Clarke CWL435 17-Inch Wood Lathe

Introduction

Thank you for purchasing this CLARKE 17” Wood Lathe. Before attempting to operate the machine, it is essential that you read this manual thoroughly and carefully follow all instructions given. In doing so, you will ensure the safety of yourself and that of others around you, and you can also look forward to the product giving you long and satisfactory service.

Safety Instructions

- DO NOT use adapter plugs with earthed (grounded) power tools.

- Unmodified plugs and matching outlets will reduce the risk of electric shock.

- This machine is designed for indoor environments and must not be used for other purposes.

- DO NOT expose power tools to rain or wet conditions.

- Water entering a power tool will increase the risk of electric shock.

- DO NOT force the machine. Use the correct power tool for your application.

- It will do a better and safer job at the rate for which it was designed.

- DO NOT use the power tool if the switch does not turn it on and off.

- Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

- These measures will reduce the risk of the power tool starting accidentally.

- Maintain power tools in top condition. Keep tools/ machines clean for the best and safest performance.

- Check for misalignment or binding of moving parts, broken parts, or any condition that may affect the power tool’s operation.

- If damaged, have the power tool repaired before use.

- Many accidents are caused by poorly maintained power tools.

- Use recommended accessories. The use of improper accessories could be hazardous.

- Machine cleanliness. DO NOT allow the ventilation slots in the machine to become blocked with dust.

- When necessary, have your power tools serviced or repaired by a qualified person using identical replacement parts. This will ensure that the safety of the power tool is maintained.

Symbols

The following safety symbols may be found on the machine.

- Fully read this manual and the safety instructions before use

- Ear protection should be worn

- Indoor use only

- Eye protection should be worn.

- A dust mask should be worn

Electrical Connection

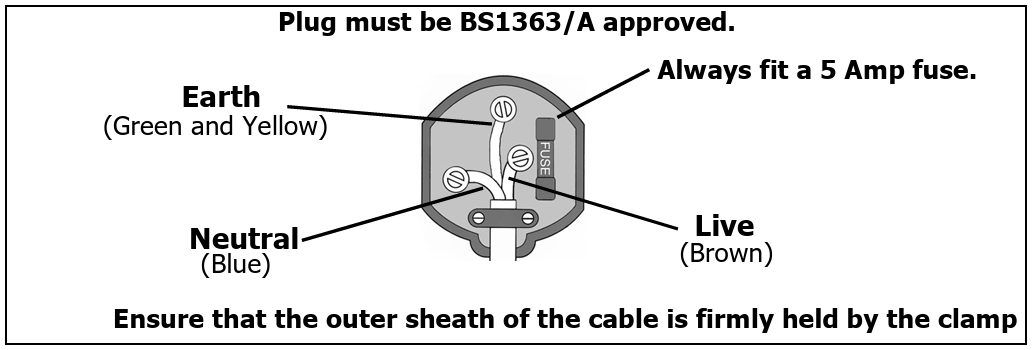

Before switching the product on, make sure that the voltage of your electricity supply is the same as that indicated on the rating plate. This product is designed to operate on 230VAC 50Hz. Connecting it to any other power source may cause damage. This product may be fitted with a non-rewireable plug.

The old plug must be disposed of safely, as insertion into a mains socket could cause an electrical hazard. If the colours of the wires in the power cable of this product do not correspond with the markings on the terminals of your plug, proceed as follows.

- The Blue wire must be connected to the terminal marked N or coloured Black.

- The Brown wire must be connected to the terminal marked L or coloured Red.

- The Yellow and Green wires must be connected to the terminal marked E or coloured Green.

We strongly recommend that this machine be connected to the mains supply via a Residual Current Device (RCD). If in any doubt, consult a qualified electrician. DO NOT attempt any repairs yourself.

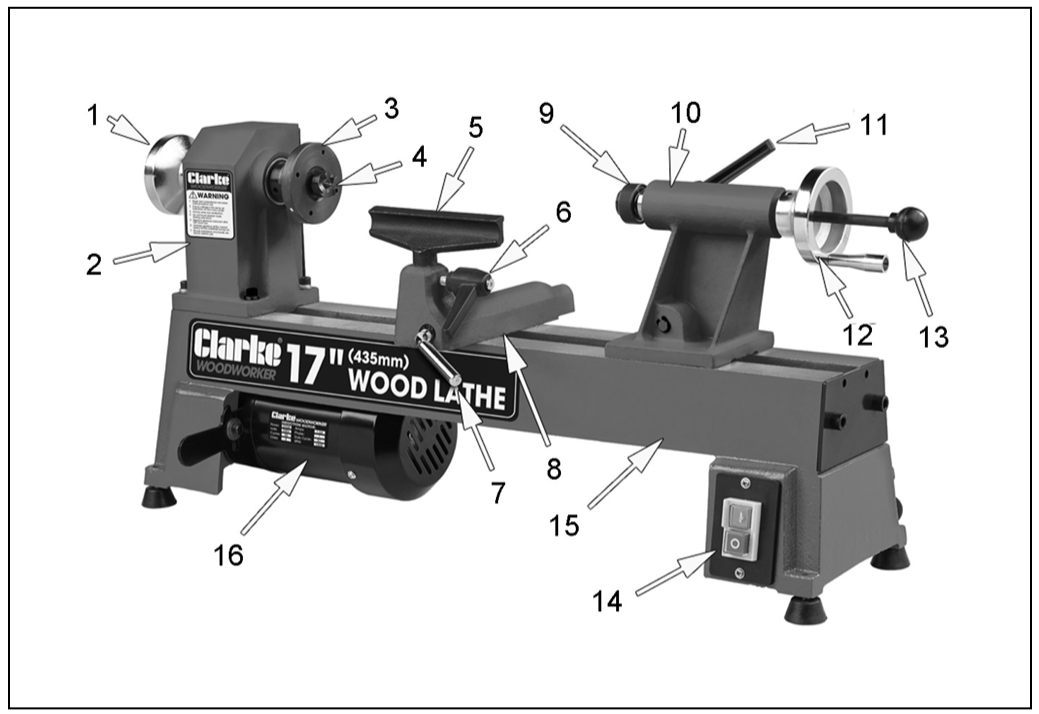

Overview

Ensure the wood lathe and its components suffered no damage during transit and that all components are present. Should any loss or damage be apparent, please contact your CLARKE dealer immediately.

The following components are supplied with the lathe assembly.

- Hand Wheel

- Headstock

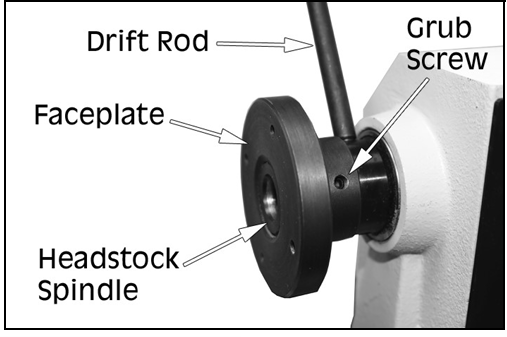

- Faceplate

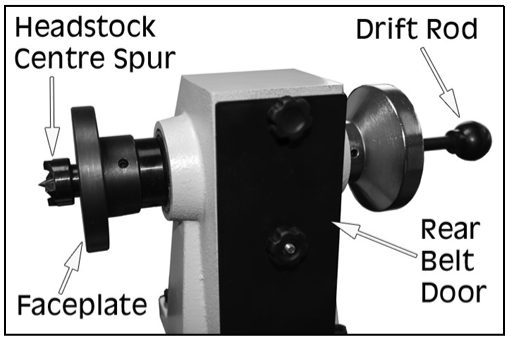

- Headstock Centre Spur

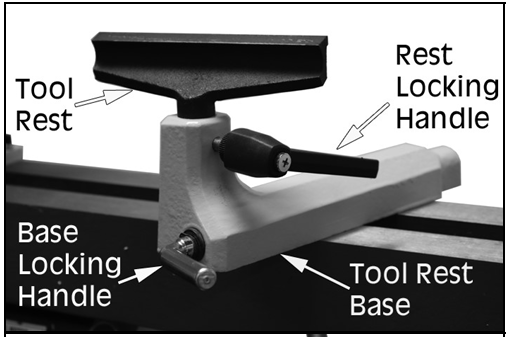

- 150mm Tool Rest

- Tool Rest Locking Handle

- Tool Rest Base Locking Handle

- Tool Rest Base

- Tailstock Centre Cup

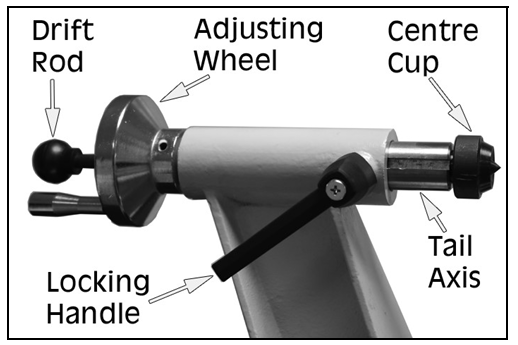

- Tailstock

- Tail Axis Locking Handle

- Tail Axis Adjusting Wheel

- Drift Rod

- Stop/Start Switch

- Bed

- Motor

- 3 x Hex Keys (3mm,6mm,8mm) (Not shown)

Assembly

- Fit the tailstock centre cup into the tail axis.

- Fit the tool rest into the tool rest base. Adjust to the required height and position using the rest locking handle and base locking handle.

- Install the headstock faceplate by screwing it onto the headstock spindle, using the drift rod as a counter lever. Lock the faceplate into place using the 2 x 3mm hex grub screws.

- Install the headstock centre spur by sliding it into the headstock spindle as shown.

Operation

- Always rotate the workpiece by hand before switching on the motor, and check that it does not strike the tool rest or bed.

- Always position the tool rest just above the centre line of the lathe.

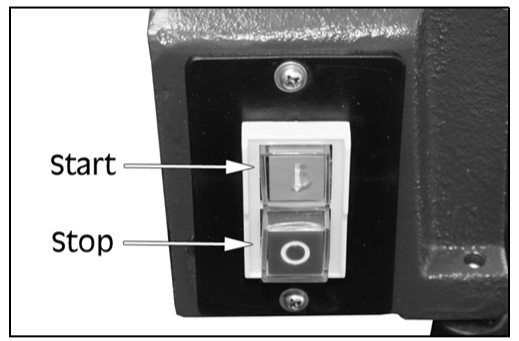

- Press the green push-button (I) to start the lathe. NOTE: Always use the lowest speed when starting a new workpiece, see Adjusting The Belt Position on page 11.

- When turning, always roughly turn the work to a round form at a slow speed.

- Take care that the turning tools do not suddenly bite into the workpiece.

Positioning

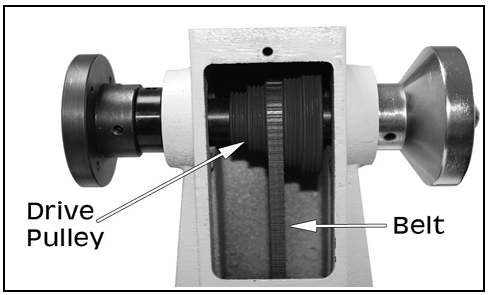

The lathe is fitted with a 5-step pulley setup, which allows for a range of speeds, as shown. Change the pulley range as follows.

- Unscrew the retaining plate on the headstock end of the bed for access to the motor pulley.

- Unscrew the rear belt door on the rear of the headstock for access to the drive pulley.

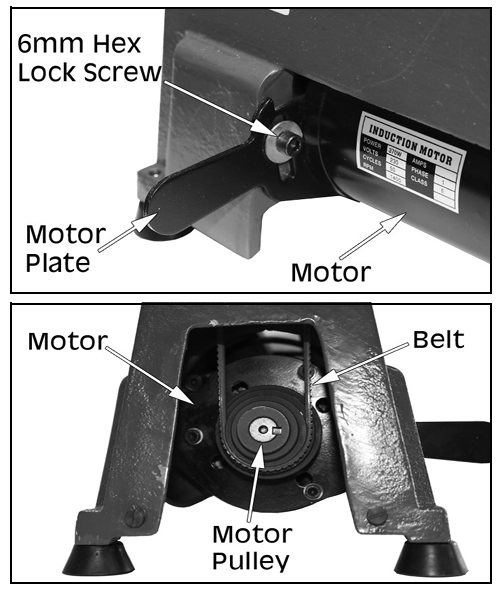

- Loosen the lock screw that is holding the motor plate using the 6mm hex key, allowing the motor plate to swivel upwards.

- Move the belt to the required pulleys as shown in the diagram above.

- After moving the belt, tighten the motor pulley by swivelling the motor plate downwards and tightening the locking screw.

- Turn on the lathe to make sure the belt is running consistently in its parallel grooves on the pulleys. If the belt is running smoothly, turn the power off and reattach the retaining plate and rear belt door.

Maintainance

- Vacuum clean any dust or shavings that Clarke CWL435 17-Inch Wood Lathe accumulate in or on the motor.

- Check all cables periodically and ensure that they are in good condition and not cracked.

- Check the tightness of the headstock mounting bolts.

- Check the drive belt for wear and replace it if it is frayed or otherwise damaged.

- Periodically lubricate the tail-stock, screw threads with engine oil such as SAE20 or SAE30 grade if they become stiff to use.

- Lightly lubricate the tail-stock and tool-post locking handles with oil if they become difficult to use.

- The ball bearings in the headstock and tailstock spindles are greased and permanently sealed at the factory and require no further lubrication.

Replacement

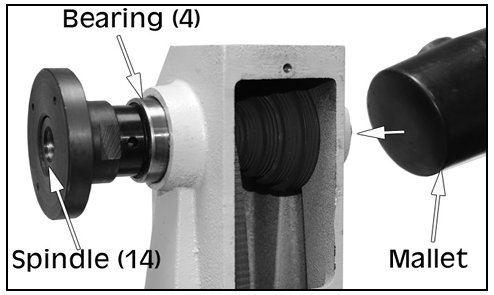

- To change the Drive Belt (53), Headstock Spindle (14) or Bearings (4), you must first loosen the Motor Plate and Belt, as mentioned in section Adjusting Belt Position on page 11.

- Remove the rear belt door (7) and knob (8).

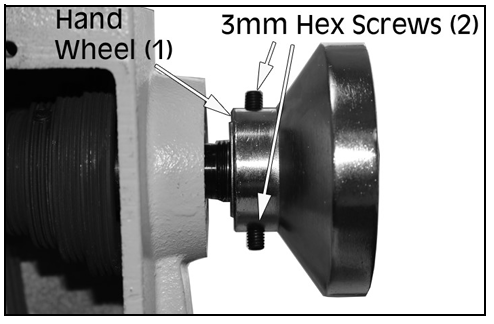

- Loosen the two 3mm hex screws (2) and unscrew the hand wheel (1).

- Loosen the 3mm hex screw (54) on the drive pulley (52).

- Tap out the spindle (14) using a mallet.

- To get the spindle completely out, use a flat-head screwdriver to tap it the rest of the way if needed.

- Replace the bearings, spindle or belt as required.

- BELT: You need only to move the spindle enough to Clarke CWL435 17-Inch Wood Lathe slide a new belt on.

- SPINDLE: You must knock the spindle completely out through both bearings.

- BEARINGS: After removal of the spindle, completely knock out the bearings from the inside of the headstock. This is best accomplished by inserting a long rod or screwdriver through one bearing inside the headstock toward the opposite bearing.

- Reinstall the hand wheel (1) and set screws (2).

- Tighten the pulley taper screw (69) and close the rear belt door (7)

Component Part Diagram

Part List

- Bed

- Hex Socket Screw M10 x 12 33 Lock Lever

- Retaining Plate

- Quill Adjusting Wheel

- Tailstock

- Lock Lever Assembly

- Eccentric Axis

- Tail Axis

- Taper Rod

- Ball Bearing 80102

- Cup Centre

- Headstock Spur Centre

- Faceplate

- Headstock Spindle

- Ball Bearing 80102

- Retaining Ring

- Retaining Ring

- Ball Bearing 80102

- Headstock

- Rear Belt Door

- Screw

- Hand Wheel

- Side Plate

- Hex Screw

- Drive Pulley

- Drive Belt

- Hex Screw

- Hex Screw M6 x10

- Motor Pulley

- Hex Screw

- Motor Plate

- Motor

- Lock Lever

- Retaining Ring

- Tool Rest

- Tool Rest Base

- Bolt

- Lock Plate

- Hex Nut

- Lock Handle for Tool Rest

- Lock Lever Assembly

- Bolt

- Lock Plate

- Hex Nut

- Power Cable

- Switch Faceplate

- Washer

- Screw

- On/Off Switch

- Washer

- Spring Washer

- Rubber Foot Washer

- Switch Box

- Washer

- Retaining Ring

- Tailstock Quill

- Bolt

- Quill Crank Handle

- Moving Knob

- Stationary Knob

- Sleeve

Associated Products

Wood Turning Chisel Set – CHT874

- 8-piece wood turning chisel set

- Part No. 1801874

4 Sided Diamond Sharpener – CHT593

- Multi-purpose sharpener with four different grits

- Part No. 1801593

SAE30 Motor Oil – 1 litre

- For lubricating the tailstock & screw threads

- Part No. 3050852

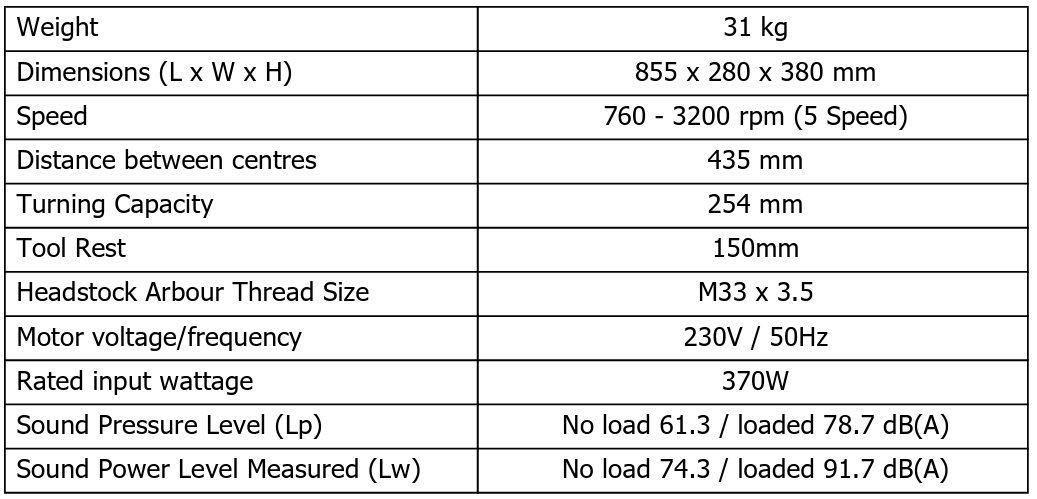

Specifications

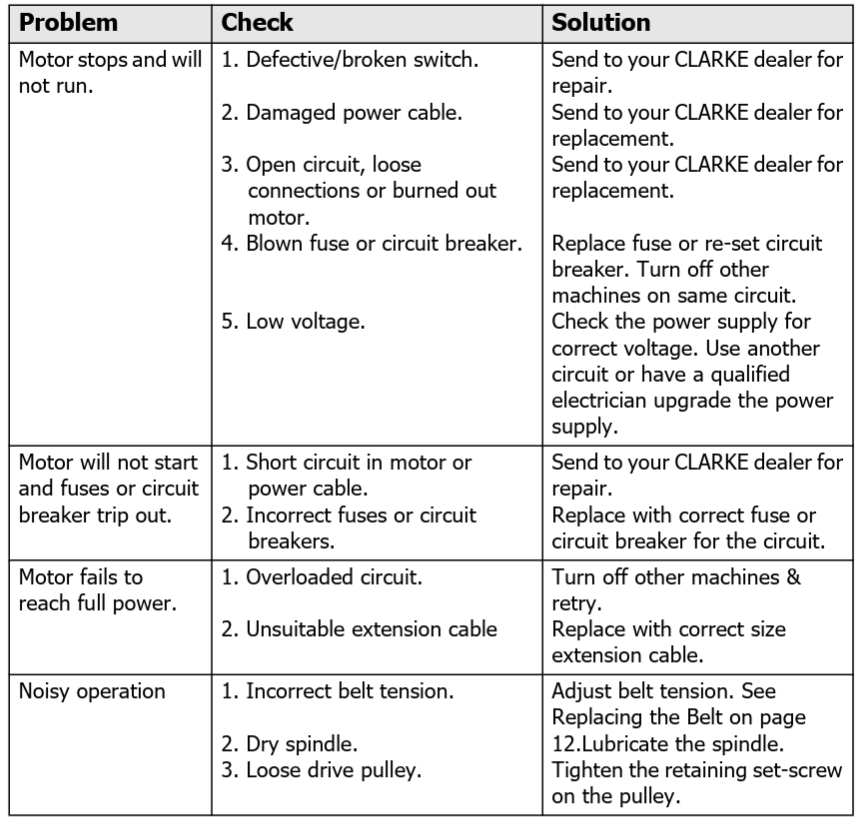

Troubleshooting

Environmental Protection

Recycle unwanted materials instead of disposing of them as waste. Through the purchase of this product, the customer is taking on the obligation to deal Clarke CWL435 17-Inch Wood Lathe with the WEEE in accordance with the WEEE regulations in relation to the treatment, recycling & recovery and environmentally sound disposal of the WEEE.

Guarantee

This CLARKE product is guaranteed against faulty manufacture for 12 months from the date of purchase. Please keep your receipt as proof of purchase. This guarantee does not affect your statutory rights.

Customer Service

- Tel: 0208 988 7400

- Website: parts@clarkeinternational.com

- Visit: service@clarkeinternational.com

FAQs

What size and type of wood can the Clarke CWL435 lathe handle?

The CWL435 is perfect for bowls, spindles, and other woodturning tasks because it can turn wood up to 17 inches in diameter and roughly 40 inches in length.

How do I safely mount wood on the lathe?

Before operating, always make sure the tool rest and tailstock are securely tight.

What safety gear should I use when operating the wood lathe?

Avoid wearing loose clothing or jewellery, put on a respirator or dust mask, and use safety glasses or a face shield. Keep your workspace tidy and always use sharp instruments.

How do I adjust the speed on the CWL435 lathe?

With the lathe’s variable speed control dial, you may change the speed based on the diameter and kind of wood. Higher speeds for smaller components and lower speeds for greater diameters.

What maintenance does the Clarke CWL435 require?

To guarantee safe operation, routinely clear away dust and debris, lubricate moving parts as directed, check belts for wear, and examine electrical components.

What tools are compatible with the lathe?

Make use of lathe-specific scrapers, gouges, parting tools, and woodturning chisels. To get the greatest results, make sure your tools are appropriate for your project and sharp.

How do I know when to replace the drive belt?

If you observe cracks, fraying, slippage, or strange noises while the belt is in use, replace it. For replacement instructions, consult the handbook.