Labnet S2020-P4-B Orbit Digital Shaker

Introduction

The Labnet Orbit™ Digital Shakers are intended for shaking microliter plates, tubes, bottles, flasks, dishes, and other laboratory vessels. The shakers are driven by asynchronous motors, which enable silent operation and constant shaking speed independent of the load or power supply fluctuations.

Each shaker device consists of two main components:

Safety Information

- Always plug the unit into a properly grounded and fused outlet.

- Do not use the device near water sources. Take care so that water does not fall on the device, especially during cleaning procedures.

- Do not use the device in a caustic or explosive atmosphere.

- There are no user-serviceable parts in the unit. Opening the unit may void the warranty. In case of a malfunction or liquid being spilled into the unit, unplug the device from its power outlet and contact Corning Customer Service.

Installation

Unpacking

Before starting installation, carefully examine the shaker for damage or missing parts.

- Open the box, and lift the device together with the inner packing out of the box.

- Remove the inner packing and check that the shaker has not been visibly damaged during transportation. Keep the packing material until you are sure that the shaker works properly.

- Check information on the rear data label and verify the following are correct:

- Model

- Serial number

- Electrical rating

- Should any kind of damage have occurred during transportation, contact the carrier immediately. The carrier is responsible for shipping damage.

Selecting the Location

- Put the device on a horizontal, leveled, and stable surface.

- Leave enough space around the device for normal air circulation (4 in./10 cm minimum).

- Leave enough space around the device for easy access and maintenance.

- Do not use the device in surroundings where there are major temperature and humidity fluctuations. Also, avoid locations in direct sunlight or places near devices that produce heat.

- Avoid locations with excessive vibrations.

Attaching the Power Cord

Fit the main power cord, which is included in the package, into the power receptacle on the shaker. Connect the other end of the cord to a properly grounded wall outlet.

To avoid interference from noise, surges, and spikes, a dedicated line is preferred. If no such line is available, avoid lines to which powerful electric motors, refrigerators, and similar devices are connected.

Be careful when you plug the cord into a grounded wall socket. Do not touch the plug with wet hands. Do not pull the plug by the cord.

Installing Shaker Platforms

- Labnet Orbit P4

- The unit comes with the platform already installed.

Labnet Orbit™ 300

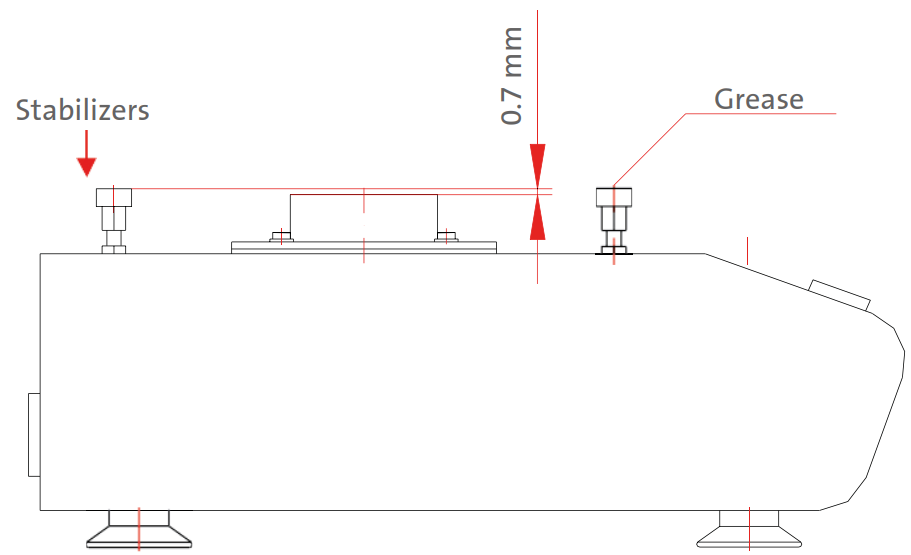

Before you attach the platform, make sure that the slide stabilizers are properly fastened, adjusted, and lubricated with the included grease. The flat mat platform has a circular cut-out in the rubber and screw holes in the center. Remove the cutout rubber circle and screw down the four screws onto the shaker.

After attaching the platform, remove the non-adhesive backing paper from the rubber circle and paste it back into place. The grease that you use to lubricate the slide stabilizers is sufficient for 1,000 working hours (1 year). After that time, you should remove the shaking platform and clean, adjust, and re-grease the slide stabilizers. If they are worn out, you should replace them with new stabilizers and set them to the appropriate height.

Labnet Orbit 1000 and Orbit 1900

The Orbit 1000 and Orbit 1900 shakers have a variety of platforms to meet most shaking needs. These platforms mount to the shakers via four mounting platforms, which easily plug into four rubber mount points on the top of the shaker.

Operating Instructions

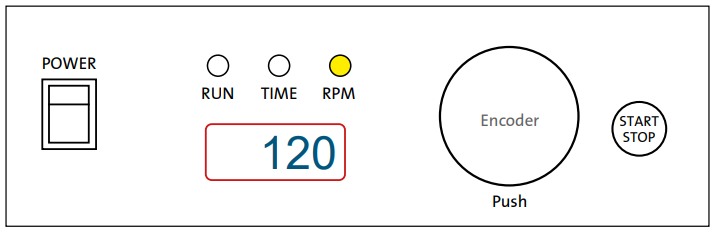

Control Panel

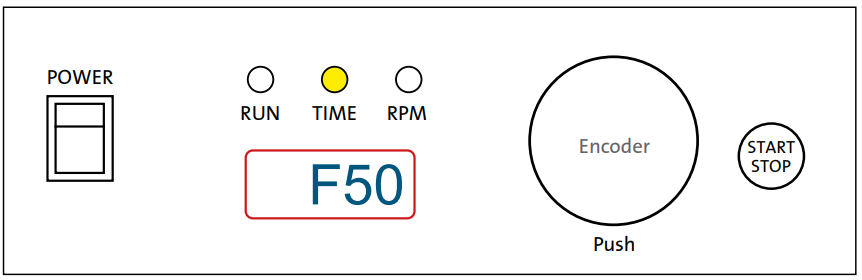

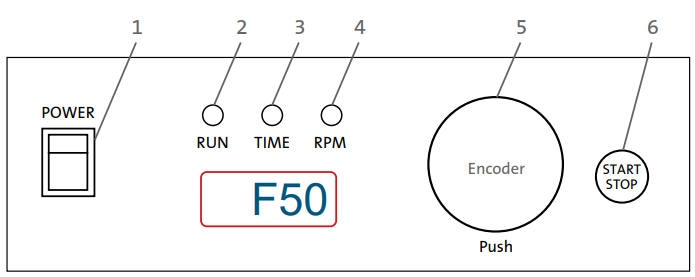

- POWER switch: Turns the shaker ON (power switch illuminates) or OFF

- RUN green light: Illuminates when the shaker is running

- TIME yellow light: Illuminates when the shaker is set on time

- RPM yellow light: Illuminates when the shaker is set on RPM

- ENCODER: By rotating the encoder knob right (+) or left (-), you can change the set TIME or RPM.

- START/STOP button: START or STOP operation

Basic Operation

- Press the POWER switch on the control panel. The Labnet Orbit™ Digital Shaker automatically detects the supply frequency of 50 or 60Hz, and displays F50 or F60.

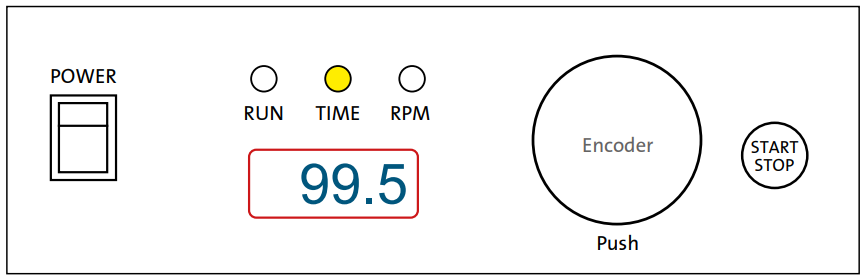

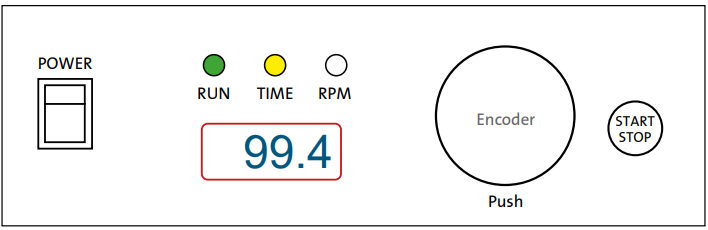

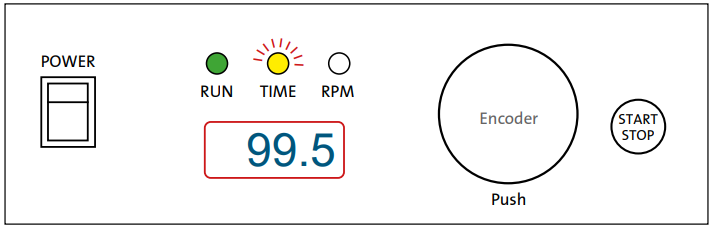

- Then the display switches to show the set time and illuminates the Time light.

- The time signal light is on. By rotating the encoder knob right (+) or left (-), the set time can be selected from 30 sec. to 99 min. 50 sec.:

- 99.5 = 99 min. 50 sec.

- 9.59 = 9 min. 59 sec.

- 0.30 = 30 sec

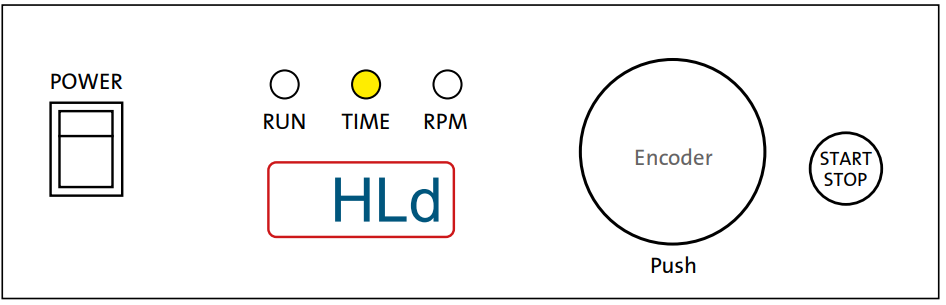

- If you want to set the timer to Hold, turn the knob left or right until “HLd” is displayed. You can reach the “HLd” function by setting it to under 0.30 or above 99.5.

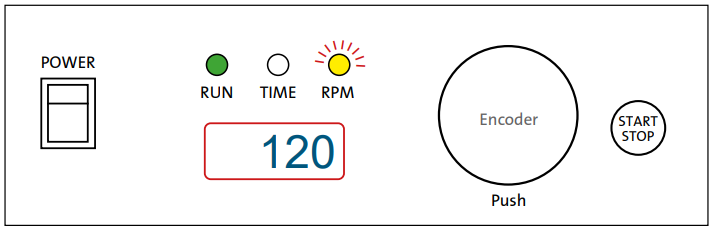

- Push the encoder knob to switch modes between time set mode and RPM set mode. The RPM signal light is on. By rotating the encoder knob right (+) or left (-), the desired RPM can be selected:

- 34 = 340 rpm

- 120 = 1,200 rpm

- Press the START/STOP button to start the operation. RUN and TIME signal lights. Shaker runs and counts down time from the set value.

- Push the encoder knob to switch modes between time set mode and RPM set mode. The RPM signal light is on. By rotating the encoder knob right (+) or left (-), the desired RPM can be selected:

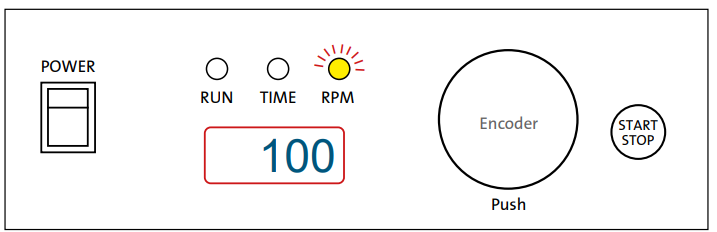

Changing the RPM during shaking

- Push the encoder knob to put the shaker into RPM set mode (RPM signal light will be on).

- Rotate the encoder knob right (+) or left (-) to set the desired value. In the meantime RPM signal light will flash.

- When you stop rotating the encoder knob, the signal light for RPM will stop flashing after 2 seconds.

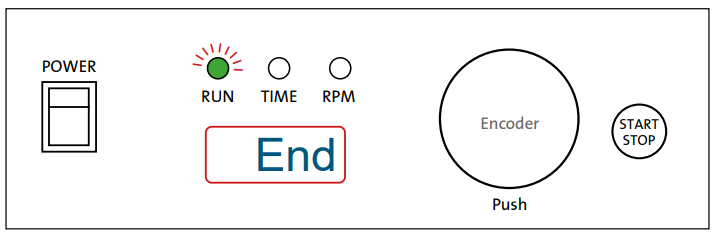

- When the run time has elapsed or when you press the START/STOP button, End will show on the display, and the Run light will flash.

- When the shaker completely stops, the set speed and time will return to the last programmed values.

Additional Operations

- If you want to view the set value for RPM during shaking, rotate the encoder knob for ONE CLICK right (+) or left (-). The RPM signal light will then flash for 2 sec., and the display will show the set RPM, and the light will stop flashing.

- If you want to view the set value for TIME during shaking, rotate the encoder knob for ONE CLICK right (+) or left (-). The time signal light will then flash for 2 sec., and the display will show the set TIME, and the light will stop flashing.g

Maintenance and Cleaning

Before cleaning the device, unplug the main cord from the wall socket. Except for the occasional maintenance described in Section 4.0 of this manual, no scheduled maintenance is normally required. However, an experienced technician should regularly check the device’s operation at least once a year to make sure it is operating correctly.

- Regular cleaning of the housing is recommended.

- The housing of the shaker can be cleaned with special cleaners for polyurethane (plastic) surfaces.

- A damp (not wet) cloth is recommended.

Specifications

Orbit P4

| Motor Power | 15W |

| Fuse 120V 230V | 2 x T 1A L 250V 2 x T 0.25A L 250V |

| RPM Regulation | Digital, load independent, from 100 to 1,200 rpm (1,400 rpm, 120V version) in 10 rpm steps |

| Shaker Orbit | 3 mm |

| Timer | 30 sec. to 99 min. 50 sec. in 10-second steps (under 10 min. in 1-second steps), timer HOLD function |

| Maximum Load | 0.66 lbs. (0.3 kg) |

| Dimensions (W x L x H) | 7.4 x 11.8 x 5.9 in. (18.8 x 30 x 15 cm) |

| Weight | 9.5 lbs. (4.3 kg) |

| Ambient Operation Range | 5°C to 40°C, up to 85% RH, non-condensing |

Orbit™ 300

| Motor Power | 15W |

| Fuse 120V 230V | 2 x T 1A L 250V 2 x T 0.25A L 250V |

| RPM Regulation | Digital, load independent, from 100 to 1,200 rpm in 10 rpm steps |

| Shaker Orbit | 3 mm |

| Timer | 30 sec. to 99 min. 50 sec. in 10-second steps (under 10 min. in -1-second steps), timer HOLD function |

| Maximum Load | 4.4 lbs. (2 kg) |

| Dimensions (W x L x H) | 10.3 x 13.3 x 5.1 in. (26.2 x 33.7 x 13 cm) |

| Weight | 12.35 lbs. (5.6 kg) |

| Ambient Operation Range | 5°C to 40°C, up to 85% RH, non-condensing |

Orbit 1000

| Labnet Orbit 1000 Electric Power Supply 120V 230V | 120V ± 10%, 50/60Hz 230V ± 10%, 50/60Hz |

| Motor Power | 15W |

| Fuse 120V 230V | 2 x T 1A L 250V 2 x T 0.25A L 250V |

| RPM Regulation | Digital, load independent, from 20 to 300 rpm in 1 rpm steps |

| Shaker Orbit | 19 mm |

| Timer | 30 sec. to 99 min. 50 sec. in 10-second steps (under 10 min. in 1-second steps), timer HOLD function |

| Maximum Load | 9 lbs. (4 kg) |

| Dimensions (W x L x H) | 10.3 x 13.3 x 5.1 in. (26.2 x 33.7 x 13 cm) |

| Weight | 16 lbs. (7.3 kg) |

| Ambient Operation Range | 5°C to 40°C, up to 85% RH, non-condensing |

Orbit 1900

| Electric Power Supply 120V 230V | 120V ± 10%, 50/60Hz 230V ± 10%, 50/60Hz |

| Motor Power | 50W |

| Fuse 120V 230V | 2 x T 2A L 250V 2 x T 1A L 250V |

| RPM Regulation | Digital, load independent, from 25 to 300 rpm in 1 rpm step |

| Shaker Orbit | 19 mm |

| Timer | 30 sec. to 99 min. 50 sec. in 10-second steps (under 10 min. in 1-second steps), timer HOLD function |

| Maximum Load | 22 lbs. (10 kg) |

| Dimensions (W x L x H) | 15.3 x 18.3 x 6.2 in. (39 x 46.5 x 16 cm) |

| Weight | 68.35 lbs. (31 kg) |

| Ambient Operation Range | 5°C to 40°C, up to 85% RH, non-condensing |

Accessories

Labnet Orbit™ 300

Cat. No. Description Qty/Pk

| S2030-10 | Platform for four microplates | 1 |

| S2030-12 | Platform with a non-slip rubber mat | 1 |

| S2030-13 | Spring-loaded platform for flasks, bottles, or tube racks | 1 |

Labnet Orbit 1000

| 1000 Cat. No. | Description | Qty/Pk |

| S2031-12 | Flat platform with non-slip rubber mat (30 x 30 cm) | 1 |

| S2032-12D | Two stacked platforms with a non-slip rubber mat (30 x 30 cm) | 1 |

| S2031-13 | Spring-loaded platform for flasks, bottles, or tube racks | 1 |

| S2031-18 | Flask clamp platform (clamps sold separately) | 1 |

Labnet Orbit 1900

| Cat. No. | Description | Qty/Pk |

| S2040-12 | Flat platform with non-slip mat (40 x 50 cm) | 1 |

| S2040-15 | Universal bar clamp platform for holding a variety of containers | 1 |

| S2040-18 | Flask clamp platform (clamps sold separately) | 1 |

Clamps for Erlenmeyer Flasks

| Cat. No. Description | Qty/Pk | |

| S2040-25 | Clamp for a 25 mL Erlenmeyer flask Orbit 1000 (max. 16) Orbit 1900 (max. 28) | 1 |

| S2040-50 | Clamp for a 50 mL Erlenmeyer flask Orbit 1000 (max. 16) Orbit 1900 (max. 28) | 1 |

| S2040-85 | Clamp for a 125 mL Erlenmeyer flask Orbit 1000 (max. 16) Orbit 1900 (max. 28) | 1 |

| S2040-99 | Clamp for a 250 mL Erlenmeyer flask Orbit 1000 (max. 9) Orbit 1900 (max. 20) | |

Troubleshooting

| The power switch does not light up | Check the power source. Check fuses. |

| Shaker stalls – Message Er1 | Power the unit down, then restart. |

| The display does not light up Message Er2, Er3, or Er4 on display | Contact Corning Customer Service. |

Should you have a question about the operation of the Labnet Orbit™ Digital Shakers or if service is required, contact your Corning representative. Do not send in a unit for service without first calling to obtain a repair authorization number. Should the unit require return to Corning for service, it should be properly packed to avoid damage. Any damage resulting from improper packaging shall be the responsibility of the user.

Maintenance and Cleaning

Before cleaning the device, unplug the main cord from the wall socket. Except for the occasional maintenance described in Section 4.0 of this manual, no scheduled maintenance is normally required. However, an experienced technician should regularly check the device’s operation at least once a year to make sure it is operating correctly.

- Regular cleaning of the housing is recommended.

- The housing of the shaker can be cleaned with Labnet S2020-P4-B Orbit Digital Shaker special cleaners for polyurethane (plastic) surfaces.

- A damp (not wet) cloth is recommended.

Limited Warranty

Corning Incorporated (Corning) warrants that this product will be free from defects in material and workmanship for a period of one (1) year from the date of purchase. Corning’s sole obligation shall be to repair or replace, at its option, any product or part thereof that proves defective in material or workmanship within the warranty period, provided the purchaser notifies Labnet S2020-P4-B Orbit Digital Shaker Corning of any such defect. Corning is not liable for any incidental or consequential damages, commercial loss, or any other damages from the use of this product.

Corning’s Customer Service team will help arrange local service where available or coordinate a return authorization number and shipping instructions. Corning may elect for on-site service for larger equipment. Some states do not alllimitationsion on the length of implied Labnet S2020-P4-B Orbit Digital Shaker warranties or the exclusion or limitation of incidental or consequential damages. This warranty gives you specific legal rights. You may have other rights that vary from state to state. No individual may accept for, or on behalf of Corning, any other obligation of liability, or extend the period of this warranty.

Warranty/Disclaimer

Unless otherwise specified, all products are for research use Labnet S2020-P4-B Orbit Digital Shaker or general laboratory use only.* Not intended for use in diagnostic or therapeutic procedures. Not for use in humans. Corning Life Sciences makes no claims regarding the performance of these products for clinical or diagnostic applications. *For a listing of US medical devices, regulatory classifications, or specific information on claims, visit www.corning.com/resources.

Equipment Disposal

According to Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on waste electrical and electronic equipment (WEEE), this product is marked with the crossed-out wheeled bin and must not be disposed of with domestic waste. Consequently, the buyer shall follow the instructions for reuse and recycling of waste electronic and electrical equipment (WEEE) provided with the products and available at www.corning.com/weee.

Customer Service

- Website: www.labnetlink.com.

- Visit: www.corning.com/lifesciencs

- Visit: www.corning.com/resources

- USA/Canada: 1.800.492.1110

- Others: +1.978.442.2200

- North America: 978.442.2200

- Australia/New Zealand: 61 427286832

FAQs

What is the shaking speed range of this model?

To meet different mixing needs, the shaker has a speed range of 30 to 300 RPM.

How do I set the shaking speed and timer?

The control panel’s excellent LCD makes it simple to program the speed and timing.

What is the maximum load capacity of the shaking platform?

For steady and effective shaking, the platform can sustain up to 10 kg of uniformly distributed load.

What is the orbit diameter of the shaker?

With a 20 mm orbit diameter, the shaker offers a mild yet efficient mixing action.

What kind of platform attachments are compatible?

The unit comes with a universal platform compatible with flask clamps, tube racks, and other attachments available separately.

How do I clean and maintain the shaker?

Clean the platform and outside with a gentle cloth and a mild detergent. Steer clear of aggressive solvents and chemicals.