Clarke CEW2 English Wheel Metal Worker

Introduction

Thank you for purchasing this CLARKE English Wheel. This English Wheel is suitable for forming and shaping light-gauge steel and aluminium panels and for removing dents, smoothing hammer marks, flattening welds, etc. Pressure is applied by adjusting the lower anvil roller. Standard anvil rollers are supplied as listed in the specification. Before attempting to use this product, please read this manual thoroughly and follow the instructions carefully. In doing so, you will ensure the safety of yourself and that of others around you, and you can look forward to your purchase giving you long and satisfactory service.

Safety Instructions

- ALWAYS study these instructions before operating and pay close attention to all warnings.

- ALWAYS keep the work area clean and well-lit. Cluttered and dark areas invite accidents.

- ALWAYS secure the English Wheel to a solid workbench before use.

- ALWAYS keep the work area free of obstructions.

- Stay alert, watch what you are doing and use common sense when you are using this equipment. DO NOT operate this tool when you are tired, ill or under the influence of alcohol, drugs or medication.

- DO NOT overreach. Keep your proper footing and balance at all times.

- Concentrate on the job in hand, no matter how trivial it may seem. Be aware that accidents can be caused by carelessness due to familiarity.

- DO NOT wear loose clothing or jewellery which may get caught in moving parts. Wear a protective hair covering to contain long hair.

- Keep equipment clean for the best and safest performance. Check for misalignment or binding of moving parts, broken parts, or any condition that may affect the tool’s operation. If damaged, have the tool repaired before use.

- ALWAYS hold the workpiece securely. Large work pieces should always be well supported to avoid loss of control.

- Sheet metal may have sharp edges. ALWAYS wear gloves when handling sheet metal and use caution when bending and cutting.

- Rollers are heavy; take care when handling and keep your hands away from contact areas.

Inventory

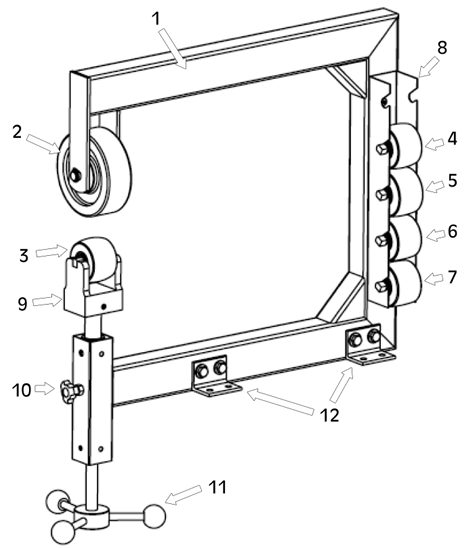

- Frame

- Upper Wheel 149mm x 51mm

- Lower Wheel 3”(7.6cm) Radius

- Lower Wheel 4”(10.1cm) Radius

- Lower Wheel 5”(12.7cm) Radius

- Lower Wheel 6”(15.2cm) Radius

- Lower Wheel 8”(20.3cm) Radius

- Lower Wheel Storage Rack

- Lower Wheel Bracket

- Locking Nut

- Adjustment Handle

- Mounting Brackets

Mounting

- The forces exerted on the English Wheel during operation are substantial. The English Wheel must be firmly secured to a workbench or table that will support the weight and dynamic pressures of the operation.

- Make sure that you have a suitable workbench setup for the English Wheel before performing the assembly.

Assembly

- Before you start assembling your English Wheel, you will require the following tools: • 2 x 17mm spanners or adjustable wrenches

- 3/16 hex key

- a pair of circlip pliers

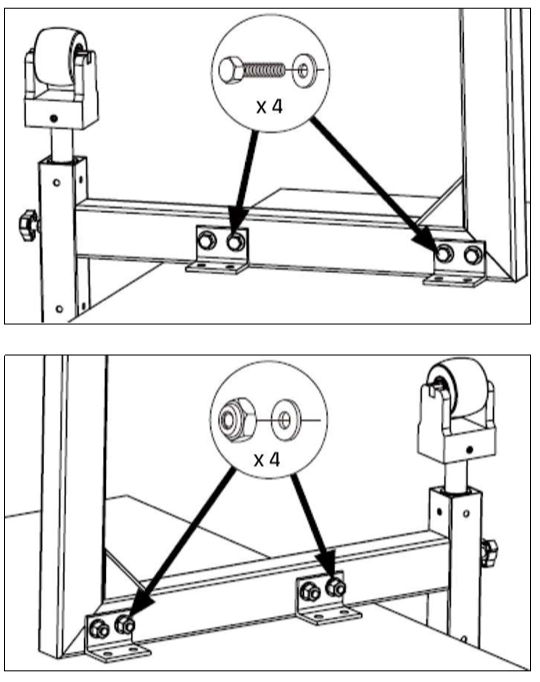

- Attach the 4 mounting brackets to the frame with the M10-1.5 x 80 hex bolts, 10mm flat washers and M10.15 locking nuts supplied.

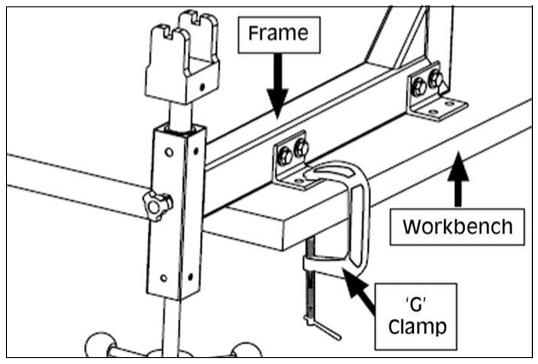

- Mount the frame to a workbench using the mounting brackets, making sure there is clearance for the adjustment handle.

- If you are not ready to permanently mount the frame to a workbench, you can temporarily secure the frame to the workbench with ‘G’ clamps, as shown.

- If you are not ready to permanently mount the frame to a workbench, you can temporarily secure the frame to the workbench with ‘G’ clamps, as shown.

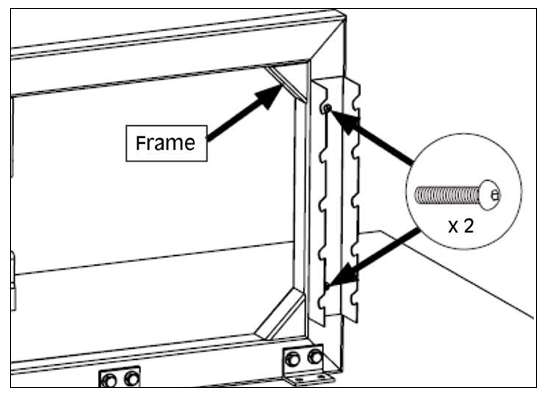

- Attach the lower wheel storage rack to the frame using the M6-1 x 10 hex cap screws supplied.

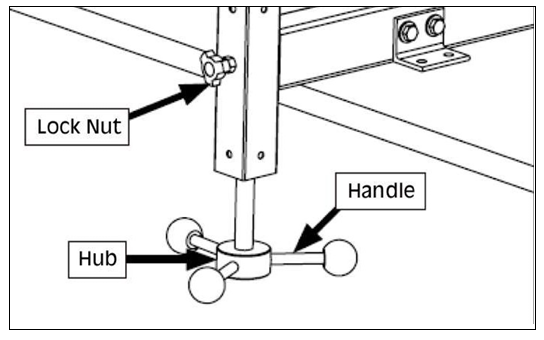

- Attach the 3 adjustment handwheel handles to the handwheel nub. Secure the handle by tightening the locking jam nut.

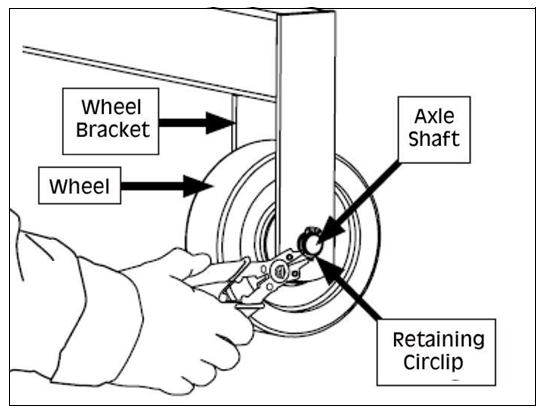

- Attach the upper wheel to the wheel bracket using the axle shaft and a retaining circlip on each side.

Replacing the Lower Wheel

This English Wheel comes with 5 (3”, 4”, 5”, 6” & 8” radius) crowned anvils (lower wheels) that will accommodate most curving operations.

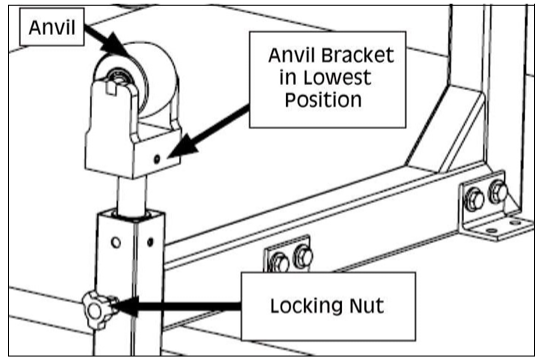

- Loosen the locking jam nut and lower the anvil bracket to its lowest position using the handle.

- Remove the anvil and replace it with the required one.

- Using the handle, raise the anvil bracket to the operating position and lock the nut in position.

Operation

- Insert the sheet metal workpiece between the upper and lower wheels.

- Turn the lower wheel adjustment handle to raise the lower wheel and gently pinch the workpiece.

- Minor adjustments to the gap between the wheels can be made by raising or lowering the adjustment handle.

- Pinching it tightly will make it harder to pass the metal through the wheels and may cause unwanted creasing.

- Pinching it loosely makes work easier and Clarke CEW2 English Wheel Metal Worker therefore more accurate. However, it may take more passes to form the required shape.

- Before starting to work on the metal, turn the locking jam nut clockwise until tight to lock the lower wheel in position.

- Begin forming the metal by pushing and pulling it through the wheels.

Maintainance

Always inspect the wheels before use and ensure they are in top condition. Check that all moving parts move smoothly and freely. After use, keep the rollers clean and occasionally lubricate moving parts with a light oil. This will also inhibit any corrosion of the metal components.

Exploded Diagram

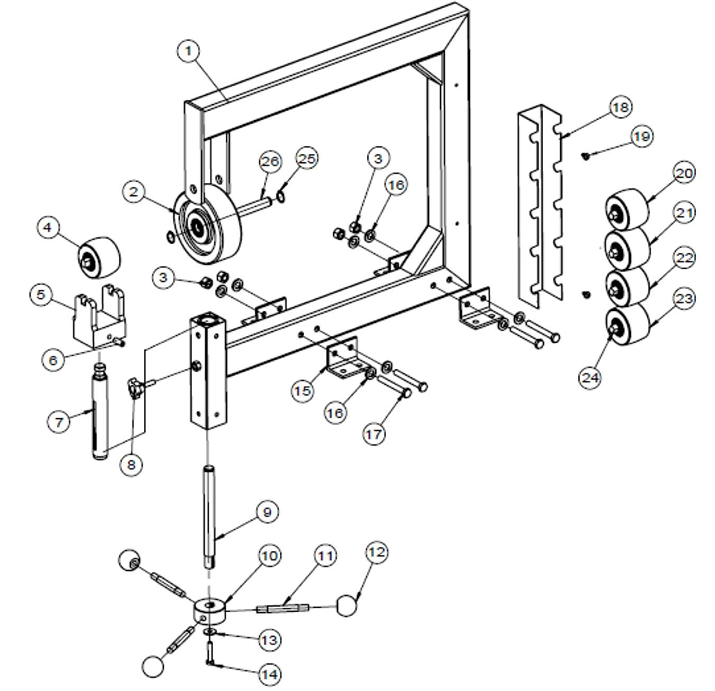

- Frame

- Top Wheel

- Lock Nut M10

- Lower Anvil 3” Radius

- Anvil Bracket

- Set Screw M10

- Anvil Bracket Shaft

- Locking Nut

- Leadscrew

- Handle Hub

- Slotted Bolt

- Handle Knob

- Flat Washer 8mm

- Cap Screw M8

- Mounting Bracket

- Flat Washer 10mm

- Hex Bolt M10

- Anvil Storage Rack

- Button HD Cap Screw

- Lower Anvil 4” Radius

- Lower Anvil 5” Radius

- Lower Anvil 6” Radius

- Lower Anvil 8” Radius

- Anvil Shaft

- Circlip Retaining Ring

- Top Wheel Shaft

Metalworking Product

Bench Vice – CV150B

- 150mm Jaw Width

- 160mm Jaw Opening

- 75mm Jaw Depth

- Part No. 6504011

3 in 1 Sheet Metal Machine – SBR610

- Bends, Slip Rolls & Shears Sheet Metal:1mm

- Minimum Rolling Dia.: 39mm

- Part No. 6560005

Sheet Metal Folder – CMF24B

- Max Sheet Steel Capacity:22 swg (0.71mm)

- Max. Width Capacity: 600mm

- Part No. 7630067

150mm Sheet Metal Shears – CPS150B

- Sheet Cutting Capacity: 5mm

- Bar Cutting Capacity: 8mm Dia.

- Part No. 1700261

Double-Headed Metal Nibbler- DHC-2

- Max Cutting Cap.: Steel Plate – 1.8mm, Stainless Steel – 1.2mm, Copper – 2mm, Plastic – 2mm

- Part No. 6500233

10” Tin Snips – CHT308

- Max Cut: Rolled Sheet Steel: 0.8mm

- Part No. 1801308

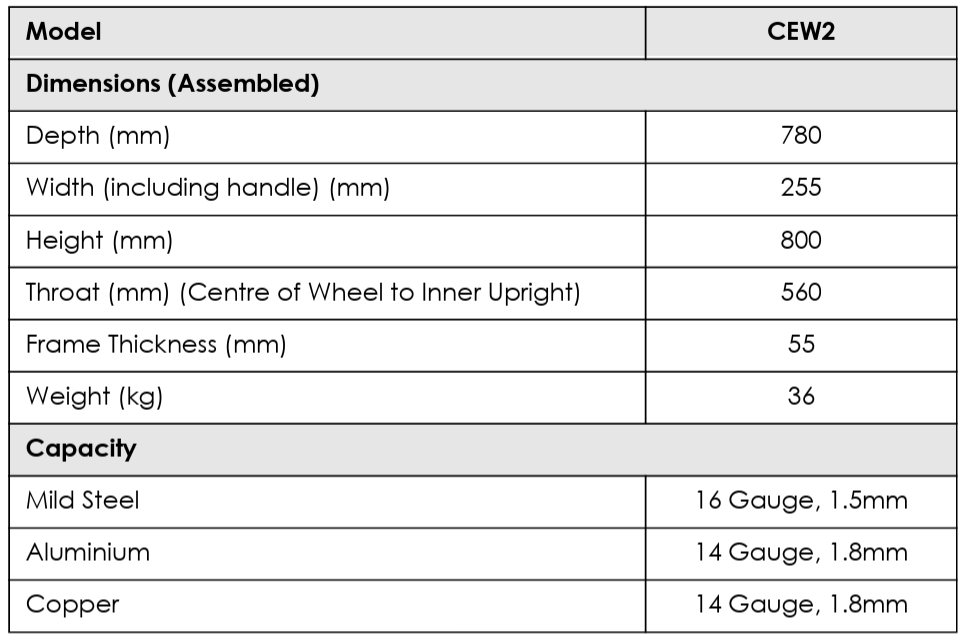

Specification

Guarantee

This product is guaranteed against faulty manufacture for a period of 12 months from the date of purchase. Please keep your receipt, which will be required as Clarke CEW2 English Wheel Metal Worker proof of purchase. This guarantee is invalid if the product is found to have been abused or tampered with in any way, or not used for the purpose for which it was intended. Faulty goods should be returned to their place of purchase; no product can be returned to us without prior permission. This guarantee does not affect your statutory rights.

Customer Service

- Tel: 0208 988 7400

- Website: parts@clarkeinternational.com

- Visit: service@clarkeinternational.com

FAQs

What is the Clarke CEW2 English Wheel used for?

With the Clarke CEW2, users can precisely shape and smooth sheet metal to make curved panels, car body parts, and metal sculptures.

What thickness of metal can the CEW2 English Wheel handle?

Depending on the type of metal (steel, aluminium, etc.), the CEW2 can efficiently work on sheet metals that range in thickness from 0.3 mm to 1.2 mm (usually 24 to 18 gauge).

How do I adjust the pressure between the rollers?

You may establish the ideal force for your particular metal thickness and shaping needs by adjusting the pressure with the tensioning wheel or knob.

What types of metals are suitable for use with this English Wheel?

Brass, copper, aluminium, and mild steel are the ideal materials for it. Steer clear of extremely thick or tough metal, as it could harm the equipment.

How do I set up the English Wheel for the first time?

Attach the upper wheel, put the desired anvil (lower wheel), secure the unit to a stable workbench, and turn the pressure knob in accordance with the metal gauge.

Can I change the anvil wheels on the CEW2?

Secure the unit to a sturdy workbench, attach the upper wheel, place the required anvil (lower wheel), and adjust the pressure knob in accordance with the metal gauge.

What safety precautions should I take when operating the English Wheel?

Make sure the machine is placed firmly before using it, keep your hands away from moving rollers, and wear gloves and eye protection.

How do I maintain the English Wheel to ensure long-term performance?

Maintain the wheels clean and clear of debris, oil the moving part regularly, and check for wear or damage. To avoid rust, store in a dry location.