squeeze the on/off trigger to start the saw.

- Push the saw down until you reach the set cutting depth.

- Push the saw forward along the cut line.

- Release the on/off trigger. And allow the saw to spring up when the saw cutting is complete.

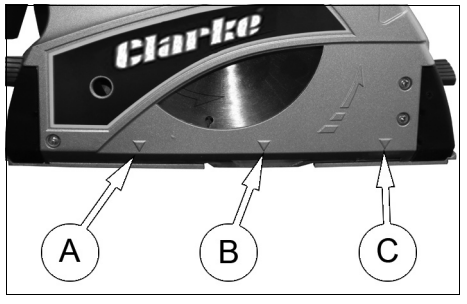

Plunge Cuts

- Mark the beginning and end of the cut on the workpiece, and place the plunge saw onto the workpiece.

- Align the cutting indicator (A) with the start of the plunge-cut.

- Slide the plunge release button upward and squeeze the Clarke CPS160 160 MM Plunge Saw on/off trigger to start the saw.

- Push the saw down until you reach the set cutting depth.

- Move the saw forward until the front cutting indicator (C) reaches the end of the plunge cut.

- Release the on/off trigger. And allow the saw to spring up when the saw cutting is complete.

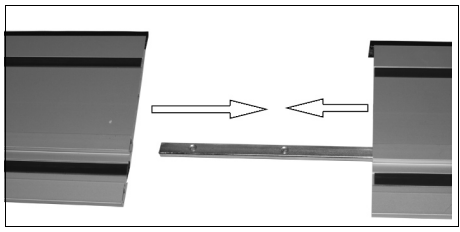

Guide Rails

- Insert the joining bar halfway into one of the rails and secure using 2 of the set screws on the joining bar.

- Slide the second rail over the other half of the joining bar until the rails are touching and secure using the remaining 2 set screws on the joining bar

Using the Rails

- Place the plunge saw onto the guide rails as Clarke CPS160 160 MM Plunge Saw shown.

- Slide the plunge release button upward and squeeze the on/off trigger to start the saw.

- Push the saw down until you reach the set cutting depth.

- Push the saw forward to cut

- Release the on/off trigger and allow the saw to spring up when the saw cutting is complete.

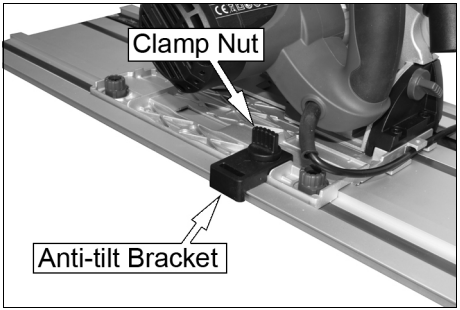

- If you are performing a mitre cut using the rail, you may need to fit the anti-tilt bracket as shown using the clamp nut supplied.

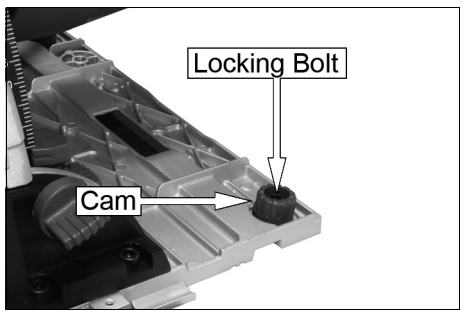

Rail Adjustment

If you notice that the saw is loose on the rail,

- Use the hex key supplied to loosen the locking bolt at each end.

- Adjust the cam until the saw slides easily but without any play left or right.

- Retighten the locking bolt.

Maintainance

- Slide the plunge release button upward and set the Clarke CPS160 160 MM Plunge Saw blade depth to 25 mm.

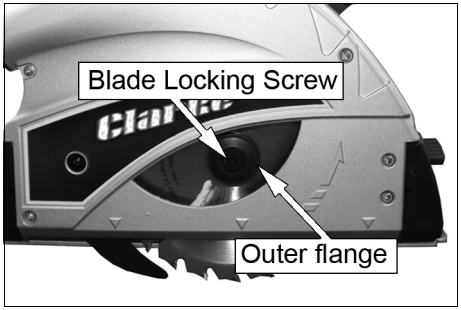

- Insert the hex key supplied into the blade locking screw.

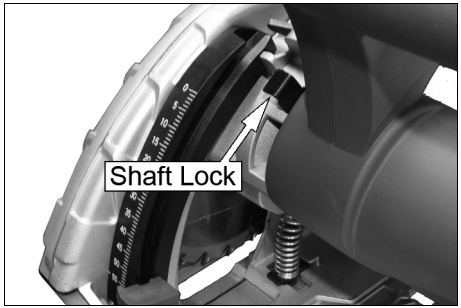

- Press the shaft lock and rotate the saw blade by hand until the lock clicks into place.

- Keep holding the shaft lock down and turn the blade locking screw counterclockwise.

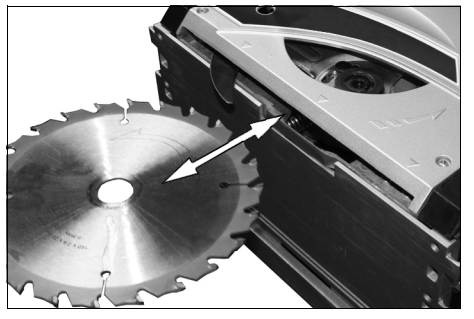

- Remove the outer flange and then the saw blade.

- Insert the new blade and replace the flange.

- Tighten the saw blade locking screw whilst holding Clarke CPS160 160 MM Plunge Saw down the shaft lock.

- Release the shaft lock and set the plunge saw depth to its original position.

- Make sure that all adjustment keys are removed before use.

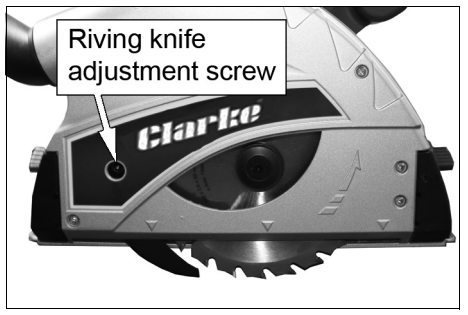

Riving Knive

- Slide the plunge release button upward and set the blade depth to 25 mm.At this depth, you should be able to see the riving knife adjustment screw through the hole in the blade guard.

- Insert the hex key supplied and loosen the riving Clarke CPS160 160 MM Plunge Saw knife adjustment screw.

- Adjust the riving knife so that it is equally spaced around the blade.

- Tighten the riving knife adjustment screw and set the plunge saw depth to its original position.

- Make sure that the hex key is removed before use.

Guarantee

This product is guaranteed against faulty manufacture for 12 months from the date of purchase. Please keep your receipt, which will be required as proof of purchase. This guarantee is invalid if the product is found to have been abused or tampered with in any way, or not used for the purpose for which it was intended. Faulty goods should be returned to their place of purchase; no product can be returned to us without prior permission. This guarantee does not affect your statutory rights.

Customer Service

- Tel: 0208 988 7400

- Website: parts@clarkeinternational.com

- Visit: service@clarkeinternational.com

FAQs

What materials can I cut with the Clarke CPS160 plunge saw?

With the right blade, the CPS160 can cut non-ferrous metals like aluminium as well as wood, plywood, MDF, laminates, and plastics.

How do I change the saw blade safely?

Unplug the saw first. After securing the blade with the blade lock button, unscrew the arbour nut using the included wrench.

What is the maximum cutting depth of the CPS160?

At 90 degrees, the maximum cutting depth is roughly 55 mm. You can change the depth to meet your cutting needs.

How do I adjust the bevel angle?

At 90 degrees, the maximum cutting depth is roughly 55 mm. You can change the depth to meet your cutting needs.

Can I use the plunge saw for precise plunge cuts?

Indeed, you can begin cutting in the heart of a material with controlled depth and less splintering thanks to the CPS160’s precise plunge cutting mechanism.

Does the CPS160 have dust extraction capability?

Indeed, it has a dust port that works with regular hoover hoses to keep your work area tidy while in use.

How do I ensure straight and accurate cuts?

For straight cuts, guide the saw using a guide rail or straight edge fastened to the workpiece.

What safety features are included with this plunge saw?

It has an electric brake for rapid blade stopping, a safety switch to avoid unintentional starts, and a blade guard that retracts during cutting.