CACTUS PSLC-295S Series Industrial 3D SSD

Introduction to Cactus Technologies

Industrial 3D pSLC -295S Series SSD Products

Features:

- Solid state design with no moving parts

- Available in industry standard 2.5” 7mm form factor

- Capacities from 32GB to 512GB

- True psuedo SLC mode operation

- Compliant with Serial ATA 3.4 specifications

- ATA-8 ACS2 command set compatible

- Supports Serial ATA Generation I/II transfer rate of 1.5/3.0/6.0 Gbps

- Supports ATA SMART Feature Set

- Supports ATA Security Feature Set

- Supports Data Set Management (TRIM)

- Supports SATA Partial/Slumber/DevSLP

- Advanced LDPC ECC

- Enhanced error correction, < 1 error in 1014 bits read

- Voltage support: 5.0V±10%

Cactus Technologies® Industrial 3D pSLC SSD is a high capacity solid-state flash memory product that complies with the Serial ATA 3.4 standard and is functionally compatible with a SATA hard disk drive. Cactus Technologies® Industrial 3D pSLC SSD provides up to 512GB offormatted storage capacity.

Cactus Technologies® Industrial 3D pSLC SSD product uses high quality Industrial Grade 3D SLC NAND flash memory (gTLC) from Kioxia Corporation operating in true psuedo SLC mode. In addition, it includes an on-drive intelligent controller that manages interface protocols, data storage and retrieval as well as ECC, defect handling and diagnostics, power management, and clock control. The controller’s firmware is upgradeable, thus allowing feature enhancements and firmware updates while keeping the BOM stable.

Supported Standards

Cactus Technologies® Industrial 3D pSLC SSD is fully compatible with the following specifications:

- ATA 8/ACS2 Specification published by ANSI

- Serial ATA 3.4 Specification published by the Serial ATA International Organization

Product Features

Cactus Technologies® Industrial 3D pSLC SSD contains a high-level, intelligent controller. This intelligent controller provides many capabilities, including the following:

- Standard ATA register and command set (same as found on most magnetic disk drives).

- Manages details of erasing and programming flash memory independent of the host system

- Sophisticated defect managing capabilities (similar to magnetic disk drives).

- Sophisticated system for error recovery using powerful error correction code (ECC).

- Intelligent power management for low power operation.

Host and Technology Independence

Cactus Technologies® Industrial 3D pSLC SSD appears as a standard SATA disk drive to the host system. The drive utilizes a 512-byte sector which is the same as that in an IDE magnetic disk drive. To write or read a sector (or multiple sectors), the host computer software simply issues an ATA Read or Write command to the drive as per the SATA protocol.

The host software then waits for the command to complete. The host system does not get involved in the details of how the flash memory is erased, programmed or read as this is all managed by the built-in controller in the drive.

Also, with the intelligent on-board controller, the host system software will not require changing as new flash memory evolves. Thus, systems that support the Cactus Technologies® Industrial 3D pSLC SSD products today will continue to work with future Cactus Technologies® Industrial 3D pSLC SSDs built with new flash technology without having to update or change host software.

Defect and Error Management

Cactus Technologies® Industrial 3D pSLC SSD contains a sophisticated defect and error management system similar to those found in magnetic disk drives. The defect management is completely transparent to the host and does not consume any user data space.

The soft error rate for Cactus Technologies® Industrial 3D pSLC SSD is much lower than that of magnetic disk drives. In the extremely rare case where a read error does occur, the drive has sophisticated ECC to recover the data.

These defect and error management systems, coupled with the solid-state construction, give Cactus Technologies® Industrial 3D pSLC SSDs unparalleled reliability.

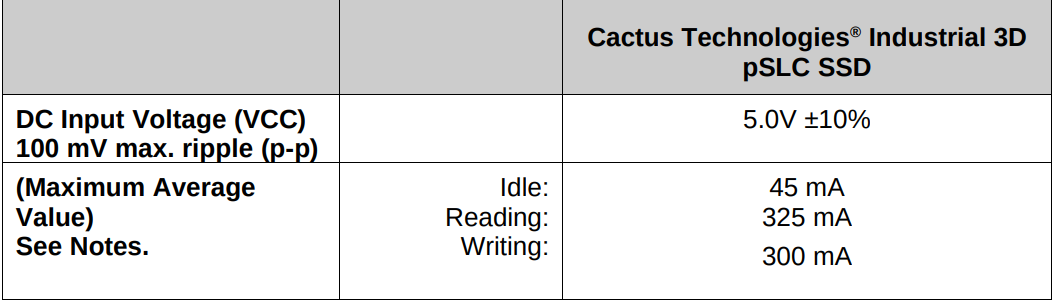

Power Supply Requirements

Cactus Technologies® Industrial 3D pSLC SSD operates at a voltage range of 5.0 volts ± 10%.

Product Specifications

For all the following specifications, values are defined at ambient temperature and nominal supply voltage unless otherwise stated.

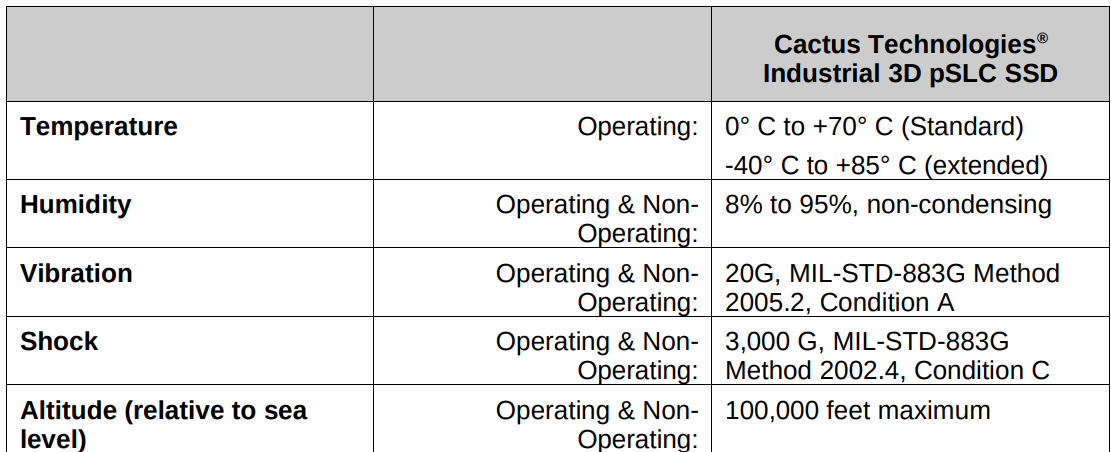

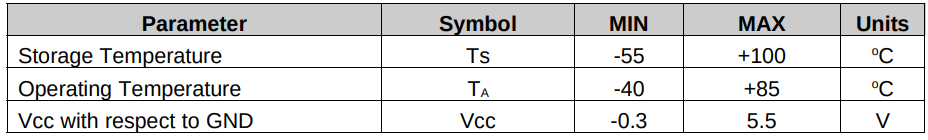

System Environmental Specifications

Table 2-1. Environmental Specifications

System Power Requirements

Table 2-2. Power Requirements

NOTES: All values quoted are typical at ambient temperature and nominal supply voltage unless otherwise stated. Sleep mode is specified under the condition that all drive inputs are static CMOS levels and in a “Not Busy“ operating state.

System Performance

All performance timings assume the drive controller is in the default (i.e., fastest) mode.

Table 2-3. Performance

- Read Transfer Rate Up to 550MBytes/sec

- Write Transfer Rate Up to 510 MBytes/sec

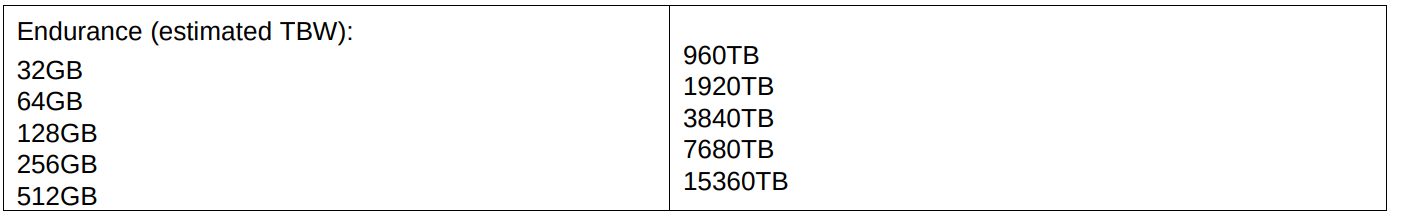

System Reliability

Table 2-4. Reliability

Note: estimated TBW assumes workload consisting of mostly large block writes; data-retention effects are

not considered.

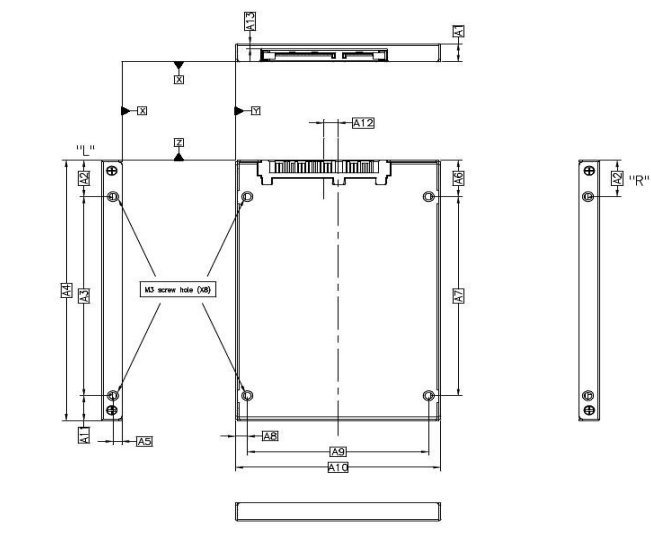

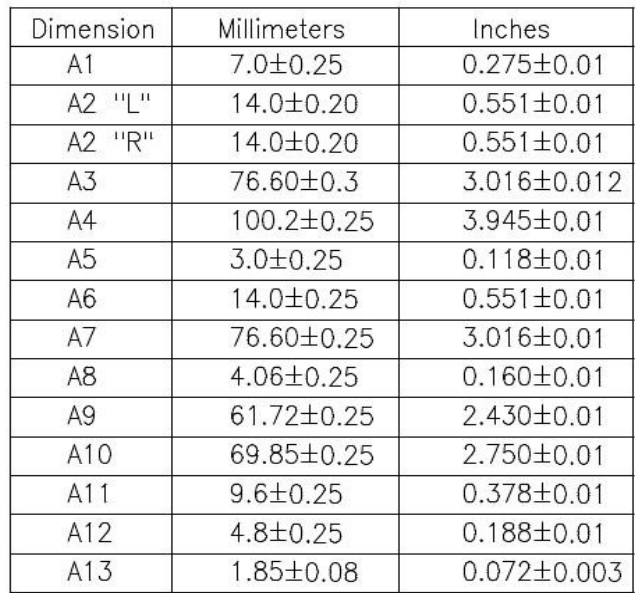

Physical Specifications

The following sections provide the physical specifications for Cactus Technologies® Industrial 3D pSLC SSD products.

2.5” SSD Physical Specifications

Figure 2-1. 2.5” SSD Dimensions

Interface Description

The following sections provide detailed information on the Cactus Technologies® Industrial 3D pSLC SSD interface.

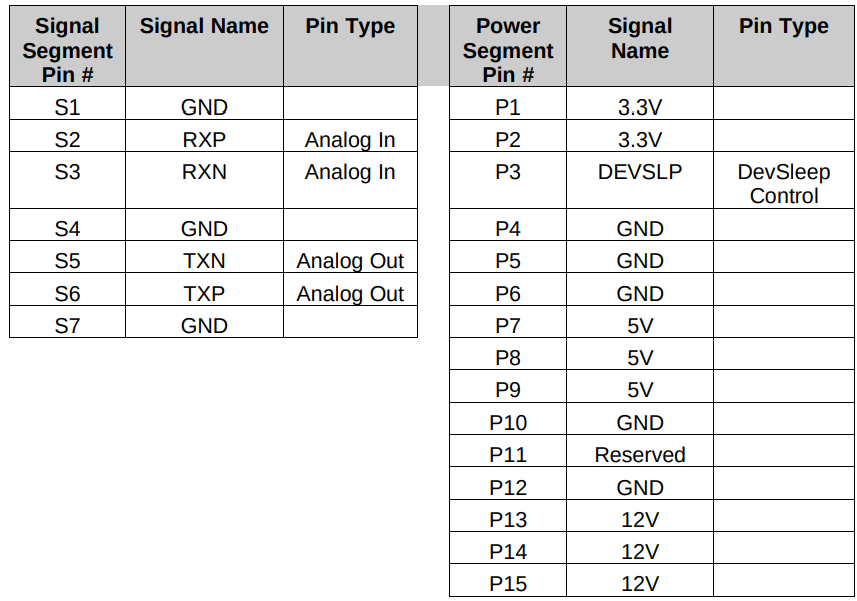

SSD Pin Assignments and Pin Type

Cactus Technologies® SSD uses industry standard 7+12 SATA connector. The signal/pin assignments and descriptions are listed in Table 3-5.

Table 3-5. SSD Pin Assignments and Pin Type

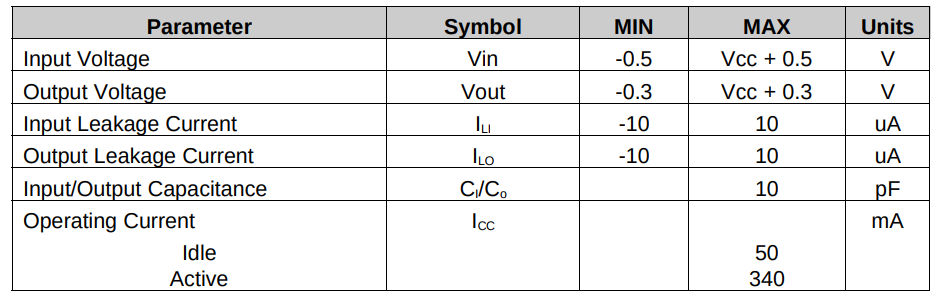

Electrical Specifications

The following table defines all D.C. Characteristics for the SSD products. Unless otherwise stated, conditions are:

Vcc = 5.0V ± 10%

Ta = -40°C to 85°C

Absolute Maximum Ratings

DC Characteristics

AC Characteristics

Cactus Technologies® SSD products conforms to all AC timing requirements as specified in the SATA-IO specifications. Please refer to that document for details of AC timing for all operation modes of the device.

ATA Drive Register Set Definition and Protocol

The communication to or from the SSD is done using FIS. Legacy ATA protocol is supported by using the legacy mode defined in the SATA specifications. In this mode, the FIS has defined fields which provide all the necessary ATA task file registers for control and status information. The Serial ATA interface does not support Primary/Secondary or Master/Slave configurations. Each SATA channel supports only one SATA device, with the register selection as defined by the ATA standard.

ATA Task File Definitions

The following sections describe the usage of the ATA task file registers. Note that the Alternate Status Register of legacy ATA is not defined for SATA drives.

Data Register

The Data Register is a 16-bit register, and it is used to transfer data blocks between the SSD data buffer and the Host.

Error Register

This register contains additional information about the source of an error when an error is indicated in bit 0 of the Status register. The bits are defined as follows:

![]()

- Bit 7 (BBK) This bit is set when a Bad Block is detected.

- Bit 6 (UNC) This bit is set when an Uncorrectable Error is encountered.

- Bit 5 This bit is 0.

- Bit 4 (IDNF) The requested sector ID is in error or cannot be found.

- Bit 3 This bit is 0.

- Bit 2 (Abort) This bit is set if the command has been aborted because of a status condition: (Not Ready, Write Fault, etc.) or when an invalid command has been issued.

- Bit 1 This bit is 0.

- Bit 0 (AMNF) This bit is set in case of a general error.

Feature Register

This register provides information regarding features of the SSD that the host can utilize.

Sector Count Register

This register contains the number of sectors of data requested to be transferred on a read or

write operation between the host and the SSD. If the value in this register is zero, a count of

256 sectors is specified. If the command was successful, this register is zero at command

completion. If not successfully completed, the register contains the number of sectors that

need to be transferred in order to complete the request.

Sector Number (LBA 7-0) Register

This register contains the starting sector number or bits 7-0 of the Logical Block Address (LBA) for any SSD data access for the subsequent command.

Cylinder Low (LBA 15-8) Register

This register contains the low order 8 bits of the starting cylinder address or bits 15-8 of the Logical Block Address.

Cylinder High (LBA 23-16) Register

This register contains the high order bits of the starting cylinder address or bits 23-16 of the Logical Block Address.

Drive/Head (LBA 27-24) Register

The Drive/Head register is used to select the drive and head. It is also used to select LBA addressing instead of cylinder/head/sector addressing. The bits are defined as follows:

![]()

- Bit 7 This bit is set to 1.

- Bit 6 LBA is a flag to select either Cylinder/Head/Sector (CHS) or Logical Block Address Mode (LBA). When LBA=0, Cylinder/Head/Sector mode is selected. When LBA=1, Logical Block Address is selected. In Logical Block Mode, the Logical Block Address is interpreted as follows:

- LBA07-LBA00: Sector Number Register D7-D0.

- LBA15-LBA08: Cylinder Low Register D7-D0.

- LBA23-LBA16: Cylinder High Register D7-D0.

- LBA27-LBA24: Drive/Head Register bits HS3-HS0.

- Bit 5 This bit is set to 1.

- Bit 4 (DRV) DRV is the drive number. This should always be set to 0.

- Bit 3 (HS3) When operating in the Cylinder, Head, Sector mode, this is bit 3 of the head number. It is Bit 27 in the Logical Block Address mode.

- Bit 2 (HS2) When operating in the Cylinder, Head, Sector mode, this is bit 2 of the head number. It is Bit 26 in the Logical Block Address mode.

- Bit 1 (HS1) When operating in the Cylinder, Head, Sector mode, this is bit 1 of the head number. Itis Bit 25 in the Logical Block Address mode.

- Bit 0 (HS0) When operating in the Cylinder, Head, Sector mode, this is bit 0 of the head number. It

is Bit 24 in the Logical Block Address mode.

Status Registers

These registers return the status when read by the host. Reading the Status register does clear a pending interrupt while reading the Auxiliary Status register does not. The meaning of the status bits are described as follows:![]()

- Bit 7 (BUSY) The busy bit is set when the device has access to the command buffer and registers

and the host is locked out from accessing the command register and buffer. No other

bits in this register are valid when this bit is set to a 1. - Bit 6 (RDY) RDY indicates whether the device is capable of performing operations requested by

the host. This bit is cleared at power up and remains cleared until the device is ready

to accept a command. - Bit 5 (DWF) This bit, if set, indicates a write fault has occurred.

- Bit 4 (DSC) This bit is set when the device is ready.

- Bit 3 (DRQ) The Data Request is set when the device requires that information be transferred

either to or from the host through the Data register. - Bit 2 (CORR) This bit is set when a Correctable data error has been encountered and the data has

been corrected. This condition does not terminate a multi-sector read operation. - Bit 1 (IDX) This bit is always set to 0.

- Bit 0 (ERR) This bit is set when the previous command has ended in some type of error. The bits in

the Error register contain additional information describing the error.

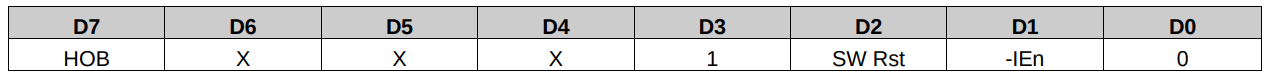

Device Control Register

This register is used to control the drive interrupt request and to issue an ATA soft reset to the drive. The bits are defined as follows:

Bit 7 This bit is used in 48-bit addressing mode. When cleared, the host can read the most recently

written values of the Sector Count,Drive/Head and LBA registers. When set, the host will read

the previous written values of these registers. A write to CACTUS PSLC-295S Series Industrial 3D SSD any Command block register will

clear this bit.

Bit 6 This bit is an X (Do not care).

Bit 5 This bit is an X (Do not care).

Bit 4 This bit is an X (Do not care).

Bit 3 This bit is ignored by the drive.

Bit 2 (SW Rst)This bit is set to 1 in order to force the drive to perform an AT Disk controller Soft

Reset operation. The drive remains in Reset until this bit is reset to ‘0’.

Bit 1 (-IEn) The Interrupt Enable bit enables interrupts when the bit is 0. When the bit is 1, interrupts from the drive are disabled. This bit is set to 0 at power on and Reset.

Bit 0 This bit is ignored by the drive.

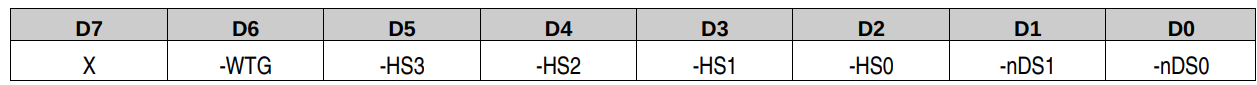

Drive Address Register

This register is provided for compatibility with the AT disk drive interface. It is recommended that this register not be mapped into the host’s I/O space because of potential conflicts on Bit 7. The bits are defined as follows:

Bit 7 This bit is unknown.

Implementation Note:

Conflicts may occur on the host data bus when this bit is provided by a Floppy Disk Controller

operating at the same addresses as the SSD. Following are some possible solutions to

this problem:

- Locate the SSD at a non-conflicting address (i.e., Secondary address (377) when a Floppy

Disk Controller is located at the Primary addresses). - Do not install a Floppy and a SSD in the system at the same time.

- Implement a socket adapter that can be programmed to (conditionally) tri-state D7 of I/0

address 3F7/377 when a SSD product is installed and conversely to tri-state D6-D0 of

I/O address 3F7/377 when a floppy controller is installed. - Do not use the SSD’s Drive Address register. This may be accomplished by either a) If

possible, program the host adapter to enable only I/O addresses 1F0-1F7, 3F6 (or 170-

177, 176) to the SSD or b) if provided use an additional Primary/Secondary

configuration in the SSD that does not respond to accesses to I/O locations 3F7 and

377. With either of these implementations, the host software must not attempt to use

information in the Drive Address Register.

Bit 6 (-WTG) This bit is 0 when a write operation is in progress, otherwise, it is 1.

Bit 5 (-HS3) This bit is the negation of bit 3 in the Drive/Head register.

Bit 4 (-HS2) This bit is the negation of bit 2 in the Drive/Head register.

Bit 3 (-HS1) This bit is the negation of bit 1 in the Drive/Head register.

Bit 2 (-HS0) This bit is the negation of bit 0 in the Drive/Head register.

Bit 1 (-nDS1) This bit is 0 when drive 1 is active and selected.

Bit 0 (-nDS0) This bit is 0 when the drive 0 is active and selected

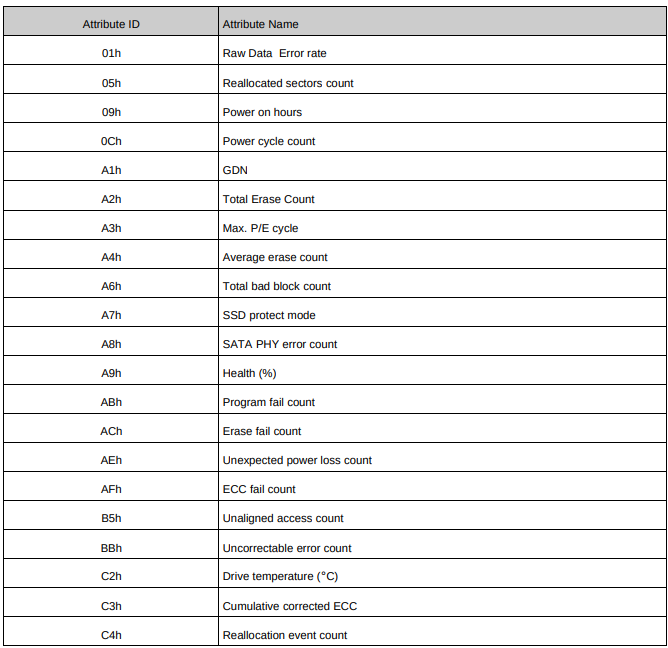

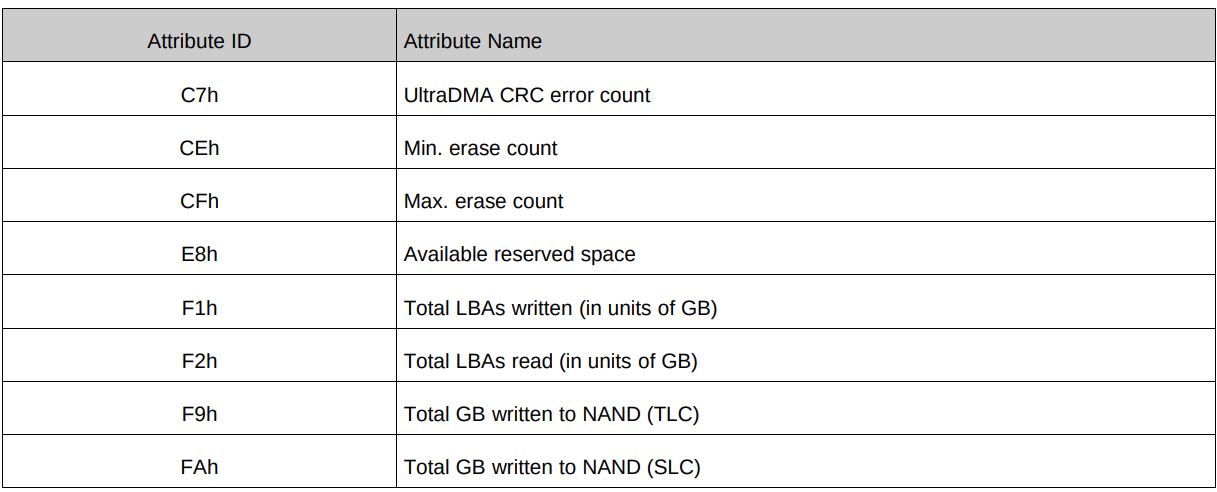

S.M.A.R.T. Feature Set

Cactus Technologies® -295S Series SSDs supports S.M.A.R.T. attribute reporting. The reported attributes are listed below.

S.M.A.R.T Attributes

The following table lists the attributes returned in bytes 2-361 of the 512-byte SMART data.

Each attribute occupies 12 bytes of data. Byte 0 is Attribute ID, bytes 1-2 are status flags,bytes 3-4 are reserved bytes; the table below shows the definitions of bytes 5-11:

Appendix A. Ordering Information

Model KDXFI-295S

Where: X is drive capacities:

32G ———— 32GB

64G ———— 64GB

128G ———- 128GB

256G ———– 256GB

512G ———— 512GB

Where: I is temperature grade

blank ———— standard

I ———— extended

Example:

(1) 128GB 2.5” SSD ———————————————————- KD128GF-295S

(2) 128GB 2.5” SSD extended temp. ———————————– KD128GFI-295S

Appendix Technical Support Services

B.1.Direct Cactus Technologies® Technical Support

Email: tech@cactus-tech.com

Appendix C.Cactus Technologies® Worldwide Sales Offices

Email: sales@cactus-tech.com

Email: americas@cactus-tech.com

Appendix D.Limited Warranty

WARRANTY STATEMENT

Cactus Technologies® warrants its Industrial 3D pSLC products only to be free of any defects in materials or workmanship that would prevent them from functioning properly for CACTUS PSLC-295S Series Industrial 3D SSD two years from the date of purchase or when rated TBW is exceeded, whichever occurs first. This express warranty is extended by Cactus Technologies® Limited to customers of our products.

GENERAL PROVISIONS

This warranty sets forth the full extent of Cactus Technologies® responsibilities regarding the Cactus Technologies® Industrial 3D pSLC Flash Storage Products. Cactus Technologies®, at its sole option, will repair, replace or refund the purchase price of the defective CACTUS PSLC-295S Series Industrial 3D SSD product. Cactus Technologies® guarantees our products meet all specifications detailed in our product manuals. Although Cactus Technologies® products are designed to withstand harsh environments and have the highest specifications in the industry, they are not warranted to never have failure and Cactus Technologies® does not warranty against incidental or consequential damages. Accordingly, in any use of products in life support systems or other applications where failure could cause injury or loss of life, the products should only be incorporated in systems designed with appropriate redundancy, fault tolerant or backup features.

WHAT THIS WARRANTY COVERS

For products found to be defective, Cactus Technologies® will have the option of repairing, replacing or refunding the purchase price the defective product, if the CACTUS PSLC-295S Series Industrial 3D SSD following conditions are met: A. The defective product is returned to Cactus Technologies® for failure analysis as soon as possible after the failure occurs. B. An incident card filled out by the user, explaining the conditions of usage and the nature of the failure, accompanies each returned defective product. C.

No evidence is found of abuse or operation of products not in accordance with the published specifications, or of exceeding maximum ratings or operating conditions. All failing products returned to Cactus Technologies® under the provisions of this limited warranty shall be tested to the product’s functional and performance specifications.

Upon confirmation of failure, each product will be analyzed, by whatever means necessary, to determine the root cause of failure. If the root cause of failure is found to be not covered by the above provisions, then the product will be returned to the customer with a report indicating why the failure was not covered under the warranty. This warranty does not cover defects, malfunctions, performance failures or damages to the unit resulting from use in other than its normal and customary manner, misuse, accident or neglect; or improper alterations or repairs.

Cactus Technologies® Limited may repair or replace, CACTUS PSLC-295S Series Industrial 3D SSD at its discretion, any product returned by its customers, even if such product is not covered under warranty, but is under no obligation to do so.

RECEIVING WARRANTY SERVICE

According to Cactus Technologies® warranty procedure, defective product should be returned only with prior authorization from Cactus Technologies® Limited. Please contact Cactus Technologies® Customer Service department (tech@cactus-tech.com) with the following information: product model number and description, nature of defect, conditions of use, proof of purchase and purchase date. If approved, Cactus Technologies® will issue a Return Material Authorization or Product Repair Authorization number with shipping instructions

FAQs

What type of SSD is the PSLC-295S Series?

The PSLC-295S is a 2.5″ SATA III solid state drive of industrial quality that makes use of 3D NAND flash technology based on pseudo single-level cell (pSLC) technology. It provides improved endurance, dependability, and performance in difficult situations because it is designed for tough applications.

What interface does the SSD use?

It is backward compatible with SATA II (3Gbps) and SATA I (1.5Gbps) ports and utilises a SATA III 6Gbps interface.

What is pSLC, and how is it different from standard TLC or MLC?

Using TLC or MLC technology, pSLC (Pseudo-Single Level Cell) is a NAND arrangement that stores one bit per cell. This makes it perfect for industrial application where data integrity is crucial since it increases write endurance, data retention, and dependability.

Do I need to install drivers to use the SSD?

No particular drivers are required. The drive is plug-and-play compatible with the majority of contemporary operating systems, such as Windows, Linux, and embedded systems, that support SATA storage devices.

Does the SSD include power loss protection (PLP)?

Indeed. To guarantee data integrity in the case of an unexpected power outage during write operations, the PSLC-295S series is equipped with Power Loss Protection (PLP). Verify that your particular model variant supports PLP.

What is the write endurance of this SSD?

The drive’s endurance is far higher than that of typical TLC/MLC SSDs because of pSLC technology; depending on the model and capacity, it can frequently surpass 30,000 to 100,000 program/erase cycles per block.