Vevor WX4400LBS-2 Electric Chain Hoist

Safety First

Any hoisting equipment may have potential risks to could cause personal injuries or property damage. If operators do not follow the proper operation instructions and pay no attention to precautions, the occurrence of risks will greatly increase. Thus, it isrequiredthatevery every operator should read through and be familiar with the operation manual and precautions before operation to ensure safe operation. If any part of the manual has the alarming signs as indicated at the right andleftand the part is underlined, it indicates that the part is a vital safety description or precaution. And operators must fully follow, otherwise, it may endanger the operators or others, or property. Hence, before operating the electric chain hoist, please read through the manual and the precautions.

Preface

The manual can assist you in correctly installing, operating, and maintaining your electric chain hoist. Ensure your hoist operates safely with the highest efficiency. Before you use the hoist, please read through the manual to know about the correct procedure and operation, as well as preventative maintenancetoguarantee you to have faithful and reliable service.

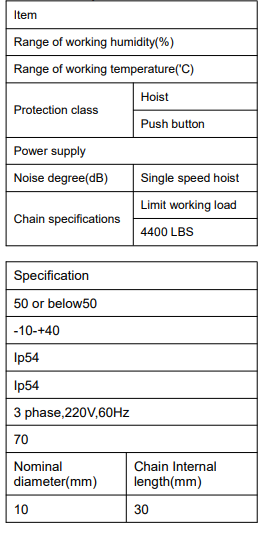

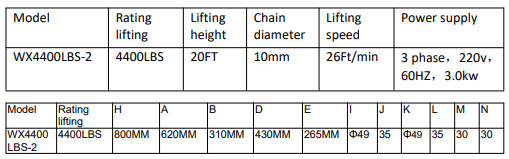

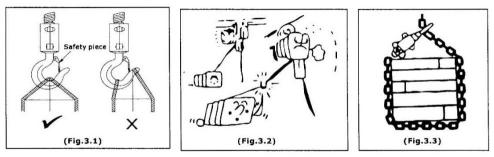

Main Specifications

Table of Specifications

Remarks

- If your working temperature and humidity are out of the range of the tool, please ask your distributor for related data.

- Expected operation ways: The hoist is designed to vertically lift in normal atmospheric and working conditions.

- The standard of noise degree is the value measured at 1 meter from the machine under normal operation.

Safety Devices

- Side magnetic braking device. It is a unique design that is characterized by the ability that the brake to act immediately as soon as the electric power is cut off.

- Hooks and Safety Latch The hook is hot forging with high tensile steel and heat-treated to meet the demands of strength and hardness. The operational safety of the lower hook is ensured by its 360° rotation and safety latch.

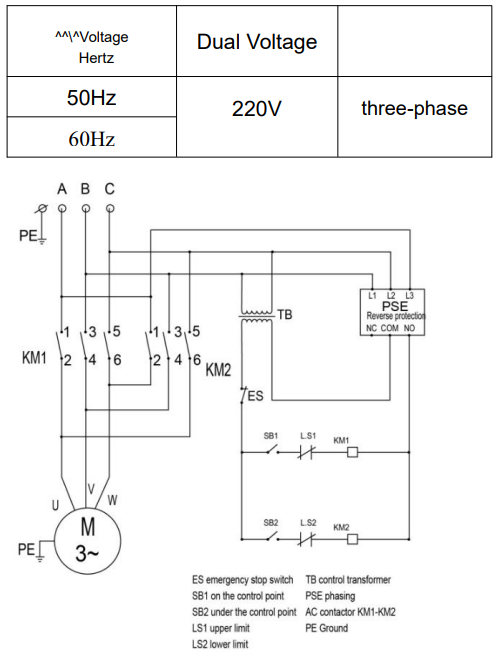

- Anti-phase Protecting Device: It is a special design to prevent the circuit from not working and protect the electric motor from being burned in case of wiring error in the power supply.

- Limit Switch: It is installed where the weights are lifted on and off to make the motor stop automatically, so as to prohibit the chains from exceeding for safety.

Safety Rules

Danger

The hoist is not designed for supporting the loading of persons. Any modification, which includes upgrade and lifting change, or any hoist design change, must be done by the original manufacturer or r qualified professional engineer.

Danger

It is forbidden to operate the hoist in an explosive environment.

- A person who has related training and experience can operate the hoist

- Before the operation, please confirm the following:

- Use the proper lifting rope.

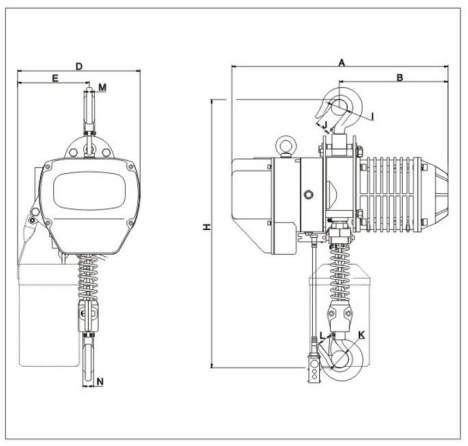

- The location of the cable should be as indicated in the following diagram (Fig. 3.1), and the safety latch must lock the hook correctly.

- Make sure the weights are safe and firm, then lift them.

- The button must be operated stably and firmly.

- Try my best to avoid excessive inching operations.

- Be sure that the motor has been completely stopped before operating in the reverse direction.

- After finishing the operation, keep the control cable and the lower hook vertically and statically.

- When lifting, the weights must be kept balanced. Never lift weights that are not in balance.

- It is forbidden to drag the weights horizontally. (see Fig. 3.2)

- It is forbidden to lift the weights by using the chain to bind the weights.(seeFig3.3)

- When in operation, the operators must face and pay attention to the weights. Be sure not to turn back to or overlook it.

- It is risky to lift the weights over the rated load capacity. And it should not be tried.

- Do not lift goods when the chain is twined.

- Regular inspection to ensure the chain is in good condition. If the chain is damaged, don’t operate the hoist to lift the weights.

Warning: Never use the chain as a welding electrode

Warning: Never stand under when lifting

Installation

Voltage

Note: If the voltage of the power supply is over or less 10% than standard voltagetooperatehoist under the abnormal voltage conditions will result in motor damage; hence, before operation, be sure to confirm whether the voltage of the power supply is within the standard range.

Installation

Warning: It is forbidden to link the power supply before the completion of installation. Before installing the hoist, please confirm the whole upper hook assembly has been firmly assembled to the hoist body (ensure the chain connection pin is installed properlRemarksaks If the hoist is equipped with an electric trolley, the first step(to separate the upper hook from the hoist body) can be omitted, and it is only required to install the hoist between two side plates of the trolley and lock the upper hook. Assemble chain bag (Fig.4.1).

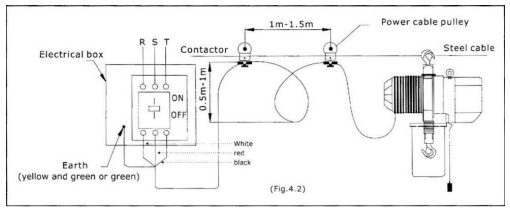

Link the power supply and operate the push button. The procedure should be performed by a professionally trained person. (Fig.4.2)

Operation Test

- Press the(S) push button to lower the hoist until the limit spring touches the limit switch, and the motor will stop automatically.

- Press the(D) button until the chain is totally in the chain bag and the motor stops.

- Test the function of the emergency stop switch (if the emergency stop switch is selectively purchased). Ed, Press button (J) or (S), and press the emergency stop switch at the same time to check whether the hook can stop immediately. When the emergency switch is pressed, there will be no response when any other button is pressed. Finally turn the emergency switch counterclockwise,,e and it will bbbounceack totto theiginal position. When it bounces back, the hoist can be operated again if one of the above-mentioned tests is required to check the distribution circuit and the self-locking of the emergency switch.

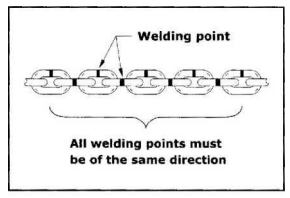

- Check the direction of the chain. All welding points should be in the same direction. (Fig. 4.3. The operation can not be utterly proper unless all the welding points of the chain are in the same line .

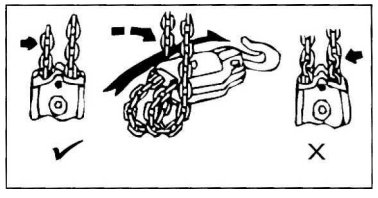

Note: If the chainfalla is double or ennumberedit is forbidden to hang the lower in the reverse direction to avoid dangers(Fig. 4.4).

- Chain lubrication. The degree of chain lubrication plays an important role in service life. It needs to apply machine oil or gear oil regularly to prolong the service life. The process of lubrication:

- Keep the chain vertically without a load.

- Erase dust and water stains on the can.

- Lubricate each link of the chain connection and the load pulley. After the lubrication, lift the chipper assist hood to apply lubrication evenly. (Fig.4.5)

OPERATION

Danger: After the above-mentioned test and operation testing, the hoist can be normally operated.

Warning: It is forbidden to link the power supply before the completion of installation.

Maintenance and Overhaul

Except for monthly examination of the performance of the brake and limit switch, it is maintained under loading conditions.

Danger: Before maintenance, be sure to label “danger” and”overhaul” on the power supply and controller.

Maintenance

- When the gear operation times reach more than 500 hours, check the amount of lubrication, and later check the lubrication every 3 months regularly.

Remarks: We recommend using the engine oil the same as ISOVG46 oil. - Check the dryness of the hoist parts frequently, and forbid toabusethehoist; otherwise, its durability may be reduced.

- If it is operated outdoors, please add a protection cover.

Overhaul

Daily inspection: before daily operation, please check the following items:

- Proper power supply.

- Test the “up”, “down,” and “emergency stop” (if installed) without load.

- The motor works normally.

- There is no abnormal or excessively high noise.

- The safety latch of the lower hook functions properly and is free of faults.

- The rotatable or movable parts and the limit switch, as well as the brake function,t, normally work.

- The chain is lubricated well.

Monthly inspection

Warning: During maintenance, please use the original parts recommended by the manufacturer.

Chain

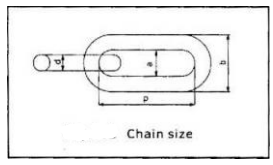

Any distorted, extended, or worn chain will not be a good locked chainwheel, resulting in the breakdown or disengagement of the chains. To ensure the safe and normal operation, the internal length and width, external width of the chain must be checked monthly. In the following situation, the chain must be replaced.

- The internal length of the chain (p) is worn and extended 5% higher than the values as listed in Table 6.1

- The wearing of the diameter of the chain link (d) is lower than the value listed in Table 6.1 (The wearing of the nominal diameter reaches 10% higher than the original one) ****** When the wearing of the chain is high, be sure to confirm the wearing of the chain wheel and chain guide ******

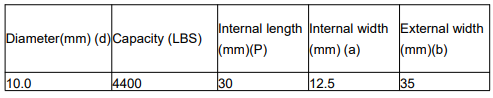

Hoist hook

Check the hook carefully. Its the crack or distortion is over 5% of the original one, it should be replaced. (Please refer to the sizes in the following table.)

Limit switch

Warning: It should be inspected by a qualified electrician. Check whether the limit switch operates normally. After clearing, make it covered with a thin layer of lubricant to ensure normal operation. (3)Annual overhaul

Warning: The annual maintenance should be performed by

- Check whether the locking of the gear is excessively worn or damaged.

- Replace the oil gearbox thoroughly. After the above-mentioned checking and machine reassembling, lift up and down with the weights several times before normal operation. If it is in good condition, then restart the operation.

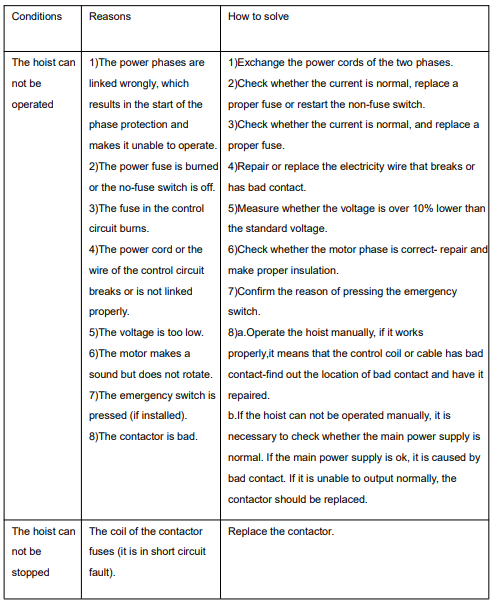

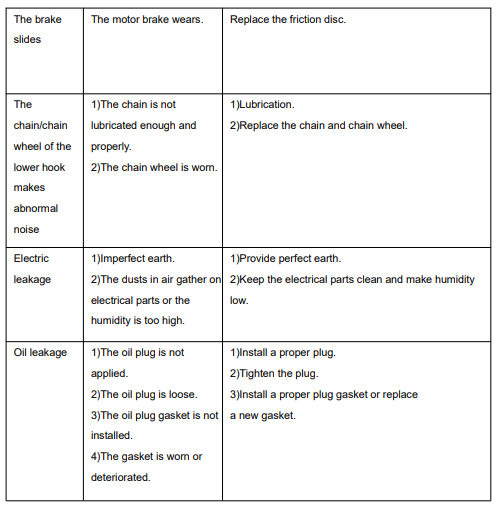

Troubleshooting

Common problems and Processing

Instructions for Using and Inspecting Electric Chain Hoist

Caution: When using the electric chain hoist, conduct the following items:

- Confirm that the ISO level of the electric chain hoist in use is by the operating conditions.

- No overloading.

- The electric chain hoist must be equipped with the appropriate chain.

- It is forbidden to use if tit he lifting height of the electric chain hoist is short.

- Daily check-up before use.

- Before use, check chains and links to see whether they are loose, twisted twined. Make maintenance before use.

- It is forbidden to use if the anti-separation device of the lower hook is invalid or lacking.

- It is forbidden to chain it lacks of up and down stop device.

- It is forbidden to use the chain if it is twined with the weights.

- It is forbidden to use the front end of the hook to lift the weights.

- Do not make repeated operations of lifting up and down rapidly.

- Do not lift beyond the up and down limit switch.

- Do not walk or stand under the hoist when lifting.

- Do not lift the weights slanting(within 15 degrees)

- Prevent the electric chain hoist from falling.

- If the operation frequency is high, the chain of the electric chain hoist should be replaced annually.

- Under the following special conditions, such as below-40℃, above100℃corrosiveor orexplosive environment, the chain should be replaced every six months, and the lower hooshould beebe replaced every two years. (If the operation frequency is high, the lower hook should be examined annually and replaced every two years.)

- In the electroplate, heat treatment plant, the surface of the hoist shouldbedoperiodic inspected monthly, and the chain should be replaced annually.

- After breaking, the chain can not be welded by yourself.

- The chain should be lubricated before operation.

- Gears, bearings, and other friction parts shouldlubricatedatea timelymelyl manner.

- When not using the hoist for a long time, please safely keep it after doing proper rustproofing.

- Electric chain hoist users will not be permitted to modify, if necessary, commission the factory to do so.

- It should be avoided to lift the weights with two hoists at the same time, which is dangerous. If in extreme circumstances, it should be lifted carefully within the range of sufficient loading capacity.