Clarke CMF24C 610MM Metal Bender

Introduction

Thank you for purchasing this CLARKE Metal Bender. Before attempting to use it, please read this manual and carefully follow all instructions given. In doing so, you will ensure the safety of yourself and that of others around you, and you can also look forward to the product giving you long and satisfactory service.e

Safety Instruction

- Due to the weight of the metal folder, the help of an assistant may be beneficial during unpacking and mounting.

- ALWAYS wear gloves when handling sheet metal with sharp edges.

- ALWAYS operate on a suitably strong bench with adequate light.

- Leave adequate working space around the folder for safe and convenient operation.

- ALWAYS check for signs of structural damage before starting work. DO NOT use if damage is found. Have repairs made only by a CLARKE service centre.

- ALWAYS ensure the workpiece is secure and properly positioned before applying pressure. ALWAYS keep hands and fingers away from moving parts that may pinch.

- NEVER use extension tubes to increase the length of the handles. Excessive effort can cause damage and/or accidents.

- EVER attempt to bend materials that exceed the sizes stated above.

Failure to heed these warnings may result in damage to the equipment or personal injury.

Method of Use

Mount the Metal Folder in a vice, at a height which allows easy operation, taking into account the nature of the work, with the handles pointing towards you.

- Lower the handle until the moving plate becomes parallel to the workbench.

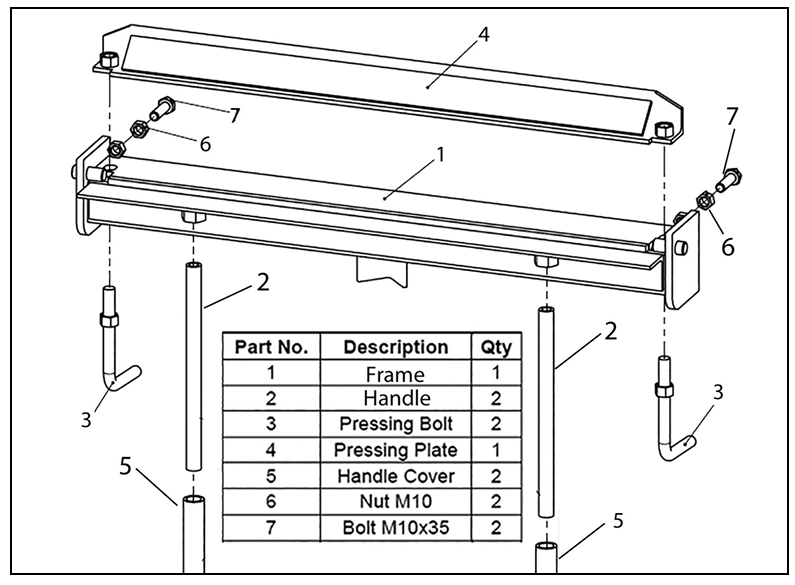

- Turn the bolt (7) to adjust the gap between the front edge of the pressing plate (4) and the moving plate to the required radius and tighten the nut (6).

- Position the workpiece on the supporting plate and the moving plate so that the edge to be ent, lines up with the back edge of the supporting plate.

- Place the pressing plate (4) on top of the Clarke CMF24C 610MM Metal Bender supporting plate so that the back edge of the Pressing Plate lines up flush with the back edge of the Supporting Plate.

- Turn the handle (2) until the pressing plate (4) presses the workpiece

- Raise the two handles (2) to bend the material.

Guarantee

This CLARKE generator is guaranteed against faulty manufacture for 12 months from the date of purchase. Please keep your receipt as proof of purchase. This guarantee is invalid if the generator is found to have been abused or tampered with in any way, or not used for the purpose for which it was intended. Faulty goods should be returned to their place of purchase; no chainsaw can be returned to us without prior permission. This guarantee does not affect your statutory rights.

Environmental Policy

Through the purchase of this generator, the customer is taking on the obligation to deal with the WEEE in accordance with the WEEE regulations in relation to the treatment, recycling & recovery, and environmentally sound disposal of the WEEE.

Customer Service

- Call: 0208 988 7400

- Website: parts@clarkeinternational.com

- Visit: service@clarkeinternational.com

FAQs

What materials can the Clarke CMF24C metal bender handle?

Round rod, square, bar, and flat bar work best with it. To prevent overloading, always verify the material’s thickness and width limitations.

What is the maximum bending capacity of this tool?

Depending on the hardness of the material, the CMF24C can bend flat steel up to 610mm (24″) wide and 6mm thick.

Is the metal bender suitable for making complex shapes or curves?

Indeed, the CMF24C is capable of performing a variety of bends, such as angles, S-bends, U-bends, and scrolls. It is feasible to create ornamental and useful metalwork for gatesframesfrs and brackets with practice and the right die setup.

How do I secure the metal bender during use?

Using the pre-drilled holes in the frame, fasten the device firmly to a sturdy workbench or mounting platform. When bending heavy materials, this guarantees precision and safety.

Does the CMF24C require any power source?

No, the CMF24C is a manual metal bender that uses a lever to operate. It is perfect for both workshop and on-site use because it doesn’t require electricity or hydraulic power.

Can this bender be used for stainless steel?

Because of its greater strength, it can bend stainless steel of lower grades; however, the outcomes may differ. Frequent or excessive bending of stainless steel may cause the tool to wear down more quickly. Always start by testing a little portion.

What maintenance does the CMF24C require?

It requires little upkeep. To stop rust, keep all moving parts clean and lightly oiled. Check for loose or worn parts frequently, and tighten bolts as necessary. When not in use, store in a dry location.