Clarke TIGER 1800B Petrol Driven Power Washer

Safety Instructions

- DO NOT point the spray at other people, animals, electrical equipment, or the machine itself.

- DO NOT hold your finger over the high-pressure nozzle.

- DO NOT let children or untrained personnel use this machine.

- DO NOT operate the machine with any of the covers removed.

- DO NOT try to repair this machine. Always refer to your CLARKE service department for all repairs.

- DO NOT supply any liquid other than water to the water inlet.

- DO NOT use the detergent pickup facility to introduce flammable liquids/solvents, e.g., paint thinners, petrol, oil, as there is a risk of explosion.

- ALWAYS release the remaining pressure in the system; turn off the water supply and operate the trigger before you remove hoses or accessories.

- ALWAYS keep the machine dry and away from the water spray.

- ALWAYS use protective clothing and safety glasses. Loose particles and other items can be propelled at high speed by the water spray.

- ONLY use detergents that are suitable for pressure washers. We recommend that you use CLARKE Traffic Film Remover or CLARKE Wash and Wax (available from your dealer).

- High-pressure water jets can be dangerous; the jet must not be directed at a person or anything that they are wearing.

- High-pressure hoses, fittings, and couplings are important for the safety of the machine. Use only hoses, fittings, a nd couplings recommended by the manufacturer.

Symbols

- DO NOT direct the discharge

stream at persons or animals. Keep clear

of the nozzle. - NEVER direct spray toward

any electrical device or electrical outlet. - General Warning indicates that failing to follow these instructions could result in injury or damage to the machine.

- To reduce the risk of injury, read the manual before use.

- ALWAYS wear safety glasses when using this machine.

- No open flame, open ignition source, or smoking is prohibited

- No smoking

- Risk to breathing. Engine exhaust fumes can kill.

- For outdoor use only. Work in a well-ventilated area.

- Risk of injection or severe injury. Do not direct the discharge stream at persons or animals. Keep clear of the nozzle. This machine is to be used only by qualified operators.

- Risk of spray injury. Spray can propel objects. Always wear ANSI-approved Z87.1 Safety Glasses.

- Risk of chemical burn. Never spray acids, corrosive, or toxic chemicals. Use only cleaners formulated for pressure washers.

- Risk of electrocution. Never direct spray toward any electrical device or electrical outlet.

- Risk of unsafe operation. Keep children away from this equipment. Gun kicks back. Hold with both hands.

- Risk of hot surfaces. Recycle unwanted materials instead of disposing of them as waste. All tools, accessories, and packaging should be sorted, taken to a recycling centre, and disposed of in a manner that is compatible with the environment.

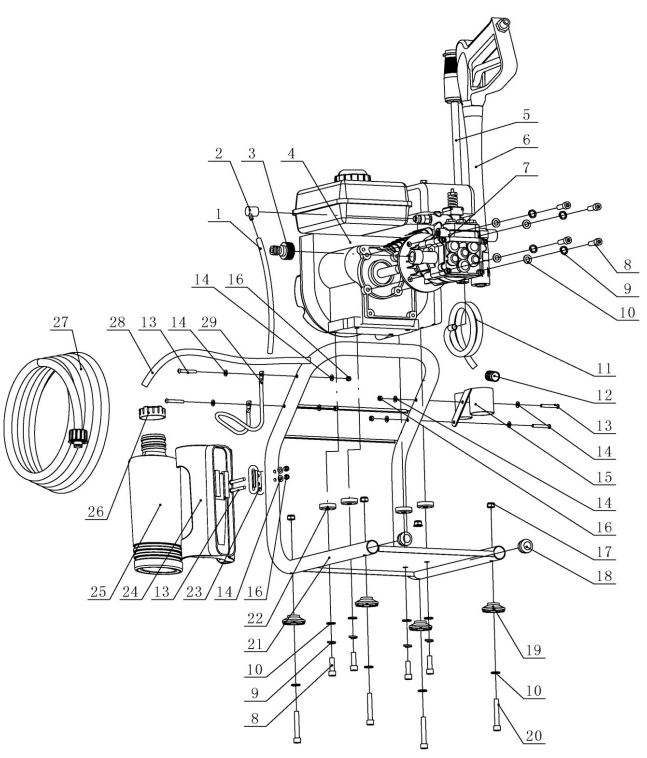

Part List

Description

- Drain Hose

- Thermal Relief Cap

- Inlet Connector

- Petrol Engine

- Lance

- Gun

- High-Pressure Pump

- Inner hex Bolt M8x25

- Spring Washer

- Washer

- Injection Hose

- Injection Filter

- Cross Bolt M5x35

- Washer

- Gun Holder

- Locknut M5

- Locknut M8

- Rubber Plug

- Rubber Foot

- Inner hex Bolt M8x40

- Frame

- Engine Isolator

- Water Bottle Hook

- Water Bottle Frame

- Water Bottle

- Water Bottle Cap

- High-Pressure Hose

- Water Pipe

- Hose Hook

Accessories

The range of accessories listed below may be purchased from your CLARKE dealer.

Item & Part Number

- 5 Litres Detergent (Traffic Film Remover): 3050821

- 25 Litres Detergent (Traffic Film Remover): 3050820

- 5 Litres Wash’n’ Wax: 3050815

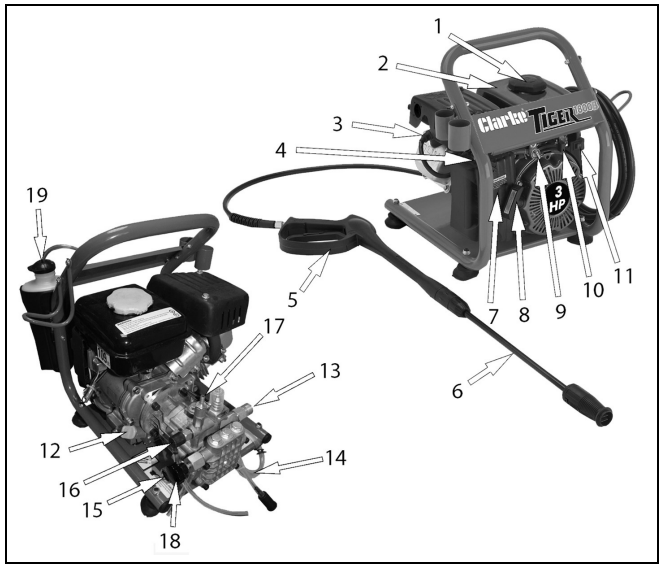

Overview

Description

- Fuel Tank Cap

- Fuel Tank

- Spark Plug

- Choke

- Gun Assembly

- Lance Assembly

- Air Filter Cover

- Recoil Starting Handle

- Fuel Valve

- Throttle

- Engine On/Off Switch

- Oil Filler Cap

- Water Outlet

- Detergent Hose

- Water Inlet

- Bypass Drain Hose

- Self-suction Valve

- Exhaust Valve

- Water Bottle

Unpacking & Assembly

Unpack your pressure washer and make sure that the following items are present. Contact your CLARKE dealer immediately if any parts are missing or damaged.

- 1 x Petrol Power Washer

- 1 X Hose Bracket

- 1 X Gun / Lance Bracket

- 1 X Tap Adaptor (Fitted To Unit)

- 1 X Output Hose For Gun

- 1 x Gun Assembly

- 1 x Lance Assembly

- 1 X Suction Hose

- 1 X Filter For Suction Hose

- 1 X Water Bottle

- 1 X Bottle Bracket

Assembly

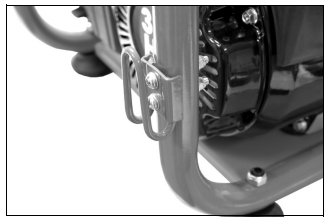

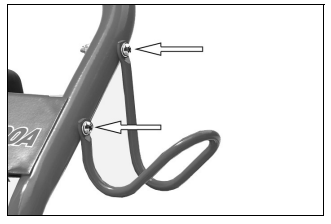

Fitting the Hose

Fit the hose storage bracket into the position shown and secure using the bolts, washers, and nuts supplied.

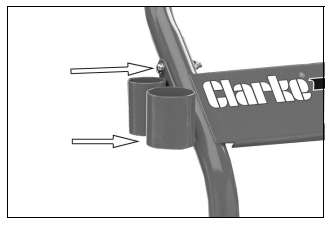

Fitting the Lance

Fit the lance storage bracket into the position shown and secure using the bolts, washers, and nuts supplied.

Fitting the Water

- Fit the bracket to the frame as shown using the bolts, nuts, and washers supplied.

- Slide the bottle holder over the bracket.

- Place the bottle in the holder.

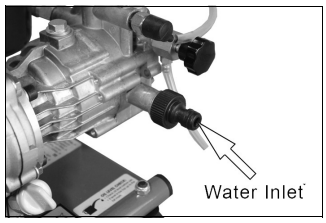

Connect the Water Supply

Always follow the regulations of your local water supplier. The pressure washer must never be connected to the drinking water supply without using a system separator (also known as a backflow preventer) available from most hardware stores.

- Connect a water supply hose (not supplied) to the water inlet.

- Use a good-quality water hose with a standard quick-fit coupling.

- This machine can draw its water, meaning you can use water not under pressure, such as rainwater collected in a water butt. See page 16.

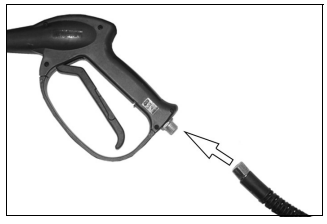

High-Pressure Hose

- Screw the high-pressure hose onto the gun assembly.

- Use a spanner to tighten the connector.

Connect the Hose

- Screw the hose to the pressure washer.

- Tighten the connector, hand-tight only. Do not use a spanner.

- Tighten the connector, hand-tight only. Do not use a spanner.

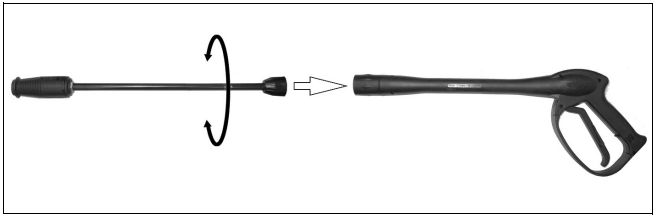

Attach the Lance

- Screw the lance onto the end of the gun assembly.

Before Use

The engine is supplied without any oil in it and must be filled to the correct level before use, see below.

Adding Engine Oil

- Turn the oil filler cap anticlockwise and remove it from the engine. Wipe the integral dipstick with a clean cloth.

- Insert the oil filler cap back into place and then remove it again.

- Do not screw it in when doing this.

- If the oil reads low on the dipstick, add oil to the oil reservoir (Max 0.6L).

- We recommend the use of SAE10W-30 oil.

- Do not overfill the oil reservoir.

- Replace the oil filler cap.

Adding Fuel

- Remove the fuel tank cap.

- Just inside the fuel tank is a fuel strainer, which should be checked periodically, and any contaminants that have accumulated must be removed.

- Just inside the fuel tank is a fuel strainer, which should be checked periodically, and any contaminants that have accumulated must be removed.

- Pour unleaded petrol through the fuel strainer and into the fuel tank.

- Do not fill above the fuel strainer shoulder.

- Use unleaded petrol with a pump octane rating of 86 or higher.

- After refuelling, tighten the fuel tank cap securely.

Starting Your Pressure

- Turn the water supply on, and make sure that the tap is fully open.

- Set the choke lever to the START position.

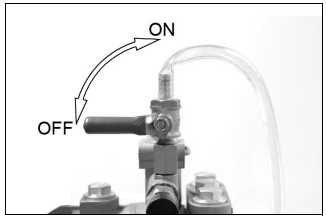

- Set the fuel supply valve to the ON position.

- Slide the throttle 3/4 of the way to the left.

- Set the engine switch to the on (I) position.

- Pull the recoil starting handle lightly until you start to feel resistance, and then pull up sharply to start the engine.

- You may have to do this more than once.

- You may have to do this more than once.

- Slide the choke lever to the RUN position.

- The pressure washer is now ready for use.

- The pressure washer is now ready for use.

- Release the trigger lock.

- Ensuring that you have a firm footing and that you are also holding the gun assembly and spray lance firmly, pull the trigger on the gun to start water flow.

- The lance and gun will kick back when the trigger is first pulled.

- The lance and gun will kick back when the trigger is first pulled.

Operation

- Release the trigger.

- The pressure washer will automatically go into bypass mode.

- If you notice water coming from the drain tube attached to the pump, please note that this is a safety feature and should be expected.

- It cools the pump by releasing some of the hot water within the pump and replacing it with fresh ‘cool’ water.

- Rotate the trigger lock to the locked position.

Adjust the Nozzle

The nozzle is adjustable to allow you to adjust the water delivery from a narrow jet of water to a wide spray. To adjust the nozzle, proceed as follows:

- Hold the shaft of the lance in one hand.

- Twist the nozzle with the other hand.

- The spray varies between narrow and wide as you turn the nozzle.

- The narrow jet should be used to clean small areas where a small spray is required.

- The wide spray should be used for cleaning large areas.

Adjust the Pressure

Hold the rear of the nozzle and slide the front of the nozzle forward to low pressure and backwards for high pressure. Other ways to adjust the pressure include. Changing the distance you are from the surface being cleaned and adjusting the spray to a wider angle (lowers the pressure).

Applying Chemicals

To improve the cleaning performance, you can introduce chemical cleaning agents (detergents) to the water jet using the detergent pickup hose.

- Place the detergent pickup hose into a container holding the chemical/cleaning

solution.- Only use detergents recommended for use with pressure washers, such as CLARKE Traffic Film Remover, which is a powerful, low-foaming agent for car cleaning, patio cleaning, etc., or CLARKE Wash & Wax, both available from your CLARKE dealer.

- Hold the rear of the nozzle and slide the front of the nozzle forward to low pressure.

- Spray the detergent onto the vehicle, patio, etc.

- Allow the detergent a little time to work itself into the grime.

- To rinse, remove the detergent pickup hose from the container holding the chemical/ cleaning solution and use the pressure washer as normal.

SHUTTING DOWN

- After each use, if you have applied chemicals, place the detergent pickup hose into a container of clean water and run clean water through the detergent pickup hose to flush the system thoroughly.

- Failure to do so could cause damage to the pump.

- Move the throttle control lever to the right.

- Turn off the engine switch.

- NEVER turn the water off with the engine running.

- NEVER turn the water off with the engine running.

- Turn the water supply off at the tap.

- Release the pressure in the pump and hose by squeezing the trigger for a few seconds until no more water comes out of the nozzle.

- Turn off the fuel supply valve.

- Rotate the trigger lock to the locked position.

Water Connection

This machine can draw its water, meaning you can use water not under pressure, such as rainwater collected in a water butt. To do this, you must carry out the following procedure.

- Remove the quick connector from the water inlet.

- Attach the filter to the end of the suction pipe supplied.

- Remove the water inlet filter.

- Connect the other end of the suction pipe to the pressure washer.

- Fill the supplied bottle with water.

- Connect the hose from the bottle to the self-suction valve shown.

- Start the pressure washer. See “Starting your Pressure Washer” on page 11.

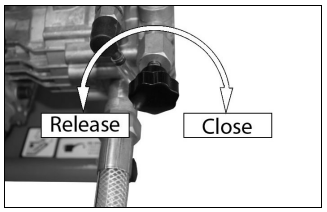

- Release the exhaust valve.

- Turn the self-suction valve to the on position.

- Release the trigger lock and pull the trigger.

- When the water spray is at high pressure, close the exhaust valve and set the suction valve to the OFF position.

Maintainance

- Switch off the pressure washer and the water supply.

- Pull the trigger to release any water pressure.

- Disconnect the lance from the gun assembly.

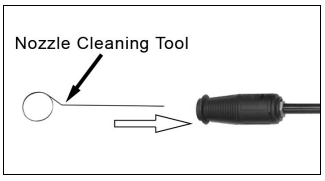

- Remove all blockages with the nozzle cleaning tool provided and back flush with clean water.

- Run water into the end of the lance for 30 seconds to back flush loose particles.

- Reconnect the lance to the gun assembly and turn on the water supply.

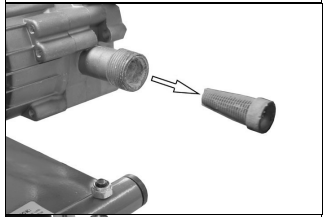

Inter Filter

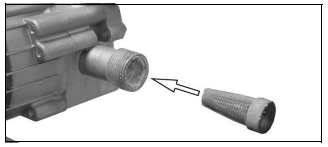

- Remove the filter from the water inlet of the pump as shown.

- Clean the filter by flushing both sides with water.

- Replace the filter in the water inlet.

- Do not operate without the filter properly installed.

- Do not operate without the filter properly installed.

Fuel Strainer

Just inside the fuel tank is a fuel strainer; check this periodically and remove any contaminants that may have accumulated.

- Open the fuel tank cap.

- Remove the fuel strainer.

- Flush away any contaminants.

- Replace the fuel strainer.

- Do not operate the pressure washer without Clarke TIGER 1800B Petrol Driven Power Washer the fuel strainer properly installed.

- Do not operate the pressure washer without Clarke TIGER 1800B Petrol Driven Power Washer the fuel strainer properly installed.

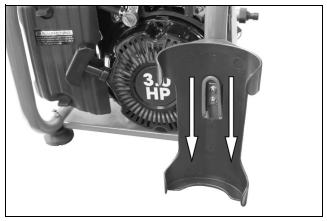

Air Filter

- Remove the two screws on the air filter cover.

- Remove the air filter cover.

- Remove the air filter element.

- Wash it in a solution of warm water and mild detergent.

- Rinse thoroughly and leave it to dry. Once it is completely dry, immerse the filter in clean engine oil and squeeze the filter to remove excess oil.

- If the air filter is damaged, contact the CLARKE spare parts department for a replacement.

- Replace the filter in its original position and refix the air filter cover.

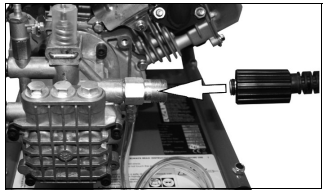

Spark Plug

- Remove the spark plug cap from the spark plug.

- Use the supplied spark plug spanner to remove the spark plug.

- Remove any carbon that has accumulated around the sparkplug.

- Check the overall condition of the spark plug and replace it if necessary.

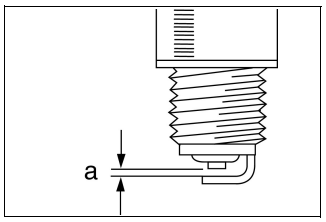

- Check the spark plug gap (a), it should be between 0.7 and 0.8 mm. Adjust if necessary.

- Reinstall the spark plug and refit the spark plug cap.

Storage

- Follow the shutdown procedure on page 14.

- Disconnect the high-pressure hose and drain all water from the hose.

- Coil the hose and store the gun/lance in the holders located on the side frame of the pressure washer.

Procedure

Make sure that the pressure washer has been thoroughly cleaned before storing it in a clean, dry place. For long-term storage, see page 20.

Long Term Storage

For long-term storage

- The petrol tank should be drained.

- Ensure that the engine is cold before draining the tank.

- Remove the fuel tank cap and use a pump-type siphon to drain the petrol into an appropriate, clean container.

- Do not store petrol for long periods.

- Dispose of excess petrol in an environmentally Clarke TIGER 1800B Petrol Driven Power Washer safe way. Your local recycling centre can advise you on the best method of disposal.

- After the petrol tank has been drained, start the engine and allow it to use any petrol that may remain in the engine or fuel pipe.

- Make sure that the power washer has been thoroughly Clarke TIGER 1800B Petrol Driven Power Washer cleaned before storing it in a clean, dry place.

Specifications

Engine

- Engine type: Petrol (unleaded). OHV Single Cylinder 4-stroke forced air cooling

- Capacity/displacement: 98 cc

- Oil Capacity: 0.6 L

- Lubrication Grade: SAE10W-30

- Fuel Tank Capacity: (Litres) 1.6L

Water Connection

- Max. Feed Temperature: 60 °C

- Max. Feed Pressure: 3-6 Bar

Performance Data

- Maximum Pump Pressure: 110 Bar

- Maximum Suction Height: 1.5 m

- Working Pressure: 70 Bar

- Maximum Water Flow: 6 I/min

Noise & Vibration

- Sound Pressure Level LpA: 86.7 dB(A)

- Sound Power Level LWA: 100 dB(A)

- Guaranteed Sound Power Level LWA: 102 dB(A)

- Uncertainty Factor: K 2.28

- Vibration: 4.494 m/s

- Uncertainty Factor: K 1.5

Dimensions

- Length: 425 mm

- Width: 315 mm

- Height: 430 mm

- Weight: 19 kg

Exploded Diagram

Troubleshooting

| PROBLEM | CAUSE | SOLUTION |

| The engine will not start (see engine manual for further engine troubleshooting. | No fuel. | Add fuel. |

| Low oil. | Add oil. | |

| Pressure builds up after two pulls on the recoil starter or after initial use. | Squeeze the gun trigger to relieve the pressure. | |

| Spark plug lead not attached. | Attach the spark plug lead. | |

| The engine switch is in the OFF position. | Set the engine switch to the ON position. | |

| The choke lever is set to the on position when the engine is already warm. | Set the choke lever to the OFF (right) position. | |

| Fuel valve closed. | Open the fuel valve. | |

| Oil is leaking at the pump | Oil seals are worn. | Have them replaced by your dealer. |

| Worn O-rings. | Have them replaced by your dealer. | |

| Lack of pressure (initial use) | Leak in the high-pressure hose fitting. | Tighten the fitting, use sealant tape if required. |

| The nozzle is obstructed. | Clear the nozzle. | |

| The water filter screen is clogged. | Remove and clean the filter. | |

| Air in the hose. | Turn off the engine. Turn off the water supply. Disconnect the water source from the pump inlet and turn on the water source to expel the air from the hose. When all the air has been removed, turn off the water supply and reconnect the hose. Turn on the water supply and pull the trigger to expel any air in the gun/lance. |

Guarantee

This product is guaranteed against faulty manufacture for 12 months Clarke TIGER 1800B Petrol Driven Power Washer from the date of purchase. Please keep your receipt, which will be required as proof of purchase. This guarantee is invalid if the product is tampered with in any way or not used for the purpose for which it was intended. Faulty goods should be returned to their place of purchase; no product can be returned to us without prior permission. This guarantee does not affect your statutory rights.

Environmental Recycling

One of the most damaging sources of environmental pollution is oil products. Never throw away used oil with domestic refuse or flush it down a sink or drain. Collect any Clarke TIGER 1800B Petrol Driven Power Washer oil in a leak-proof container and take it to your local waste disposal site. Should any components become completely unserviceable and require disposal, plastic and metal should be disposed of according to local regulations.

Customer Service

- Tel: 0208 988 7400

- Website: parts@clarkeinternational.com

- Visit: service@clarkeinternational.com

FAQs

What type of engine powers the Clarke TIGER 1800B?

With its dependable petrol engine, the TIGER 1800B offers portable high-pressure water cleaning without requiring electricity.

What is the maximum pressure output of the power washer?

With a maximum pressure of about 1800 PSI (pounds per square inch), the power washer is appropriate for demanding cleaning jobs.

Can the TIGER 1800B be used with hot water?

No, this model is only meant to be used with cold water. Using hot water might shorten the washer’s lifespan and harm the pump.

What type of fuel should I use for the engine?

Make use of petrol (unleaded) with the recommended octane rating. For the best engine performance, always use fresh fuel.

How do I start the power washer?

Pull the recoil starting cord hard until the engine starts after turning on the fuel valve, adjusting the choke as necessary, and turning the ignition to “on.”

What maintenance is required to keep the TIGER 1800B in good condition?

To avoid accumulation, regularly check and replace the engine oil, clean the air filter, examine the spark plug and flush the pump system after each usage.

How often should I change the engine oil?

After five hours of usage, then every fifty hours, or as advised by the handbook, change the oil.

Can I use detergents with this power washer?

Indeed, a detergent injection mechanism is a feature of the TIGER 1800B. Use only the detergents that are suggested for pressure washers, and pay close attention to the dilution recommendations.