Clarke CECS405D Electric Chainsaw

Introduction

Thank you for purchasing this Electric Chainsaw. Please read this manual thoroughly before attempting to operate, and carefully follow all instructions given. It is vitally important that ALL precautions are taken, as specified, which will not only provide protection for yourself and that of others around you, but will also ensure that the chainsaw will give you long and satisfactory service.

Safety Instructions

- Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges, or refrigerators.

- DO NOT expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

- Avoid accidental starting. Ensure the switch is in the off position before connecting to the power supply.

- DO NOT overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

- Dress properly. DO NOT wear loose clothing or jewellery. Keep your hair, clothing, and gloves away from moving parts.

- Disconnect the power before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of accidentally starting the power tool.

- Store idle tools out of the reach of children and DO NOT allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

- Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use.

- Keep all parts of the body away from the saw chain when the chainsaw is operating. Before you start the chainsaw, make sure the saw chain is not contacting anything.

- A moment of inattention while operating chainsaws may cause entanglement of your clothing or body with the saw chain.

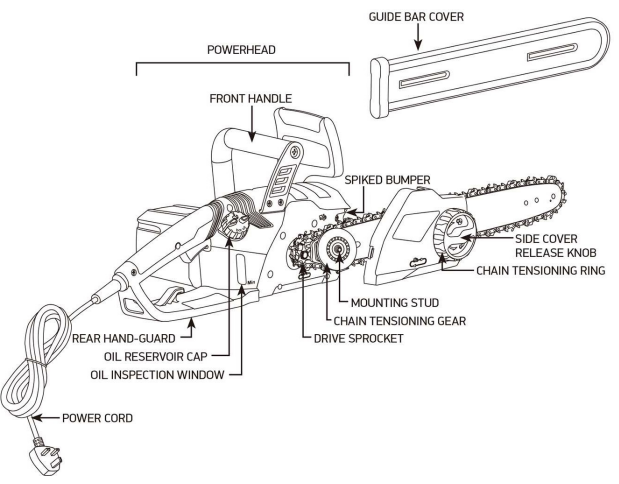

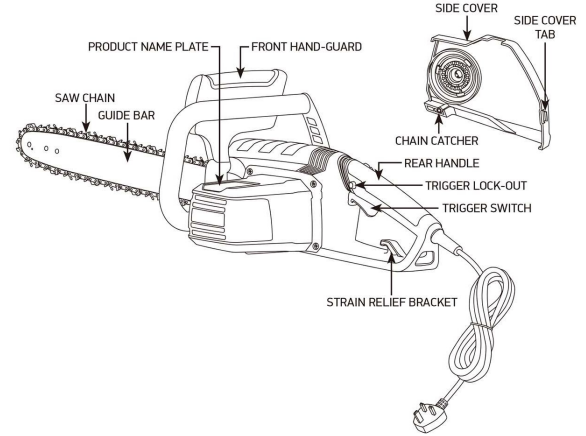

Overview

Names & Terms

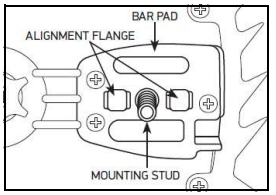

- Alignment Flange

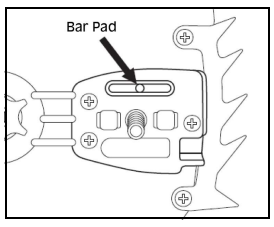

The protrusion on the bar pad that fits into the bar slot. - Automatic Oiler

The system that automatically lubricates the guide bar and saw chain. - Bar Pad

The mounting pad on the powerhead helps ensure proper alignment of the guide bar. - Bar Slot

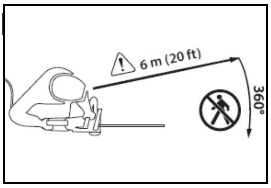

The cut-out portion of the guide bar that fits onto the alignment flange and mounting stud. - Bystander Safety Zone

A 6m (20ft) circle around the operator that must remain free from bystanders, children, and pets. - Chain Brake

A device for stopping or locking the saw chain, activated manually or non-manually when kickback occurs. - Chain Catcher

A device for retaining the saw chain if it breaks or derails. - Chain Gauge

The thickness of the saw chain drive link, where it fits into the bar groove, is indicated by the part number stamped on the drive links. - Chain Pitch

The distance between any three consecutive rivets on the saw chain, divided by two, is indicated by the part number stamped on the drive links. - Chainsaw Powerhead

A chainsaw without the saw chain or guide bar. - Chain Tensioning Gear

A gear mounted on the guide bar that adjusts saw chain tension when rotated. - Chain Tensioning Ring

The ring around the side cover release knob, which, when turned, adjusts the saw chain tension.

Preparing Fo Use

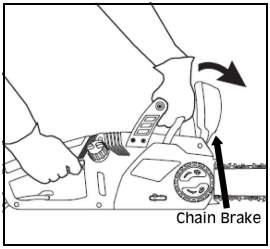

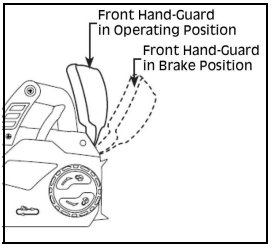

After unpacking the chainsaw, check the position of the front hand-guard. The chainsaw will not run with the chain brake engaged. Pull the front hand-guard back and forward the front handle before operation, as shown.

Filling the bar

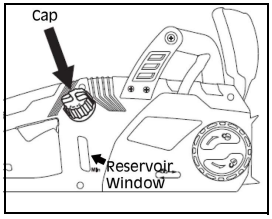

- Place the chainsaw on a firm, flat surface so that the oil cap is on top, as shown.

- Clean any debris from the cap area.

- Remove the cap.

- Carefully pour the bar and chain oil into the reservoir.

- Replace the cap and make sure oil is visible in the reservoir window.

Priming the Oiler

- Unplug the chainsaw.

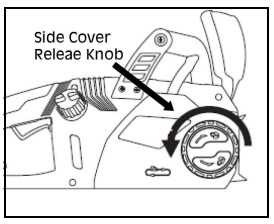

- Loosen the side cover release knob slightly, but DO NOT remove the side cover.

- Loosen the chain tensioning ring that is on the outside of the side cover release knob (turn it anti-clockwise) as far as it will go.

- Loosen the side cover release knob and remove the side cover.

- Remove the guide bar and saw chain.

- Install the side cover, then lightly tighten the side cover release knob.

- Plug in the chainsaw.

- Run the chainsaw for about two minutes.

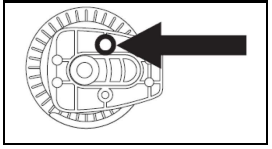

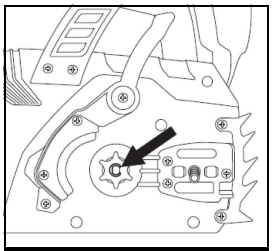

- Unplug the chainsaw, remove the side cover, and check for oil on the bar pad, as shown.

- If no oil is present on the bar pad, replace the side cover and run for another 30 seconds.

- When oil begins to seep from the hole, unplug the chainsaw and replace the bar and chain as described in the next section, ‘Assembling the Guide Bar and Saw Chain’.

Assembly

- Unplug the chainsaw.

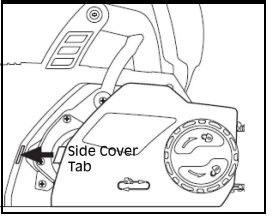

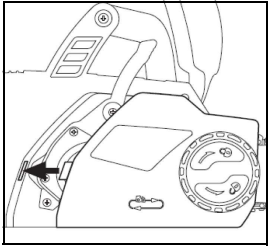

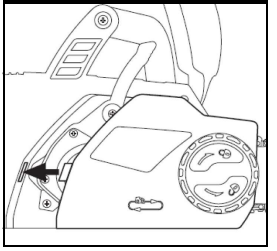

- Loosen the side cover release knob by turning it counterclockwise, as shown, then remove the side cover.

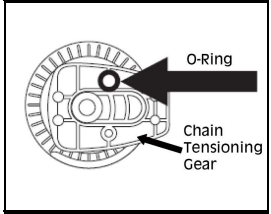

- There is a rubber O-ring that is important to the function of the saw, as shown. The rubber O-ring must be in place around the pin on the tensioner before the tensioner is screwed onto the bar.

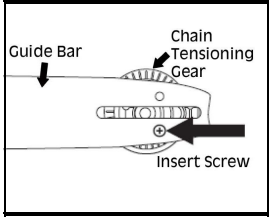

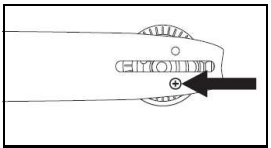

- Insert the screw from the back side of the chain tensioning gear and attach the chain tensioning gear to the guide bar, as shown.

- Place the chain tensioning gear on the side of the guide bar facing you such that the rectangular piece does not protrude past the edges of the guide bar, and insert the screw.

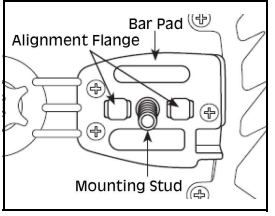

- Place the guide bar on the bar pad by sliding the bar slot over the alignment flange, as shown, with the mounting stud inserted through the hole in the chain tensioning gear.

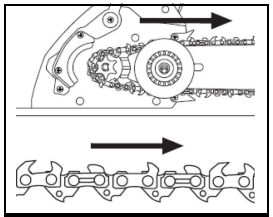

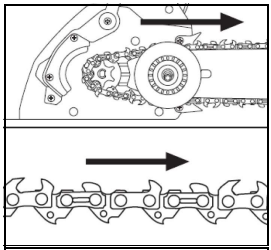

- Loop the new saw chain onto the drive sprocket so that the cutting edge of the teeth along the top of the bar face away from the powerhead, as shown.

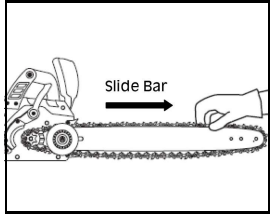

- Feed the chain into the groove of the bar and slide the bar away from the motor to remove slack from the chain, as shown.

- Install the side cover, making sure the chain catcher and side cover tab are seated in their proper locations, as shown, then lightly tighten the side cover release knob.

- Tension the chain as described in the following section ‘Tensioning the Saw Chain’.

Tensioning the Saw

- Unplug the chainsaw before tensioning.

- Loosen the side cover release knob slightly, but DO NOT remove the side cover.

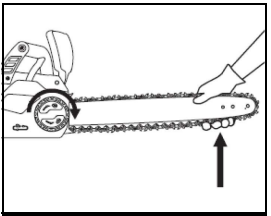

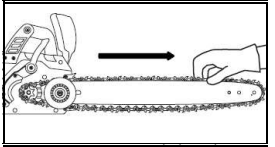

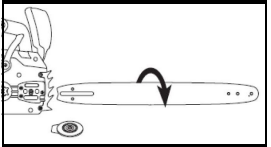

- Hold up the nose of the guide bar, as shown, and turn the chain tensioning ring clockwise.

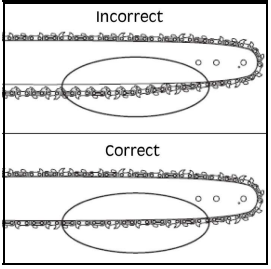

- Tighten the chain tensioning ring until the lowest cutters underneath the bar solidly contact the bar, as shown.

- Tighten the side cover release knob.

- Lightly pull on the chain. The tension is correct when the chain snaps back after being pulled 3mm away from the guide bar.

- After a short period of use, allow the chain to cool, unplug the chainsaw, and check the tension again. Watch tension carefully for the first half hour of use and periodically throughout the life of the chain, readjusting as required when the chain and bar are cool to the touch. NEVER tension the chain when it is hot.

Using the Chainsaw

For ‘first-time’ users of this type of product, we recommend that introductory training be undertaken from an experienced person before use.

Personal Protective Equipment

The following Personal Protective Equipment (PPE) available from your local CLARKE dealer has been designed for use with chainsaws.

- A safety helmet with a mesh visor.

- Ear defenders.

- Specialist chainsaw gloves.

- Trousers or chaps suitable for chainsaw use (they contain a clogging material which stops the chain if cut).

- Safety boots with toe and shin protection.

- Close-fitting hi-visibility jacket.

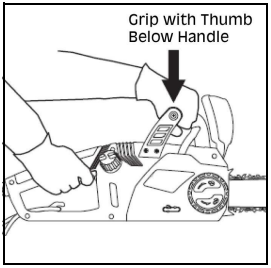

Grip

Always grip the tool with both hands. Grasp the front handle with the left hand and the rear handle with the right, as shown. Wrap the fingers over the top of the handle with the thumb below the handle.

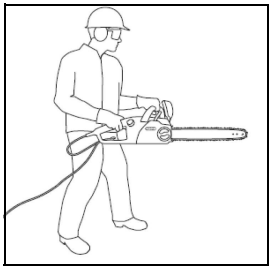

Footing

Stand with both feet on solid ground with weight evenly spread between them, as shown.

Starting the Chainsaw

- Make sure the chain brake is not engaged.

- Grasp the front and rear handles firmly.

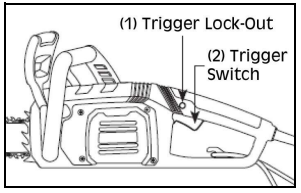

- Press and hold the trigger lockout with the thumb (1).

- To start the saw, squeeze the trigger switch (2), as shown.

- There is no need to continue to press the trigger lockout. It will remain disengaged until the trigger is released.

Stopping the Chainsaw

Release the trigger switch to stop the chainsaw.

Testing the Brake

To check brake operation

- Place the saw on a firm, flat surface with no obstructions to the chain.

- Start the saw briefly.

- Keep the left hand on the front handle and roll the left wrist to move the front hand guard forward to manually activate the chain brake, as shown.

- Release the trigger switch.

- Return the front hand guard to operating position.

Power Cord

- Specifically labeled for outdoor use.

- Of a wire size heavy enough to carry the current the full length of the cable, according to the table below.

Select the gauge of extension cord based on the desired length and the electrical specifications found on the product label or in the specification section of this manual.

Cord Length (M) & Min. Diameter Wire Size

- 0 – 15: 1.6277mm

- 16 – 30: 2.0525mm

Make sure the insulation is free of cracks and that the plugs are undamaged.

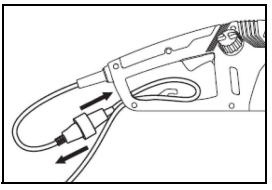

Using the Strain Relief

It is important to use the strain relief bracket for two reasons

- It saves wear on both the power cord and the extension cord and their plugs.

- It prevents the chainsaw frog from unplugging from the extension cord.

To use the strain relief bracket, bend the extension cord into a U shape and put it through the hole in the rear handle. Slide the loop of cord over the hook and tug lightly until snug, as shown.

Cutting, Pruning, Felling, Limbing, and Bucking

Practice cutting logs on a sawhorse or cradle until you become comfortable operating the saw. To get the best performance and to operate the saw safely, follow these instructions.

- Observe all applicable national and local rules and regulations for cutting.

- Take frequent breaks to reduce the risk of injury.

- Before beginning to cut, make sure the saw chain is properly tensioned and the chain is sharp.

- The pressure required to make cuts increases noticeably.

- Wood chips coming off the chain are very fine or dust-like.

- Assume the proper cutting grip and stance in front of the wood with the saw turned off. Press the trigger switch. Let the chain reach full speed before beginning the cut.

- Begin cutting by lightly pressing the guide bar against the wood. Use only light pressure and let the saw do the work.

- Maintain a steady speed throughout the cut, releasing pressure just before the end of the cut.

- Know the location of the cord at all times to avoid trip hazards and avoid cutting the cord.

- Know the location of the tip of the bar at all times and avoid contact with other objects.

- If the saw stops suddenly when cutting, remove the saw from the cut, then resume cutting using lighter pressure on the workpiece.

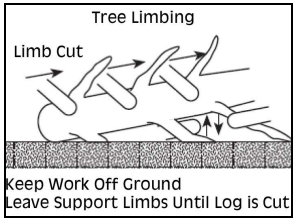

Limbing A Tree

Limbing is removing the branches from a fallen tree.

- When limbing, leave large lower limbs to support the log off the ground.

- Remove the small limbs in one cut.

- Branches under tension should be cut from the bottom up to avoid binding the chainsaw, as shown.

Bucking A Log

Bucking is cutting a log into lengths. It is important to make sure the footing is firm and the weight is evenly distributed on both feet. When possible, the log should be raised and supported by the use of limbs, logs, or chocks.

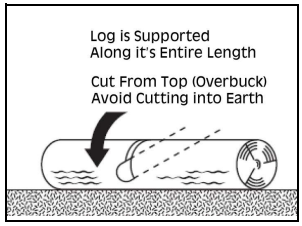

- When the log is supported along its entire length, cut from the top (overbuck), as shown.

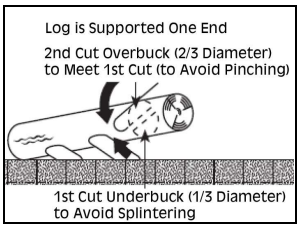

- When the log is supported on one end, cut 1/3 the diameter from the underside (underbuck), then make the finished cut by overbucking to meet the first cut, as shown.

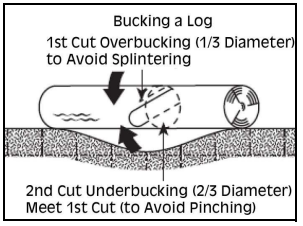

- When the log is supported on both ends, cut 1/3 of that diameter from the top overbuck, then make the finished cut by underbucking the lower 2/3 to meet the first cut, as shown.

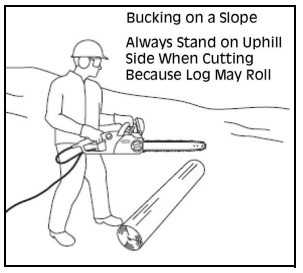

- When bucking on a slope, always stand on the uphill side of the log, as shown.

- Don’t let the chain contact the ground.

- After completing the cut, wait for the saw chain to stop before you move the chainsaw.

- Always stop the motor before moving from tree to tree.

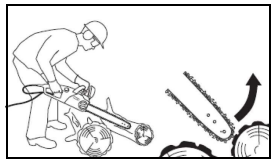

Prevention Of Kickback

- Maintain a firm grip, with thumbs and fingers encircling the chainsaw handles, with both hands on the saw, and position your body and arm to allow you to resist kickback forces. Kickback forces can be controlled by the operator if proper precautions are taken. DO NOT let go of the chainsaw.

- DO NOT overreach and DO NOT cut above shoulder height. This helps prevent unintended tip contact and enables better control of the chainsaw in unexpected situations.

- Only use replacement bars and chains specified by the manufacturer. Incorrect replacement bars and chains may cause chain breakage and/ or kickback.

Kickback Safety

- Chain Brake. This chainsaw comes equipped with a chain brake, which stops both the motor and the motion of the chain when kickback occurs. The chain brake can be activated by the forward motion of the front hand-guard as the saw rotates backward during kickback; it can also be activated by the inertial forces generated from a kickback event.

- Chain. This chainsaw comes equipped with a saw chain that meets the reduced kickback performance requirements of ISO 9518.

- Bar. This saw comes equipped with a reduced kickback guide bar that has a small radius nose. Smaller radius noses have less potential for kickback..

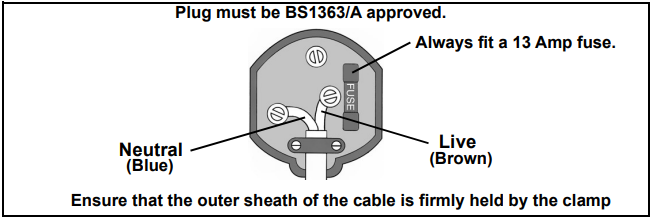

Electrical Connections

- The Blue wire must be connected to the terminal which is marked N or coloured Black.

- The Brown wire must be connected to the terminal which is marked L or coloured Red.

- We strongly recommend that this machine be connected to the mains supply via a Residual Current Device (RCD). If in any doubt, consult a qualified electrician. DO NOT attempt any repairs yourself.

Maintainance & Cleaning

- Cord

Ensure the plug is in good condition and not bent or corroded, and that the insulation is intact. If the cord is damaged, DO NOT USE. Contact the CLARKE parts/service department. - Handles

Front and rear handles should not have cracks or other damage. They should be clean and dry. - Front Hand Guard

The front hand guard should be free of damage and able to move easily back and forth. When moved, the front hand guard should activate the chain brake. - Guide Bar

The bar should be straight and free of chips, cracks, or excessive wear. - Saw Chain

The chain should be properly tensioned and sharp, and all components free of cracks, chips, broken teeth, or excessive wear. See ‘Tensioning the Saw Chain’ (pages 17-18) section. - Side Cover

The side cover should be free of cracks or other damage. It should fit tightly to the saw body with no warping. Make sure the chain catcher is free of cracks. - Chain Brake

Test the chain brake to make sure it is functioning properly. See the ‘Testing the chain brake’ section on page 21. - Oil Level

Make sure the oil reservoir is full before use. - Motor Housing

Check for cracks in the cover and debris in the air intake vents. - Drive Sprocket

Look for deep grooves, broken teeth, or burrs. Chain Tensioning Gear: Inspect the gear for cracks, chips, loose screws, warping, or other damage. - Bar Mounting Area Underneath Side Cover

Make sure the bar mounting stud is not bent, stripped, or cross-threaded, and that the bar pad and alignment flange are free of debris and intact.

Sharpening the Chainsaw

- A sharpener is designed specially for sharpening chainsaw chains. DO NOT use it for any other purpose.

- DO NOT sharpen damaged chainsaw chains.

- DO NOT operate the sharpener without the relevant protective covers in place.

- ALWAYS adhere to the sharpeners’ user instructions and safety precautions.

Cleaning

- Always wear gloves when cleaning the chainsaw.

- Unplug the chainsaw.

- Remove wood chips and other debris from the motor housing and the vents.

- Always clean out wood chips, sawdust, and dirt from the bar groove when replacing the chain.

- Make sure the cord and plug are dry before connecting to an outlet.

Replacing A Worn

- Always wear gloves when handling the saw chain.

- Unplug the chainsaw.

- Loosen the side cover release knob slightly, but DO NOT remove the side cover.

- Loosen the chain tensioning ring (turn it anti-clockwise) as far as it will go.

- Loosen the side cover release knob and remove the side cover.

- Remove the saw chain.

- Loop the new saw chain onto the drive sprocket so that the cutting edges of the teeth along the top of the bar face away from the powerhead, as shown.

- Feed the chain into the groove of the bar and slide the bar away from the motor to remove slack from the chain, as shown.

- Install the slide cover, making sure the chain catcher and side cover tab are seated in their proper locations, as shown, then lightly tighten the side cover release knob.

- Tension the chain as described in the ‘Tensioning the Saw Chain’ section on pages 17-18.

Maintaining the Guidebar

To even bar wear and maximise bar life, flip the bar occasionally.

- Always wear gloves when handling the saw chain and bar.

- Unplug the chainsaw.

- Loosen the side cover release knob slightly, but DO NOT remove the side cover.

- Loosen the chain tensioning ring (turn it anti-clockwise) as far as it will go.

- Loosen the side cover release knob and remove the side cover.

- Remove the bar and chain and inspect for damage and wear.

- Remove the screw from the back side of the chain tensioning gear and remove the chain tensioning gear from the guide bar, as shown.

- Flip the bar, as shown.

- There is a rubber washer that is important to the function of the saw. The rubber washer must be in place around the pin on the tensioner before the tensioner is screwed onto the bar, as shown.

- Place the chain tensioning gear on the side of the guide bar facing you such that the rectangular piece does not protrude past the edges of the guide bar, and replace the screw.

- Place the guide bar on the bar pad by sliding the Clarke CECS405D Electric Chainsaw bar slot over the alignment flange, as shown.

- Replace the saw chain as described in the ‘Replacing a Worn Saw Chain’ section on pages 31-32.

- Tension the chain as described in the ‘Tensioning the Saw Chain’ section on pages 17-18.

Replacing A Worn

- Always wear gloves when handling the saw chain and bar.

- Unplug the chainsaw.

- Loosen the side cover release knob slightly, but DO NOT Clarke CECS405D Electric Chainsaw remove the side cover.

- Loosen the chain tensioning ring (turn it anti-clockwise) as far as it will go.

- Loosen the side cover release knob and remove the side cover.

- Remove the bar and chain.

- Remove the screw from the back side of the chain tensioning gear and remove the chain tensioning gear from the guide bar as described in the ‘Maintaining the Guide Bar’ section on pages 32-33.

- Place the chain tensioning gear on the new guide bar and replace the screw.

- Replace the guide bar as described in the ‘Maintaining the Guide Bar’ section on pages 32-33.

- Replace the saw chain as described in the ‘Replacing a Worn Saw Chain’ section on pages 31-32.

- Tension the chain as described in the ‘Tensioning the Saw Chain’ section on pages 17-18.

Tension Gear

- Always wear gloves when handling the saw chain and bar.

- Unplug the chainsaw.

- Loosen the side cover release knob slightly, Clarke CECS405D Electric Chainsaw but DO NOT remove the side cover.

- Loosen the chain tensioning ring (turn it anti-clockwise) as far as it will go.

- Loosen the side cover release knob and remove the side cover.

- Remove the bar and chain.

- Remove the screw from the back side of the chain tensioning gear and remove the chain tensioning gear from the guide bar as described in the ‘Maintaining the Guide Bar’ section on pages 32-33.

- Place the new chain tensioning gear on the side of the guide bar facing you, and replace the screw.

- Place the guide bar on the bar pad by sliding the bar slot over the alignment flange as described in the ‘Maintaining the Guide Bar’ section on pages 32-33.

- Replace the saw chain as described in the ‘Replacing a Worn Saw Chain’ section on pages 31-32.

- Tension the chain as described in the ‘Tensioning the Clarke CECS405D Electric Chainsaw Saw Chain’ section on pages 17-18.

Drive Spocket

Replace the drive sprocket after every two saw chain replacements or when the sprocket is damaged.

- Always wear gloves when handling the saw chain and bar.

- Unplug the chainsaw.

- Loosen the side cover release knob slightly, but DO NOT remove the side cover.

- Loosen the chain tensioning ring (turn it anti-clockwise) as far as it will go.

- Loosen the side cover release knob and remove the side cover.

- Remove the bar and chain.

- Use a small flat screwdriver to pry open and remove the e-clip, then remove the drive sprocket and spring, as shown.

- Insert the new spring and drive sprocket, and install the new e-clip, as shown.

- Replace the saw chain as described in the ‘Replacing Clarke CECS405D Electric Chainsaw a Worn Saw Chain’ section on pages 31-32.

- Tension the chain as described in the ‘Tensioning the Saw Chain’ section on pages 17-18.

Storage & Transportation

- Switch the chainsaw off and disconnect it from Clarke CECS405D Electric Chainsaw the power supply.

- Clean the chainsaw as described on page 31.

- Store the chainsaw and its accessories in a dry, frost-free, well-ventilated place.

- Always store the chainsaw in a place that is inaccessible to children. The ideal storage temperature is between 10°C and 30°C.

- We recommend using the original package for storage or covering the chainsaw with a suitable cloth or enclosure to protect it against dust.

- Switch the chainsaw off and disconnect it from the power supply.

- Attach the blade cover.

- Always carry the chainsaw by its handles.

- Protect the chainsaw from any heavy impact or strong vibrations that may occur during transportation in vehicles.

- Secure the chainsaw to prevent it from slipping or falling over.

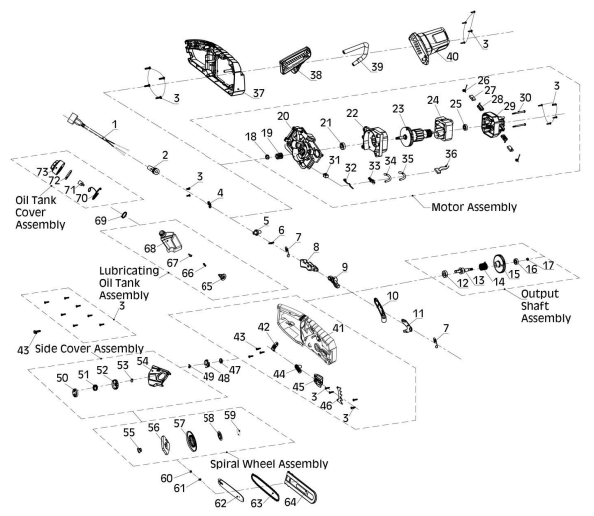

Exploded Diagram

Part List

| 1 | Power Cable Assembly | 32 | Brake Spring |

| 2 | Cable Sheath | 33 | Pump Unit |

| 3 | Screw ST4x16 | 34 | Oil Pipe |

| 4 | Cable Clamp | 35 | Oil Pipe |

| 5 | Button | 36 | Left Housing |

| 6 | Button Spring | 37 | Preventer Plate |

| 7 | Retracting Spring | 38 | Front Handle |

| 8 | Button | 39 | Motor Rear Cover |

| 9 | Intermediate Connecting Rod | 40 | Right Housing |

| 10 | Link Switch | 41 | Front Handle Support Plate |

| 11 | Brake Block | 42 | Trigger |

| 12 | Deep Groove Ball Bearing | 43 | Screw ST5 x 25 |

| 13 | Output Shaft | 44 | Seal Ring |

| 14 | Brake Torsion Spring | 45 | Thermal Insulation Gasket |

| 15 | Output Shaft Gear | 46 | Buffer Board |

| 16 | 608Z Bearing | 47 | Axle Sleeve |

| 17 | Screw M8 | 48 | Sprocket |

| 18 | Hexagon Nut M8 x 8 | 49 | E Ring |

| 19 | Pinion | 50 | Compression Knob |

| 20 | Mounting Plate | 51 | Press Knob Spring |

| 21 | 6000Z Bearing | 52 | Adjusting Knob |

| 22 | Wind Deflector | 53 | Circlip for Shaft |

| 23 | Rotor Assembly | 54 | Side Cover |

| 24 | Stator Assembly | 55 | Adapter Sleeve |

| 25 | 608 Bearing | 56 | Knockout Plate |

| 26 | Torsional Spring | 57 | Circling Round |

| 27 | Carbon Brush | 58 | Pressing Plate |

| 28 | Brush Holder | 59 | Rand |

| 29 | Motor Back Support | 60 | Sealing Ring |

| 30 | Screw ST4 x 65 | 61 | Screw 35 |

| 31 | Microswitch | 62 | Bar |

Chainsaw Oil

- 1 Litre Chainsaw Oil (Part Number: 3050865)

- 1 Litre Biodegradable Chainsaw Blade Oil (Part Number: 3050866)

Foresty Products

- ECSS2 Electric Chainsaw Sharpener (Part Number: 3402077)

- CCLH1 Chainsaw Log Horse (Part Number: 3402085)

- V6 Vertical Electric Log Buster (Part Number: 3402150)

- H4 4 Tonne Horizontal Electric Log Buster (Part Number: 3402152)

Specifications

| Rated voltage | 230V @ 50Hz |

| Motor power rating | 2000W |

| Ampage | 4A |

| RPM @ 230V | 8200rpm |

| IP Rating | IPX0 |

| Insulation Class | Class II |

| Oil Capacity | 150ml |

| Oil Type | Clarke Chainsaw Oil. |

| Dimensions (D x W x H) | 245mm x 850mm x 280mm |

| Weight | 6.4kg |

| Bar Length | 405mm |

| Effective Cutting Length | 370mm |

| Chain Type | 3/8” Pitch, 1.27mm Thick, 56-57 Links |

| No Load Chain Speed | 15m/s |

| Chain stopping time (Kickback & Handle Release) | < 0.13 seconds |

| Noise & Vibration Data | |

| Sound Pressure Level | 103.09dB LwA |

| Sound Power Level | 106.09dB LwA |

| Guaranteed Sound Power Level | 110dB LwA |

| Uncertainty Factor | 3dB |

| Vibration Level | Front Handle – 2.6m/s2 Rear Handle – 2.233m/s2 |

| Uncertainty Factor | 1.5m/s2 |

Troubleshooting

| Problem | Possible Cause | Recommended Actions |

| Motor stops while cutting | The chain is pinched in a cut | Undercut the limb to relieve pressure on the limb. See the ‘Cutting’ section on page 2329 |

| The cord is damaged or severed. | If the extension cord is damaged, DO NOT use it and replace it. If the chainsaw cord is damaged, DO NOT use it and contact an approved service location | |

| The chain brake is engaged | Set the front hand guard to the operating position as described in ‘Checking the Front Hand Guard Position’ on page 14 | |

| Motor does not run or runs intermittently | The saw is not plugged in | Plug in the saw |

| The cord is damaged or severed | If the extension cord is damaged, DO NOT use it and replace it. If the chainsaw cord is damaged, DO NOT use it and contact an approved service location. | |

| The outlet fuse is tripped. | Unplug the extension cord, reset the fuse, and plug the extension cord back in | |

| Bad electrical outlet | Plug the extension cord into a different outlet | |

| Chain brake engaged | Set the front hand guard to the operating position as described in ‘Checking the Front Hand Guard Position’ on page 14 | |

| Trigger lockout not pressed | Press the trigger lockout before squeezing the trigger, see page 20 | |

| Debris is the side cover | Unplug the chainsaw, then remove the side cover and clean out debris | |

| The motor does not stop when chain brake is engaged | Debris is preventing the full movement of the front hand guard | Clean debris from the external chain brake mechanism |

| Possible chain brake malfunction | DO NOT USE. Warning: Operating a chainsaw without a functioning chain brake could lead to serious personal injury. Contact an approved service location before using. |

Guarantee

This CLARKE chainsaw is guaranteed against faulty Clarke CECS405D Electric Chainsaw manufacture for 12 months from the date of purchase. Please keep your receipt as proof of purchase. This guarantee is invalid if the chainsaw is found to have been abused or tampered Clarke CECS405D Electric Chainsaw with in any way, or not used for the purpose for which it was intended. Faulty Clarke CECS405D Electric Chainsaw goods should be returned to their place of purchase; no chainsaw can be returned to us without prior permission. This guarantee does not affect your statutory rights.

Environmental Policy

Through the purchase of this chainsaw, the customer is taking on the obligation to deal with the WEEE in accordance with the WEEE regulations in relation Clarke CECS405D Electric Chainsaw to the treatment, recycling & recovery, and environmentally sound disposal of the WEEE.

Customer Service

- Call: 0208 988 7400

- Website: parts@clarkeinternational.com

- Visit: service@clarkeinternational.com

FAQs

What safety precautions should I take before using the Clarke CECS405D electric chainsaw?

Wear protective gear at all times, such as robust footwear, safety goggles, gloves, and ear protection. Keep onlookers at a safe distance and use the chainsaw on level terrain.

How do I properly charge the Clarke CECS405D battery?

Make sure you only use the charger that came with your chainsaw. After plugging the charger into an appropriate power socket, connect it to the battery. Before using the battery for the first time, let it fully charge in a cool, dry place. Once completely charged, disconnect to prevent overcharging.

How do I adjust the chain tension on the CECS405D?

Although the chain should be tight, it should still be manageable. After adjusting, firmly tighten the guide bar nuts again.

What type of oil should I use for the chain lubrication?

Make use of premium bar and chain oil made especially for electric chainsaws. Avoid using motor oil or other lubricants as a substitute since they could harm the system or result in subpar performance.

How long does the battery typically last on a full charge?

Generally speaking, a full charge will enable roughly 30 to 45 minutes of continuous cutting under typical circumstances, while battery life varies depending on usage intensity.

Can I replace the chain myself, and how often should I do it?

Yes, by following the instructions in the instruction booklet, you may replace the chain.

What should I do if the chainsaw stops suddenly during operation?

Release the trigger right away, then switch off the chainsaw. Verify the chain tension, battery charge, and any potential blockages. Check for damage or overheating. For additional instructions, consult the manual’s troubleshooting section.